A method for operating SCR catalyst having bypass flow channel

An SCR catalyst, flow channel technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as reducing performance under cold start conditions, and achieve the effect of avoiding undesired oxidation and ensuring conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

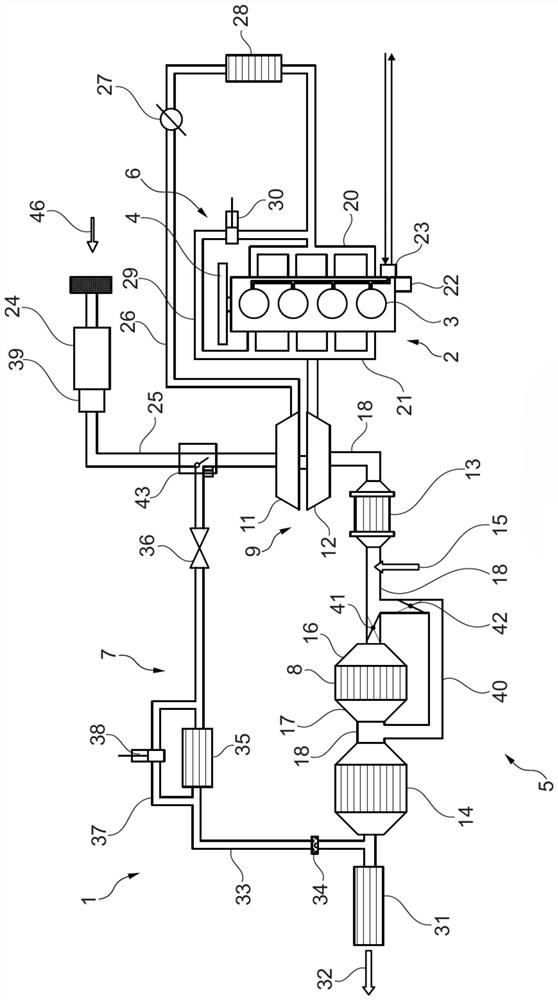

[0021] figure 1 The engine arrangement 1 shown schematically in FIG. 2 comprises an internal combustion engine 2 , an exhaust gas aftertreatment device 5 according to the invention, a high-pressure exhaust gas recirculation device 6 and / or a low-pressure exhaust gas recirculation device 7 . The engine arrangement 1 also includes a turbocharger 9 . The turbocharger 9 includes a compressor 11 and a turbine 12 .

[0022] The exhaust gas aftertreatment device 5 according to the invention contains an SCR catalyst 8 with an inlet 16 and an outlet 17 . An inlet valve 41 is arranged upstream of the inlet 16 . The inlet to the SCR bypass flow channel 40 of the bridging SCR catalyst is arranged upstream of the inlet valve 41 . SCR bypass flow passage 40 includes SCR bypass valve 42 . The SCR bypass flow passage 40 leads to the exhaust flow passage 18 immediately downstream of the outlet 17 of the SCR catalyst 8 . The device 15 for injecting urea into the flow channel 18 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com