Flow guide net punching isolating film composite material structure production system

A composite material and production system technology, which is applied in the field of composite material structure production system of diversion net perforated isolation film, can solve problems such as damage, discontinuous production work, and impact on product quality, so as to improve work efficiency and ensure continuous winding The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

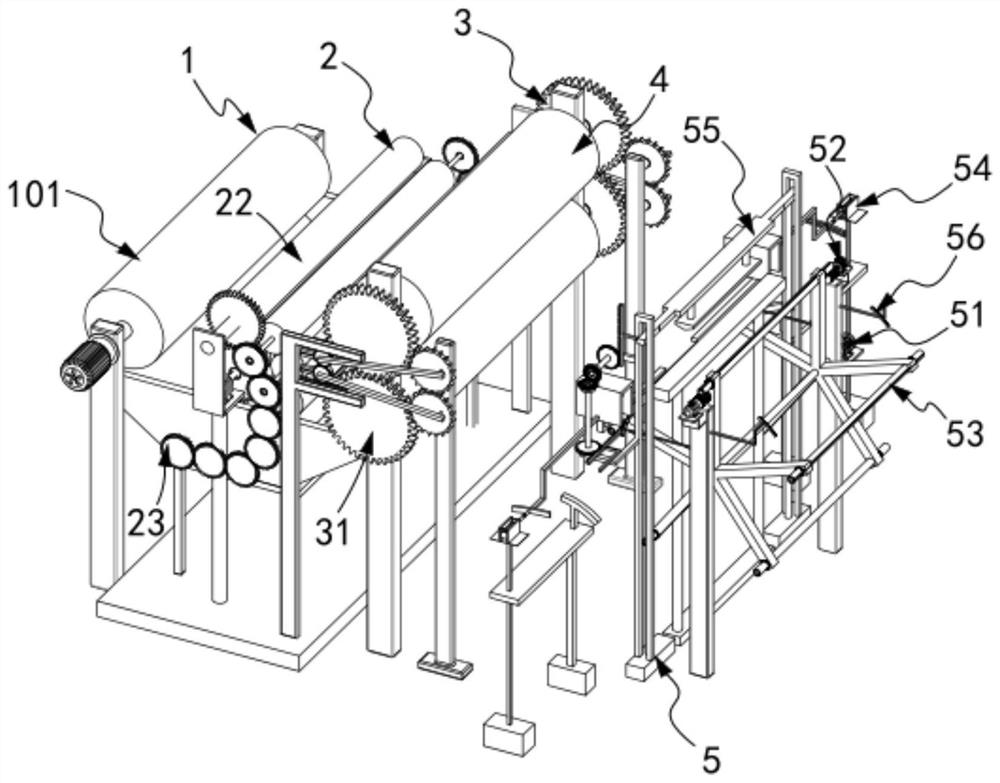

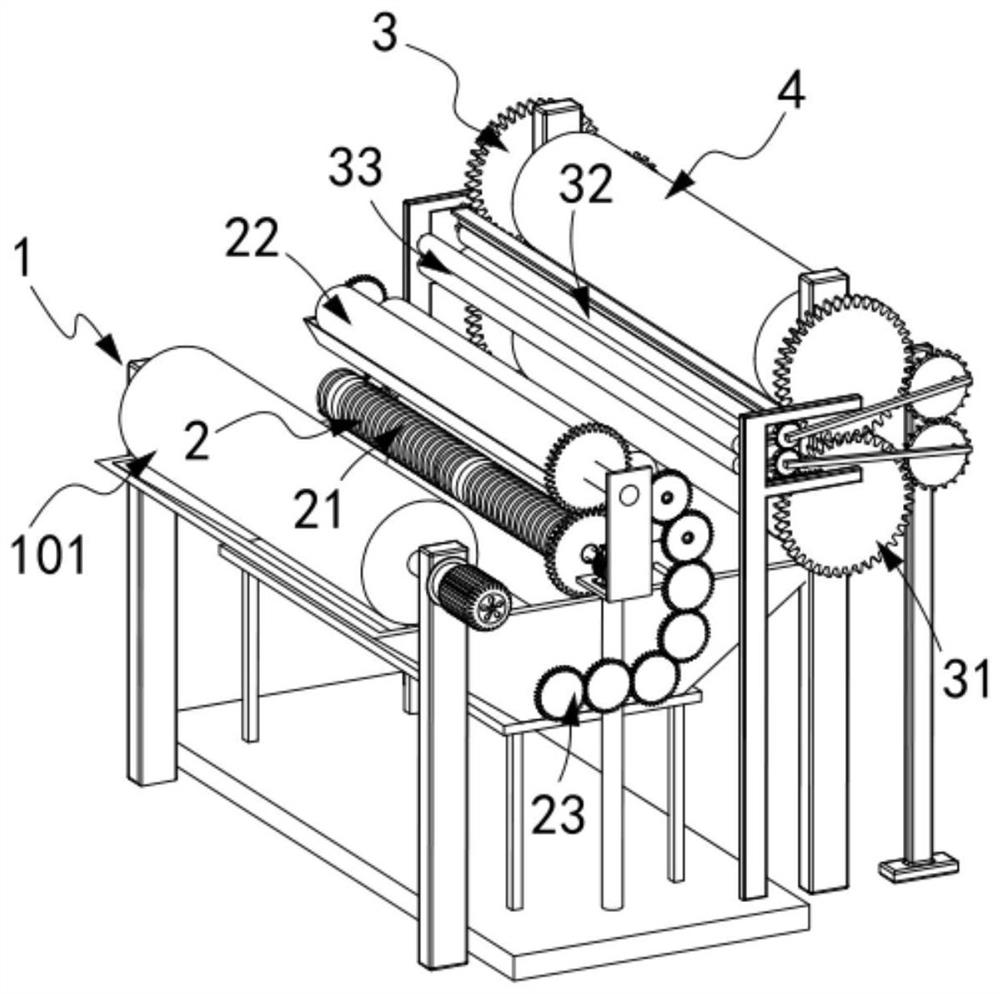

[0089] Such as Figure 1 to Figure 3 As shown, a composite material structure production system of perforated isolation membrane with diversion net, including:

[0090] A gluing mechanism 1, the gluing mechanism 1 includes a gluing mechanism 101, a first gluing mechanism 2 and a second gluing mechanism 3 arranged along the conveying direction of the composite guide net 30, and the second gluing mechanism 3 It includes a speed change assembly 31, a stretching assembly 32 located between the first glue leveling mechanism 2 and the speed change assembly 31, and a glue coating component 33 arranged between the stretching