Intelligent factory supervision method

A factory and intelligent technology, applied in the field of smart factory supervision, can solve problems such as inability to manage unified management, manpower shortage, and large investment in supervision manpower, and achieve the effects of unified data standards, high intelligence, and low labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

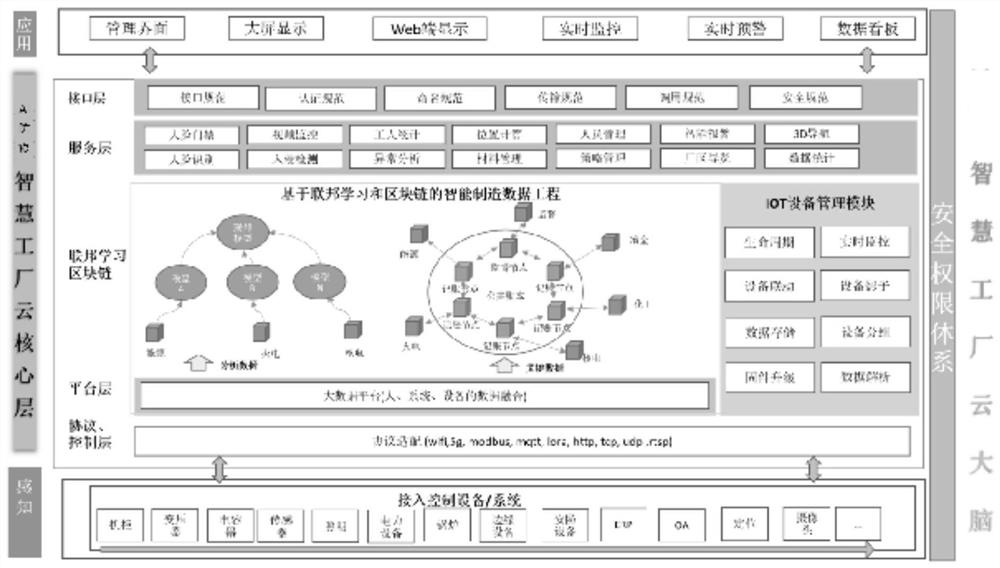

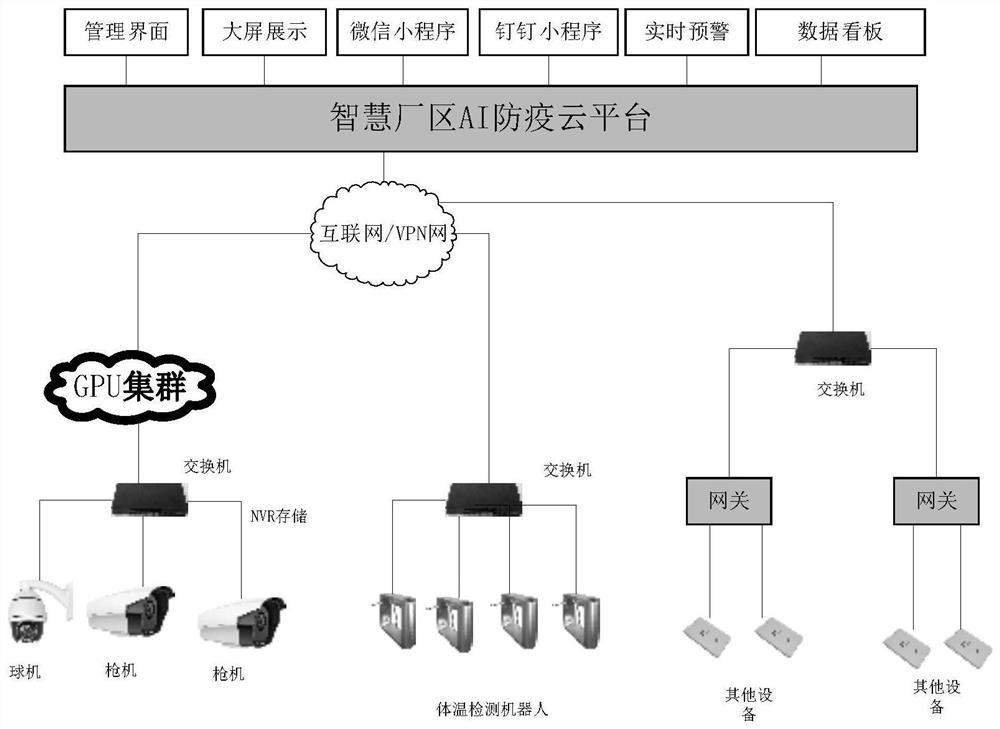

[0037] Such as figure 1 As shown, the smart factory supervision method in this embodiment can be realized through the smart factory supervision system. The smart factory supervision system includes a cloud server with computing and control functions, and also includes a visual machine and an access control gate connected to the cloud server. , various terminals, personnel identification cards, etc. Various information can be viewed through the application on each terminal according to the authority.

[0038] A smart factory regulatory approach includes the following.

[0039] According to the organizational structure or occupational position of the enterprise, the staff is classified, and the identity information and classification information of each staff are stored in the cloud server accordingly, and specific managers have the authority ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com