Intelligent manufacturing system and method based on data analysis

A technology of intelligent manufacturing and data analysis, applied in manufacturing computing systems, general control systems, control/regulation systems, etc., can solve problems such as unreasonable overall design, inconvenient use, inability to realize intelligent real-time monitoring and control, etc. Realize automatic control, reduce workload, and achieve the effect of big data analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

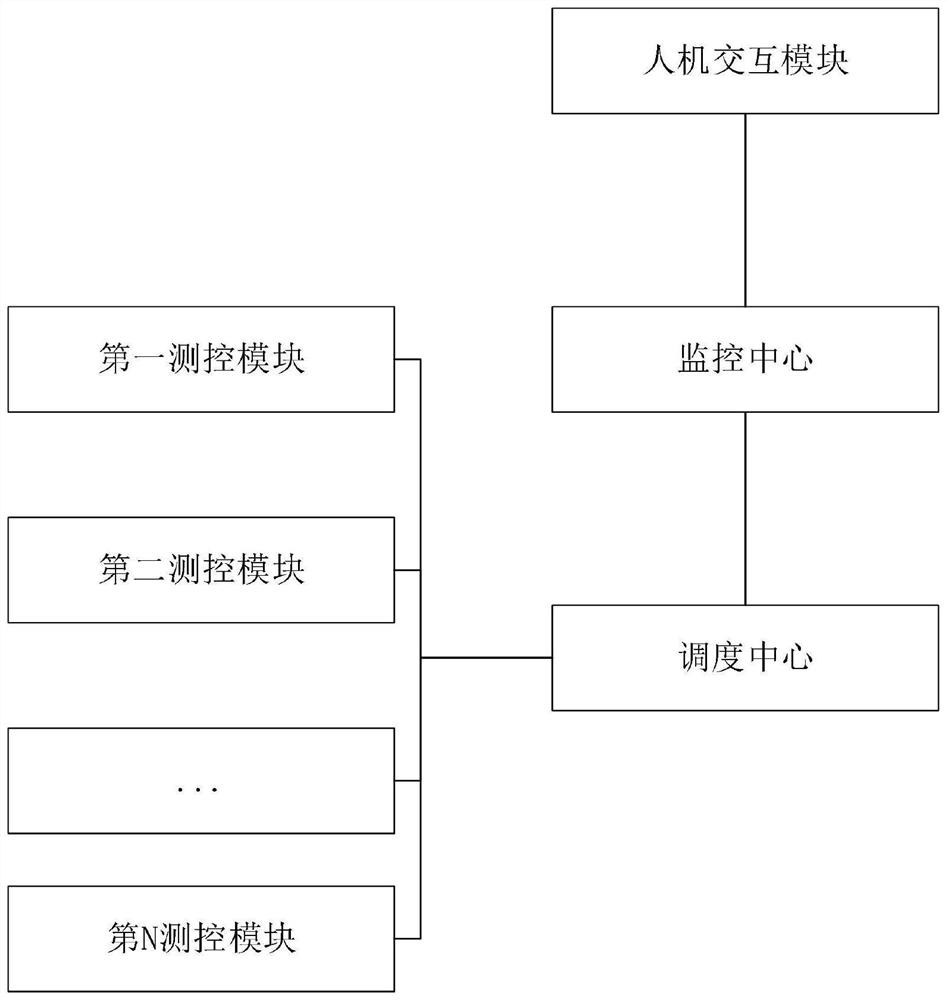

[0020] Such as figure 1 As shown, an intelligent manufacturing system based on data analysis includes: a human-computer interaction module and a plurality of measurement and control modules. equipment; he also includes a dispatch center.

[0021] Further, the human-computer interaction module includes a host computer, an alarm, a display screen and a control panel, and the host computer is provided with a first controller, a data storage unit and a data analysis unit; the first controller uses To receive the industrial equipment operation data sent by the measurement and control module, and send control instructions to the measurement and control module; the data storage unit is used to store the operation data; the data analysis unit is used to analyze the operation data Carry out analysis and processing and judge the operating status of industrial equipment and whether to send control instructions according to the processing results; the alarm is used to give an alarm when ...

Embodiment 2

[0024] Embodiment 2: a kind of office automation control method, described method comprises: build the big data analysis platform that comprises sensor network data, controller data and manufacturing information system data based on Hadoop distributed platform; Use Apriori association rule under MapReduce framework The mining algorithm mines the constraint factors of planning and scheduling, and obtains the process sequence constraints, resource constraints, temporary process constraints and planning time constraints of the corresponding planning projects; according to the mining planning and scheduling constraints, the planning project cycle and The processing cycle of each process in the planned project and the start and finish time of the process are obtained, and finally the start and finish time of the planned project are obtained, and the planned project is scheduled according to the start and finish time.

[0025]Further, when mining the constraint factors, the specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com