assembly 32 and the first glue leveling mechanism 2, so When the above-mentioned stretching assembly 32 performs composite work on the composite flow guide net 30, the glue is extruded onto the stretching assembly 32, and then the extruded glue is transferred to the glue-coating assembly 33 by the stretching assembly 32, and the glue-covering assembly of the trans...

Embodiment 2

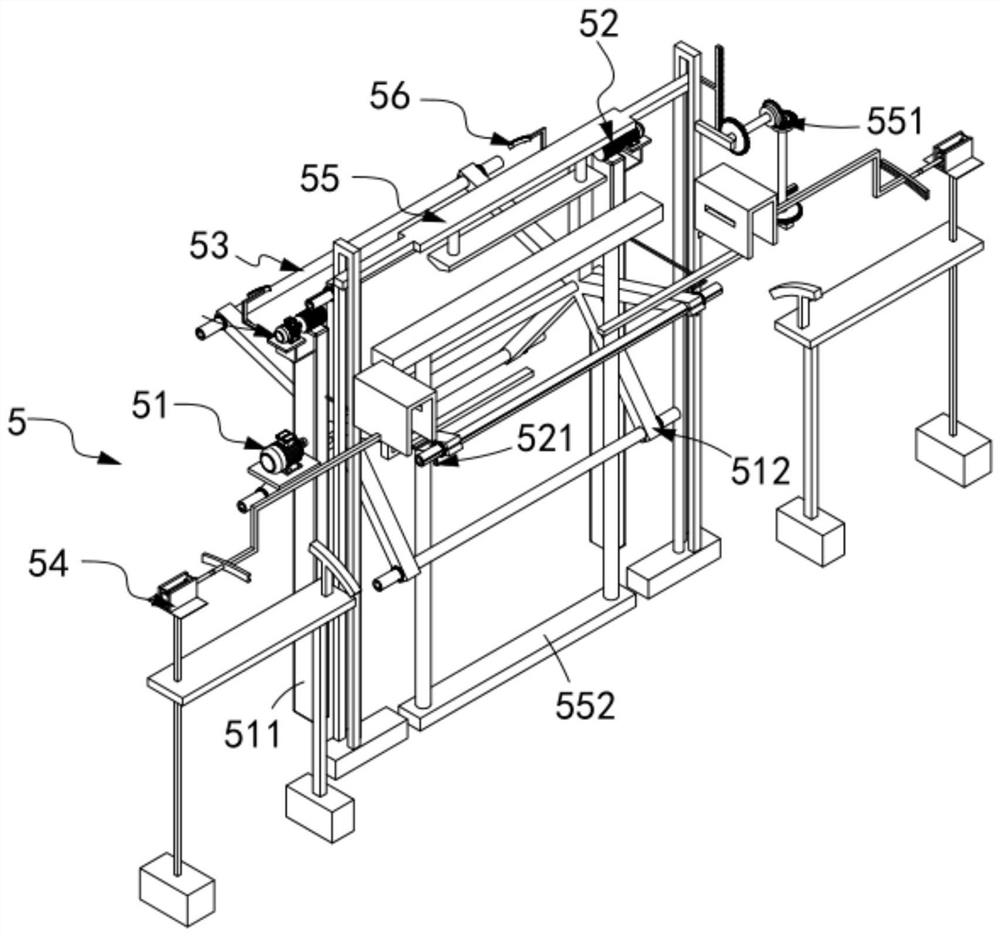

[0153] Such as Figure 23 to Figure 25 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is:

[0154] further, such as Figure 23 to Figure 25 As shown, the cutting mechanism 55 is arranged between the to-be-replaced station 1e and the winding station 1a, and it includes a transmission assembly 551 that is synchronously driven with the winding work and the driving mechanism of the transmission assembly 551 Next, the cutter assembly 552 for cutting the product,

[0155] The transmission assembly 551 includes a first drive rack 5511 fixedly connected to the telescopic end of the first flat-push cylinder 541 and provided with a one-way tooth structure, a transmission member 5512 and a second drive rack 5514,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com