A kind of method for tubular continuous preparation of β-menadione

A menadione, tubular technology, applied in the field of continuous production of β-menaquinone by using tubular reactors, can solve the problems of unstable quality between batches, large amount of one-time input material, difficult temperature control, etc. Achieve the effects of easy control, high production continuity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

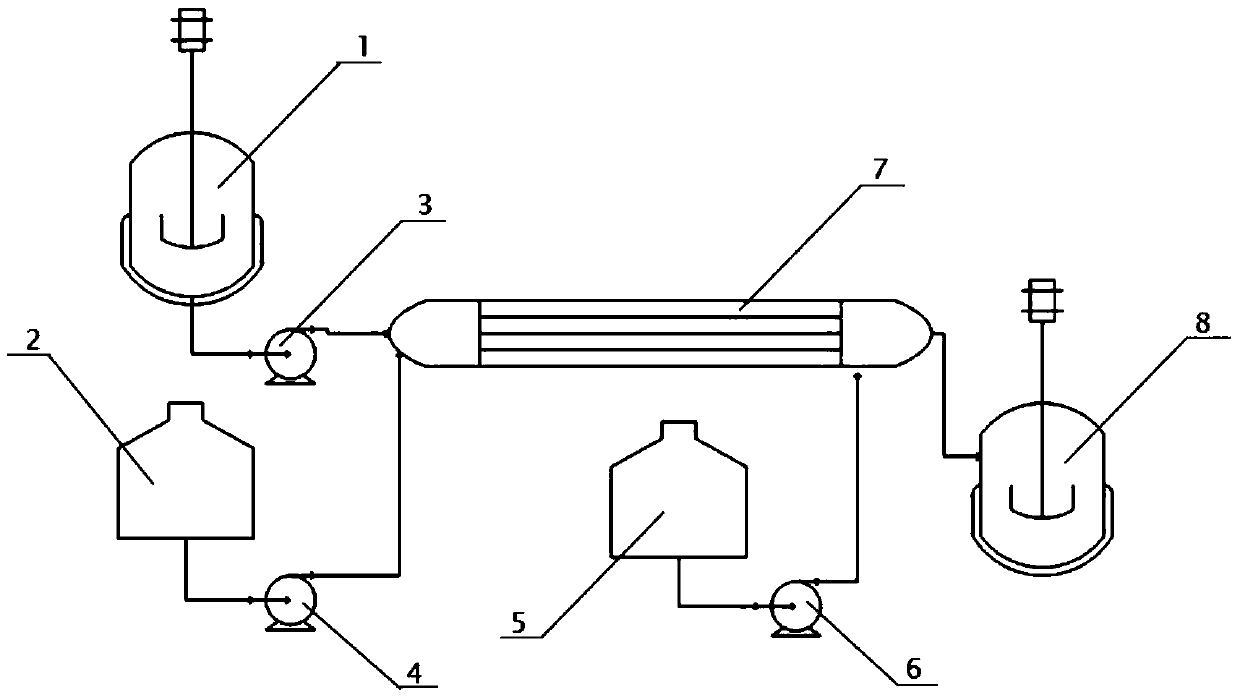

[0034] At a temperature of 35°C, add β-methylnaphthalene, an emulsifier and water into the β-methylnaphthalene emulsion storage tank 1 to prepare a β-methylnaphthalene emulsion, wherein the obtained β-methylnaphthalene emulsion contains β - the massfraction of methylnaphthalene is 16%, adds oxidation solution in the storage tank of oxidation solution, 300g / L of red alum sodium concentration in the oxidation solution, acid value is that the concentration of acid is 500g / L with sulfuric acid, and β-methylnaphthalene The emulsion and the oxidation liquid pass through the first metering pump 3 and the second metering pump 4 respectively and are measured according to the volume ratio of β-methylnaphthalene emulsion: oxidation liquid at a ratio of 1:2.3, and then enter the tubular reactor 7 with an ultrasonic device To carry out the reaction, the reaction temperature is controlled at 45-55°C by a constant temperature water bath device, and the residence time in the tubular reactor is...

Embodiment 2

[0036] At a temperature of 35°C, add β-methylnaphthalene, an emulsifier and water into the β-methylnaphthalene emulsion storage tank 1 to prepare a β-methylnaphthalene emulsion, wherein the obtained β-methylnaphthalene emulsion contains β - the massfraction of methylnaphthalene is 18%, adds oxidation solution in the storage tank of oxidation solution, 300g / L of red alum sodium concentration in the oxidation solution, acid value is that the concentration of acid is 500g / L with sulfuric acid, and β-methylnaphthalene The emulsion and the oxidizing liquid pass through the first metering pump 3 and the second metering pump 4 respectively and are measured according to the volume ratio of β-methylnaphthalene emulsion: oxidizing liquid at a ratio of 1:2.0, and then enter the tubular reactor 7 with an ultrasonic device To carry out the reaction, the reaction temperature is controlled at 40-60°C by a constant temperature water bath device, and the residence time in the tubular reactor is...

Embodiment 3

[0038]At a temperature of 35°C, add β-methylnaphthalene, an emulsifier and water into the β-methylnaphthalene emulsion storage tank 1 to prepare a β-methylnaphthalene emulsion, wherein the obtained β-methylnaphthalene emulsion contains β - the massfraction of methylnaphthalene is 16%, adds oxidation solution in the storage tank of oxidation solution, 350g / L of red alum sodium concentration in the oxidation solution, acid value is that the concentration of acid is 550g / L with sulfuric acid, and β-methylnaphthalene The emulsion and the oxidizing liquid pass through the first metering pump 3 and the second metering pump 4 respectively and are measured according to the volume ratio of β-methylnaphthalene emulsion: oxidizing liquid at a ratio of 1:2.5, and then enter the tubular reactor 7 with an ultrasonic device To carry out the reaction, the reaction temperature is controlled at 48-52°C by a constant temperature water bath device, and the residence time in the tubular reactor is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com