Tire bead structure having high density exhaust line

An exhaust line, high-density technology, applied to the reinforcement layer of pneumatic tires, road vehicle tires, tire parts, etc., can solve the problem of increasing downward movement of circumferential parts, increasing the amount of interference fit, and not reducing heat generation and other issues to achieve better heat dissipation, high bead strength, and the effect of preventing tire grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with specific implementation below.

[0022] A bead structure with high-density venting lines. The novel tire bead structure requires a certain number of venting lines to be designed in proportion to the size of the tire product during mold design.

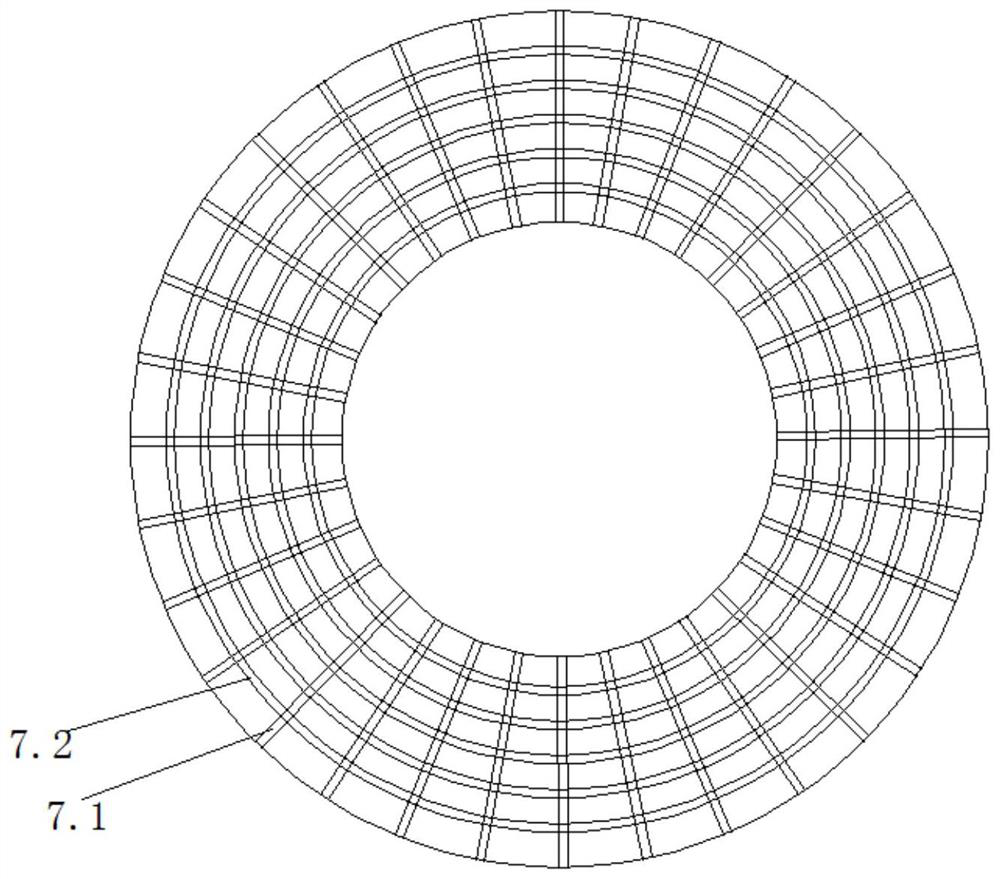

[0023] The bead structure of the new tire is a concave structure on the mold, a convex structure on the tire, and the exhaust lines are arranged in a "grid shape".

