Pipe end sealing equipment for steel-plastic composite pipe and using method of pipe end sealing equipment

A steel-plastic composite pipe and sealing equipment technology, applied in shearing machine equipment, metal processing equipment, pipe shearing device and other directions, can solve the problems of long time, low efficiency, poor quality, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

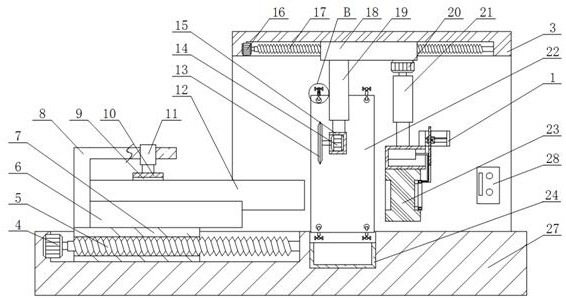

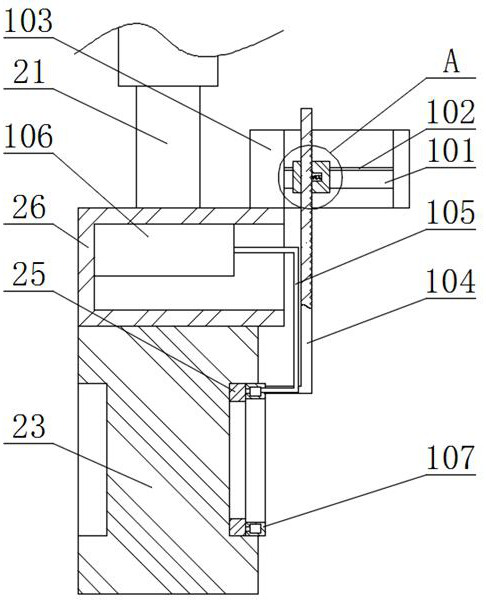

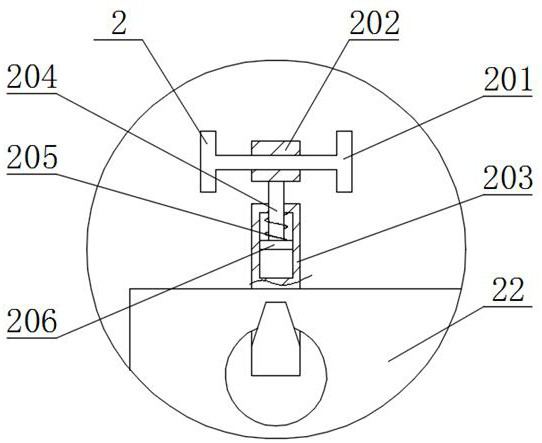

[0029] see Figure 1-7 , the present invention provides a technical solution:

[0030]A pipe end sealing device for a steel-plastic composite pipe and its use method, comprising a base 27 and a fixing seat 3, the top rear side of the base 27 is fixedly connected to the fixing seat 3, and the inner side of the left end of the fixing seat 3 is fixedly connected to the third motor 16 The end of the main shaft of the third motor 16 is fixedly connected with a second lead screw 17, and the second lead screw 17 is rotationally connected with the fixed seat 3, and the outer side of the second lead screw 17 is spirally connected with a first slider 108, and the first slider Block 108 is slidably connected with fixed seat 3, and the left side of the bottom end of first slide block 108 is fixedly connected with second electric telescopic rod 19, and the bottom end of second electric telescopic rod 19 is fixedly connected with protective shell 15, and the inner side of protective shell 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com