Photovoltaic solder strip and photovoltaic module

A technology of photovoltaic ribbons and ribbons, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as low uniformity and stability of coating thickness, reduced long-term reliability of components, and virtual soldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these examples.

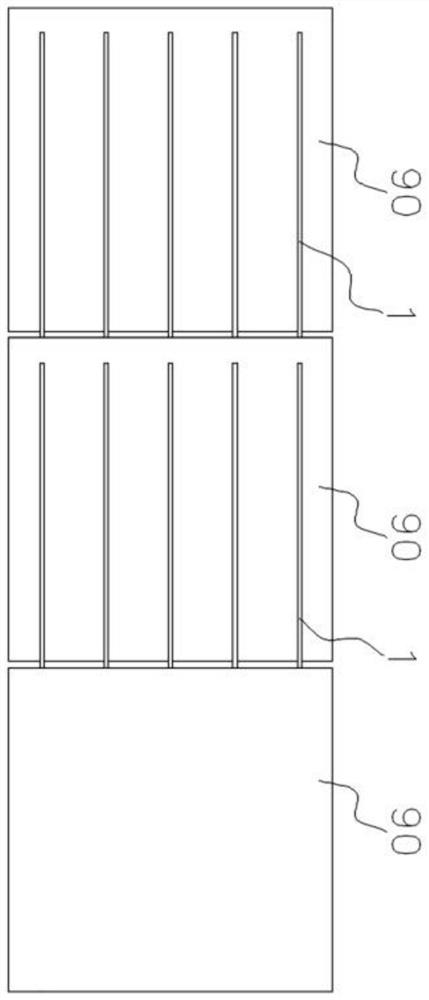

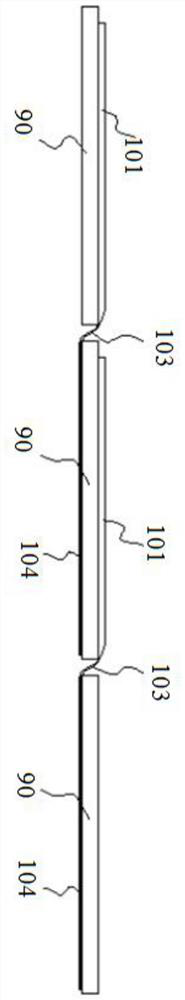

[0029] The technical solution of the present invention provides a photovoltaic ribbon, which includes a substrate and a coating coated on the outer surface of the substrate. The photovoltaic ribbon is a periodic ribbon section, and a single periodic ribbon section includes: the first Segments for bonding on front grid wires of photovoltaic cells, wherein the base of the first segment has a square cross-section or a square cross-section with rounded corners; and a second segment for connection and bonding adjacent photovoltaic cells.

[0030] By adopting a ribbon substrate with a square or rounded square cross section, the cross-sectional area of the conductive substrate is increased without changing the width (or diameter) and thickness of the ribbon, and the resistance is reduced. Shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com