A CNC machine tool fixture for motor shell processing

A technology for CNC machine tools and motor casings, applied in the direction of chucks, etc., can solve the problems of difficult to ensure coaxiality, high casing rejection rate, casing deformation, etc., to reduce casing damage, reduce rejection rate, and improve Axiality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

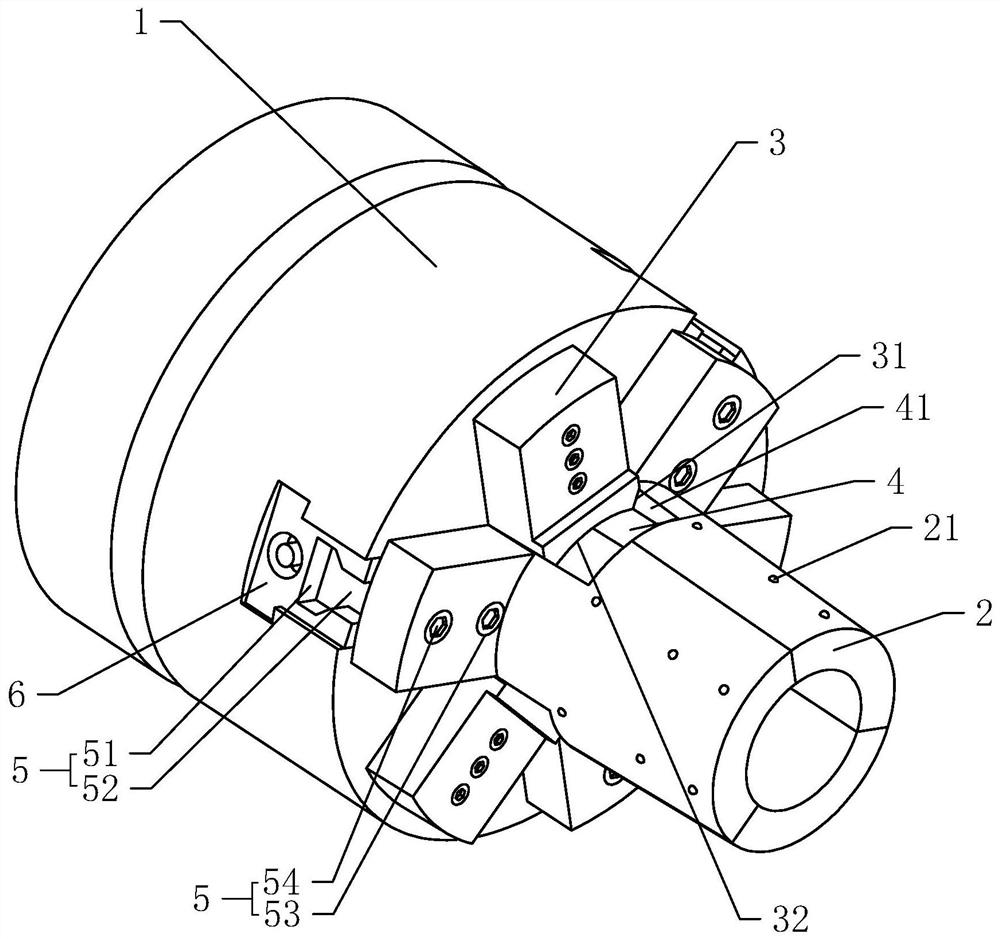

[0027] Such as figure 1 As shown, a CNC machine tool fixture for motor shell processing, including a hydraulic three-grip chuck 1, a centering support block 2, a centering block 3, and a positioning groove 4, and the hydraulic three-grab chuck 1 is fixed on the spindle of the CNC machine tool Above; the number of centering support blocks 2 is equal to the number of jaws 6 of the hydraulic three-grip chuck 1, fixed on the jaws 6 through the connection assembly 5, and the centering support blocks 2 are joined together to form a hollow centering column .

[0028] The diameter of the outer circle of the centering support block 2 gradually increases from the end away from the hydraulic three-grip chuck 1 towards the claw 6, so that the casing is set on the centering column formed by the centering support block 2. , when the centering support block 2 expands outw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com