Full-automatic taped chip programming equipment

A burning equipment, fully automatic technology, applied in lighting and heating equipment, static storage, conveyor objects, etc., can solve the problems of large space occupation, difficult processing and assembly, etc., to achieve small space occupation, low processing and assembly difficulty, The effect of high transfer efficiency and high programming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

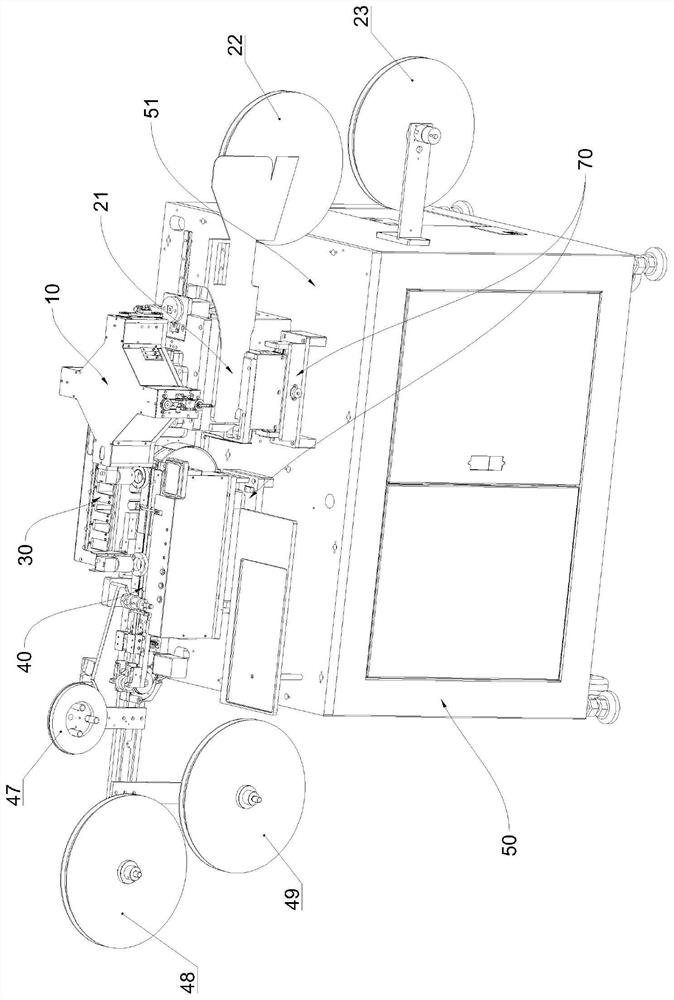

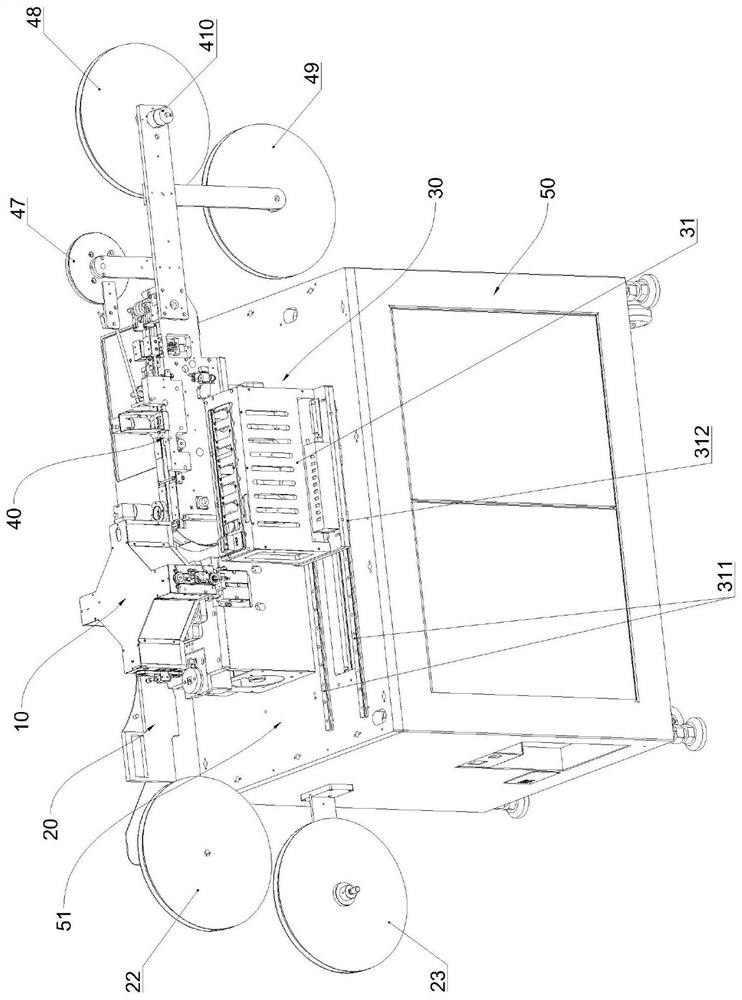

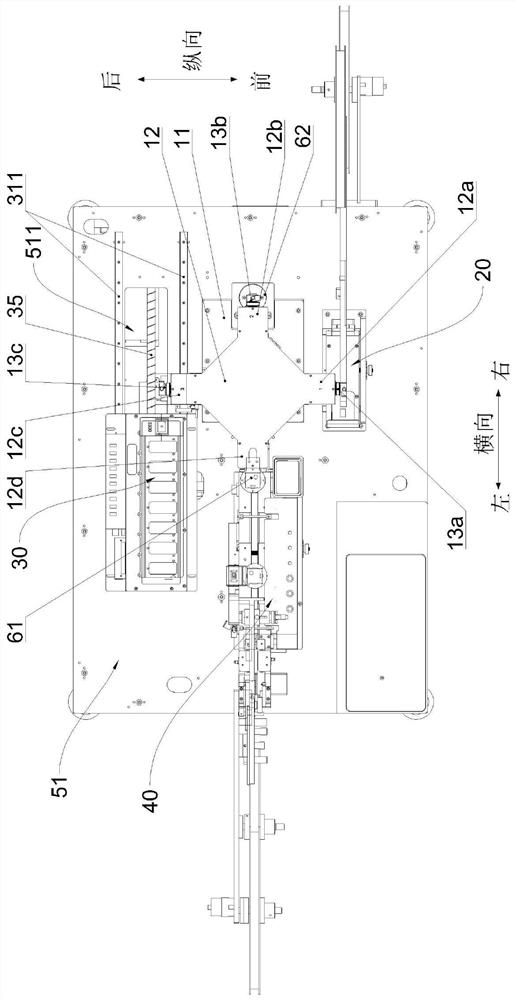

[0033] See figure 1 , figure 2 and image 3 , the automatic braiding type chip burning equipment of the present invention, it comprises working platform 51 and the braiding type chip feeding device 20 that is installed on the working platform, burning device 30, chip receiving and braiding device 40 and chip rotary conveyance Device 10, wherein burning device 30 comprises burner 32, and working platform 51 is fixedly installed on the top of equipment cabinet 50, and chip rotary conveyance device 10 comprises base 11, rotating rack 12 and chip suction mechanism, and base 11 is fixed on On the working platform 51, the longitudinal front side of the base 11 is the chip loading side, the longitudinal rear side is the chip programming side, and the horizontal left side is the chip unloading side. The outer peripheral surface of the rotating frame 12 has four protruding installation and the four installation ends are symmetrically distributed in a cross shape. The four installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com