Pipe fitting cutting equipment and horseshoe cutting method thereof

A technology for cutting equipment and pipe fittings, used in metal processing equipment, other manufacturing equipment/tools, metal processing machinery parts, etc., can solve the problems of low end face accuracy, manual control, rocket duct fracture, etc., and achieve high positioning accuracy and cutting processing. Accuracy, convenience, fast and accurate positioning, reliable and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

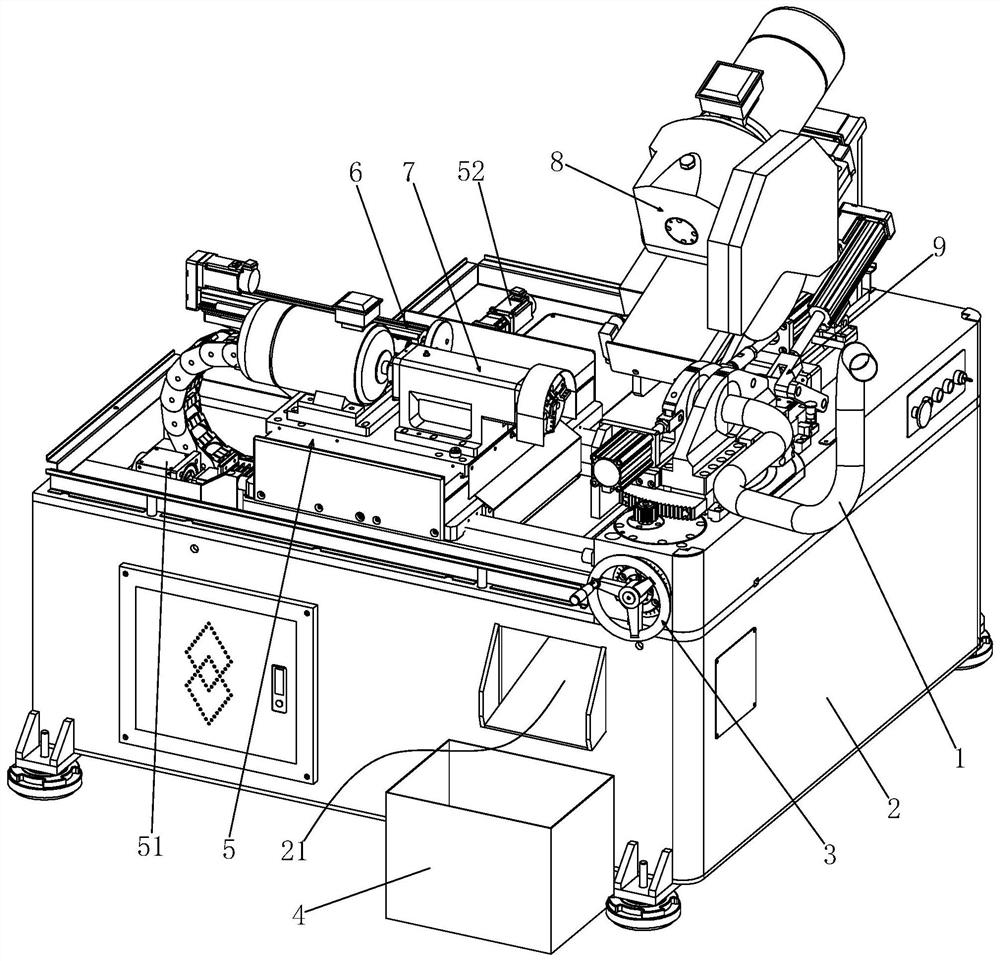

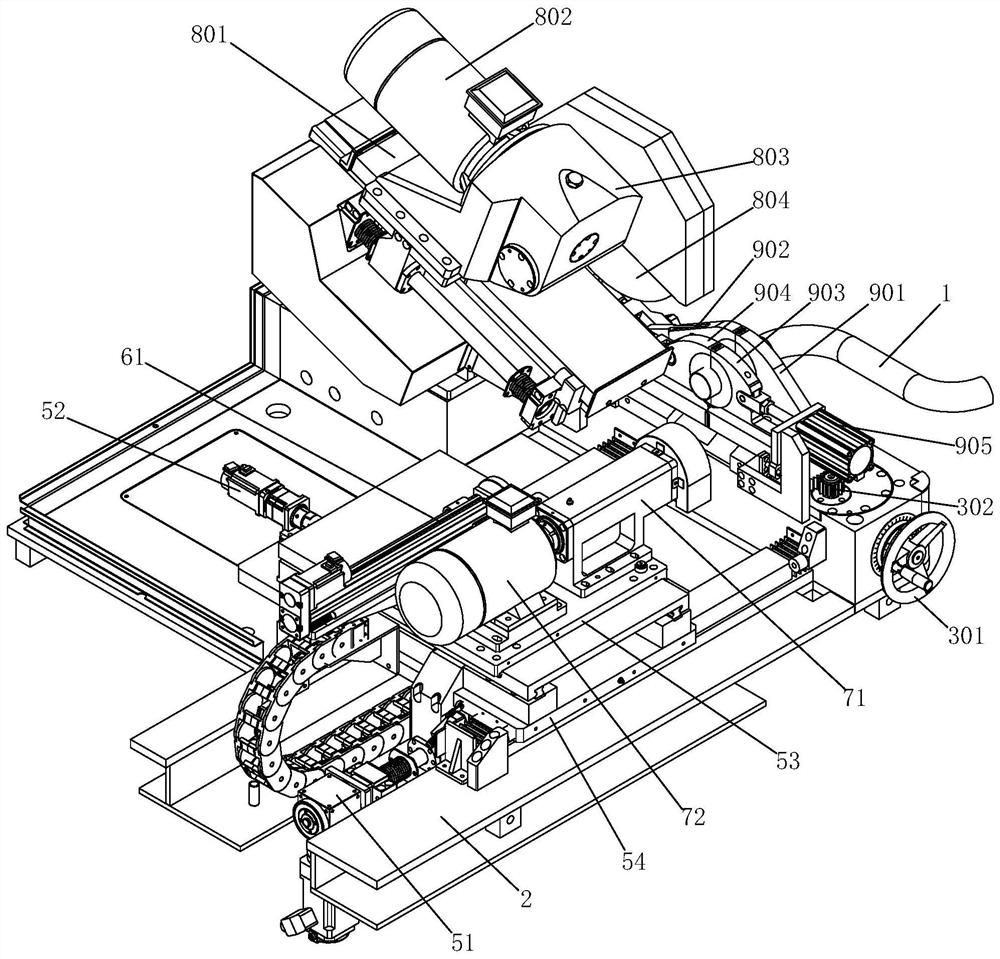

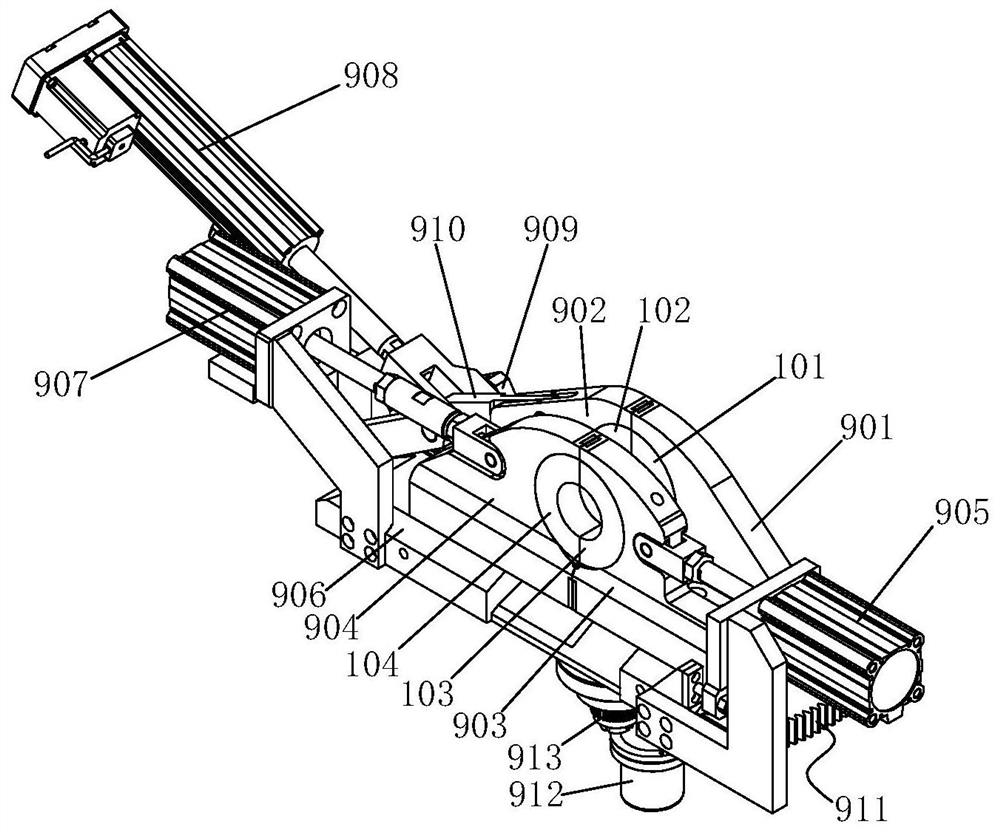

[0048] Such as figure 1 and figure 2 Shown is a conduit margin cutting device, which is used for margin cutting and flat processing of engine conduits in the aerospace field, and includes a fuselage 2 on which an angle adjustment device 3, a cutting device 8, and a conduit clamp are installed Holding device 9 and carriage mechanism 5, positioning device 6 and flat opening device 7 are installed on the carriage mechanism 5, positioning device 6 and flat opening device 7 are set one after the other, carriage mechanism 5 and conduit clamping device 9 one left one Set on the right, the fuselage 