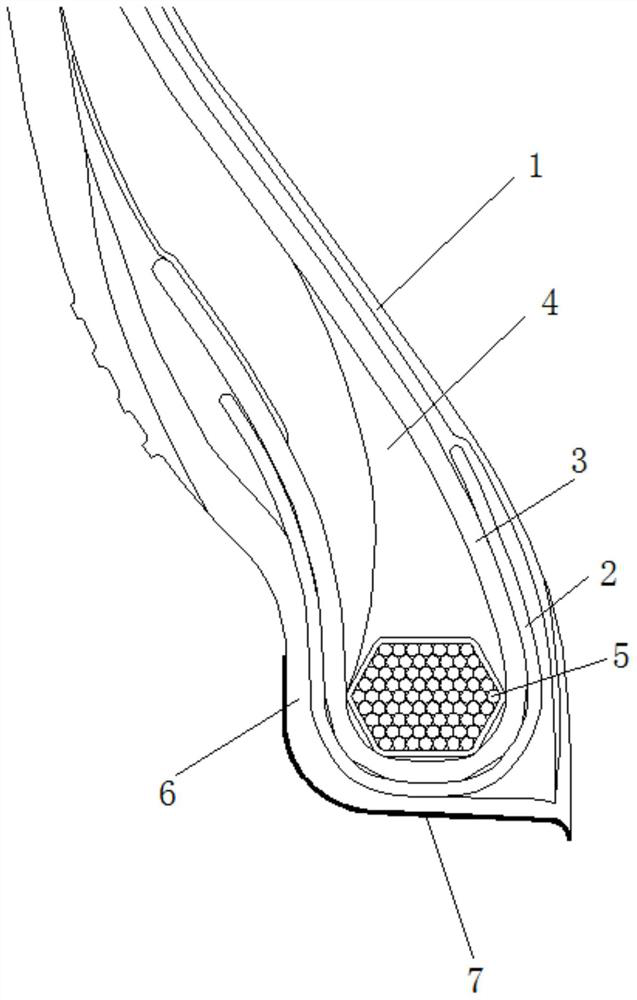

[0024] Such as Figure 1-2 As shown, this structure includes an inner lining layer 1, a steel wire hole 2, a carcass 3, a triangle body 4, a steel traveler 5, a wear-resistant colloid 6 and an exhaust line 7 distributed sequentially from the inside to the outside;

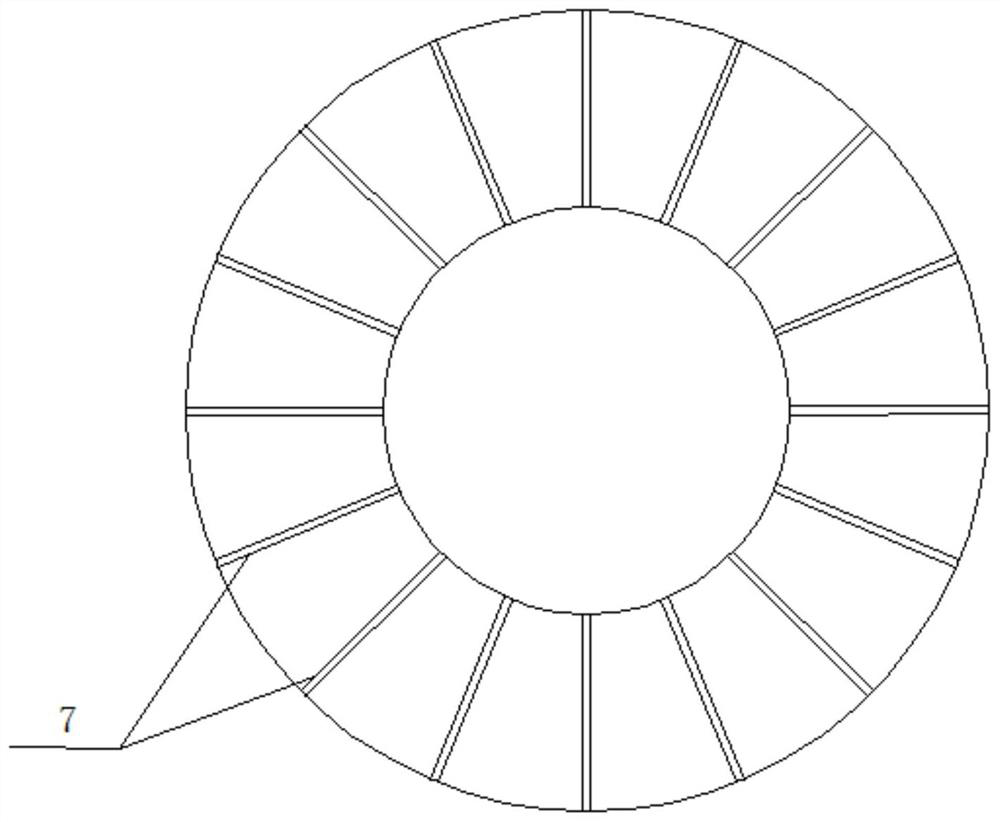

[0025] Such as image 3 As shown, the exhaust lines of the existing common tire bead are generally arranged in 16 equal parts in the circumferential direction, which is a single-line structure. After contacting with the rim, there will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com