Method for improving productivity of cyclohexanol dehydrogenation device

A cyclohexanol and dehydrogenation technology, which is applied in the fields of dehydrogenation preparation, chemical instruments and methods, preparation of organic compounds, etc. Conducive to smooth operation, reduced dimerization, and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

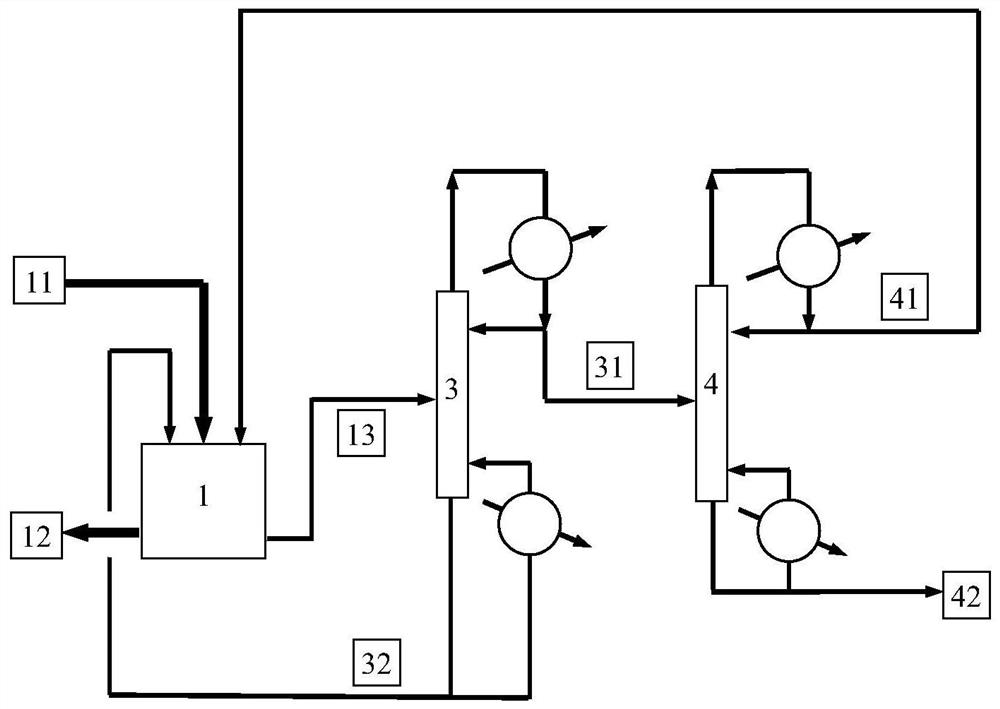

[0042] This embodiment adopts vacuum-atmospheric double-tower rectification to remove intermediate components:

[0043] The material crude alcohol from the top of the alcohol tower in the original production device is introduced into the crude alcohol tank, mixed with the refined refined alcohol as the material for the dehydrogenation process of decyclohexanol, and the flow rate is 12000kg / h. The material in the crude alcohol tank contains 91.22% of cyclohexanol, 4.13% of cyclohexanone and 4.65% of intermediate components.

[0044] The crude alcohol is sent to the middle part of the vacuum tower at a rate of 192.3kg / h for rectification and separation, and the bottom liquid of the vacuum tower is returned to the crude alcohol tank with a flow rate of 168.3kg / h; the distillate from the top of the vacuum tower is continuously discharged to Atmospheric tower, the flow rate is 24.0kg / h. The pressure at the top of the decompression tower is 3-4kPa, the reflux ratio is 15, the tempe...

Embodiment 2

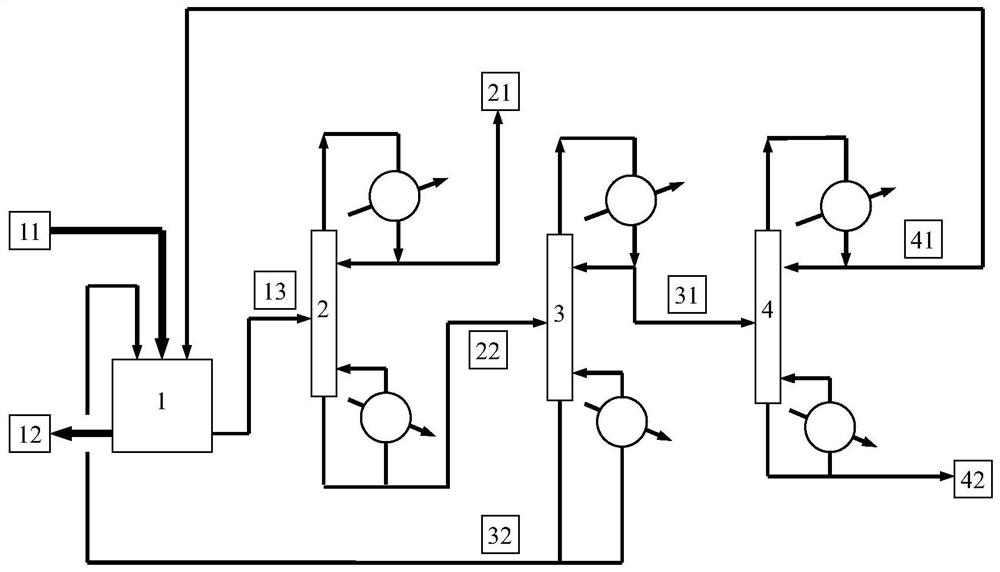

[0048] This embodiment adopts deketone-decompression-atmospheric pressure three-tower rectification to remove intermediate components:

[0049] The material crude alcohol from the top of the alcohol tower in the original production device is introduced into the crude alcohol tank, mixed with the refined refined alcohol as the material for the dehydrogenation process of decyclohexanol, and the flow rate is 12000kg / h. The material in the crude alcohol tank contains 91.34% of cyclohexanol, 4.04% of cyclohexanone and 4.62% of intermediate components.

[0050] The crude alcohol is sent to the middle of the crude ketone tower at a rate of 217.4kg / h for rectification and separation, and the bottom liquid of the crude ketone tower is discharged to the vacuum tower with a flow rate of 208.7kg / h; the distillate from the top of the crude ketone tower is continuously discharged To the crude alcohol and ketone tank, the flow rate is 8.7kg / h. The pressure at the top of the crude ketone tow...

Embodiment 3

[0055] This embodiment adopts vacuum-atmospheric double-tower rectification to remove intermediate components:

[0056] The material crude alcohol from the top of the alcohol tower in the original production device is introduced into the crude alcohol tank, mixed with the refined refined alcohol as the material for the dehydrogenation process of decyclohexanol, and the flow rate is 12000kg / h. The material in the crude alcohol tank contains 93.56% of cyclohexanol, 2.97% of cyclohexanone and 3.47% of intermediate components.

[0057] The crude alcohol is sent to the middle of the vacuum tower at a rate of 312.5kg / h for rectification and separation, and the bottom liquid of the vacuum tower is returned to the crude alcohol tank with a flow rate of 287.5kg / h; the distillate from the top of the vacuum tower is continuously discharged to Atmospheric tower, the flow rate is 25.0kg / h. The pressure at the top of the decompression tower is 3-4kPa, the reflux ratio is 15, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com