Vacuum cooling equipment used in the production of meltblown materials

A cooling equipment and vacuuming technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of large water consumption, increased cost and energy consumption, slow cooling speed, etc., to save water resources , optimize the effect of shortening the process and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further illustrated by the following examples.

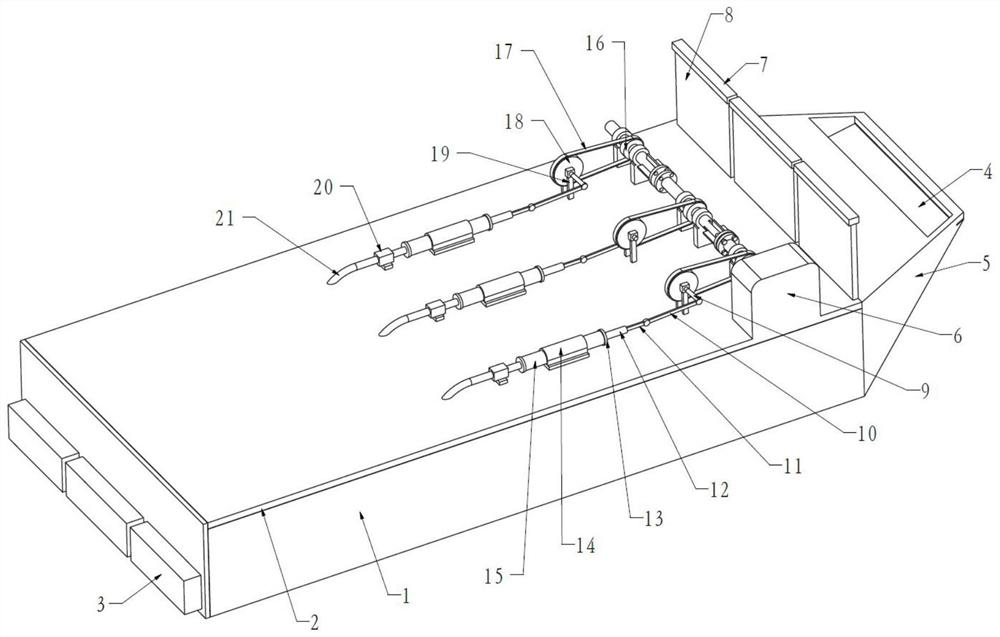

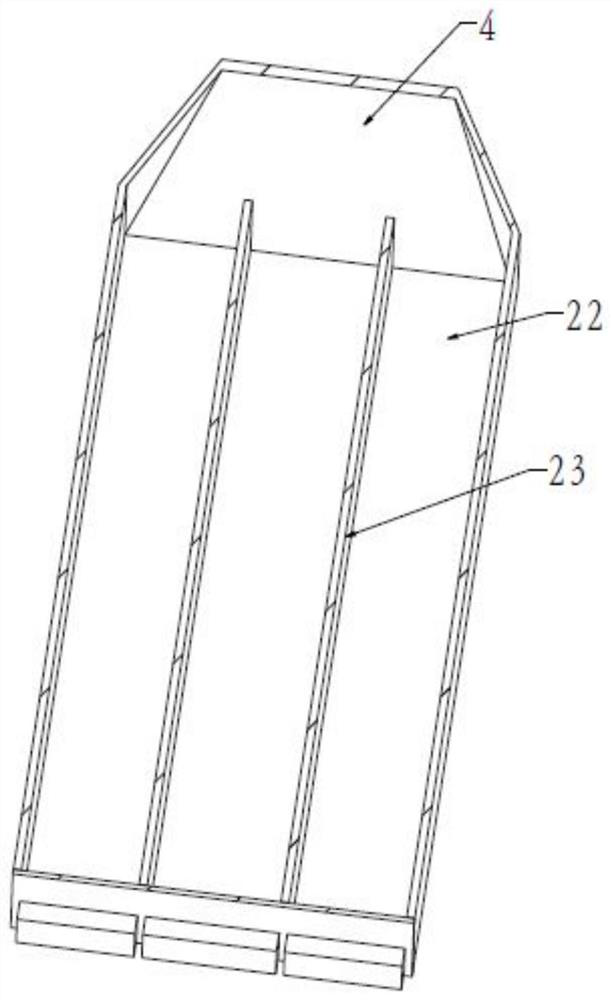

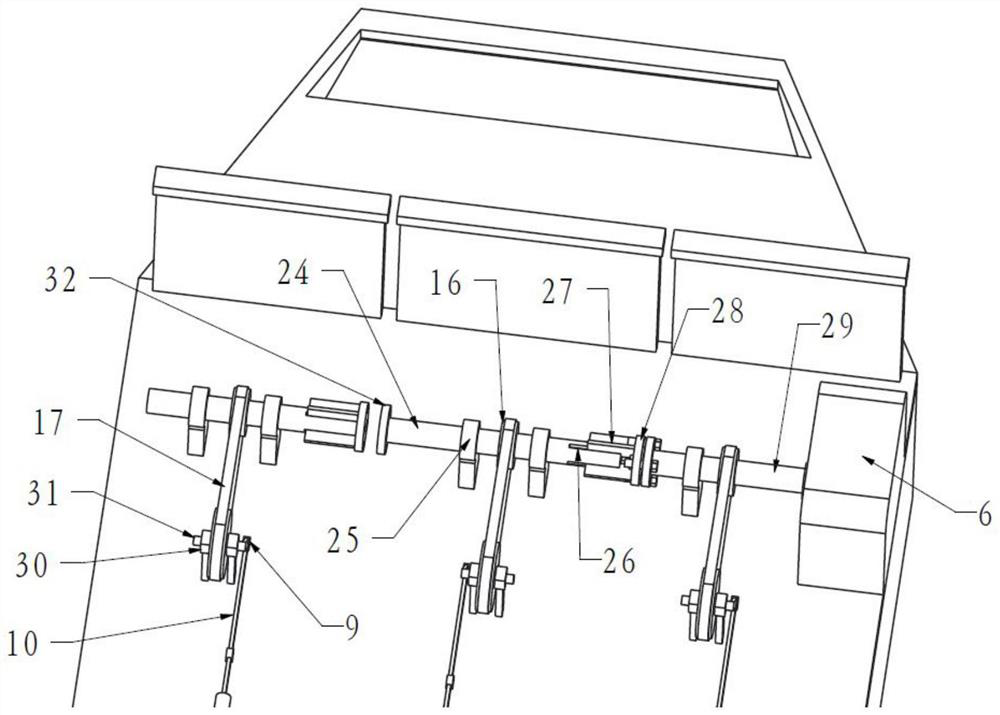

[0026] Vacuum cooling equipment applied to the production of meltblown materials, including a motor 6, the motor 6 is arranged on the cooling top cover 2 of the cooling box 1, the front part of the cooling box 1 is a cooling inlet 4, and the cooling box The rear end of the body 1 is provided with a cooling discharge valve 3, and the interior of the cooling box 1 is separated by a cooling partition 23 to form multiple cooling passages 22. An openable baffle 8 is provided in front of each cooling passage 22, and the cooling box 1 A cooling device is arranged in the base plate and the side wall; the output shaft of the motor 6 is connected with a first main shaft 29, and the rear end of the first main shaft 29 is connected with a plurality of linkage main shafts 24, and the linkage main shafts 24 can realize on-off, Both the first main shaft 29 and the interlocking main shaft 24 are supported by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com