2 is also provided with a waste chute 21, the waste chute 21 is located between the carriage mechanism 5 and the conduit clamping device 9, the cutting device 8 feeds forward and backward, and the outlet of the waste chute 21 is set for collecting waste waste bin 4.

[0049] This equipment adopts digital control, the digital controller includes PLC controller, the PLC controller is set i...

Embodiment 2

[0089] A pipe fitting cutting device, comprising a fuselage 2, on which an angle adjustment device 3, a cutting device 8, a conduit clamping device 9 and a carriage mechanism 5 are installed, and a positioning device 6 is installed on the carriage mechanism 5, and the positioning device 6 and the conduit clamping device 9 are arranged opposite to each other on the left and right, and the cutting device 8 feeds forward and backward. The only difference from Example 1 is that there is no flat opening device 7, and only the catheter cutting function is implemented. The location arrangement, specific structure and various implementation modes of each device are the same as those in Example 1.

[0090] The cutting method of the above-mentioned pipe cutting equipment includes the following steps:

[0091] 1) The positioning driver 61 and / or the feed motor 51 drive the positioning block 64 to a designated position according to the positioning parameters of the catheter 1 to be cut; ...

Embodiment 3

[0101] A kind of equipment for flat opening of pipe fittings, comprising a fuselage 2, an angle adjustment device 3, a conduit clamping device 9, and a carriage mechanism 5 are installed on the fuselage 2, a positioning device 6 and a flat opening device 7 are installed on the carriage mechanism 5, and the positioning device 6 and the conduit clamping device 9 are oppositely arranged left and right, and the flat opening device 7 moves left and right to feed the knife. The only difference from Example 1 is that the cutting device 8 is not provided, and only the end face of the catheter nozzle is flat-mouthed.

[0102] The flat mouth processing method of the above-mentioned pipe fitting flat mouth equipment includes the following steps:

[0103] 1) The positioning driver 61 and / or the feed motor 51 drive the positioning block 64 to a designated position according to the positioning parameters of the catheter 1 to be processed;

[0104] 2) The end of the catheter 1 is pressed ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com