A high-quality and high-capacity melt-blown material production equipment and process

A kind of production equipment and high-yield technology, applied in the field of high-quality and high-capacity melt-blown material production equipment and technology, can solve the problems of water consumption, low cooling efficiency, wide molecular weight distribution, etc., to save water resources, improve efficiency, and save energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further illustrated by the following examples.

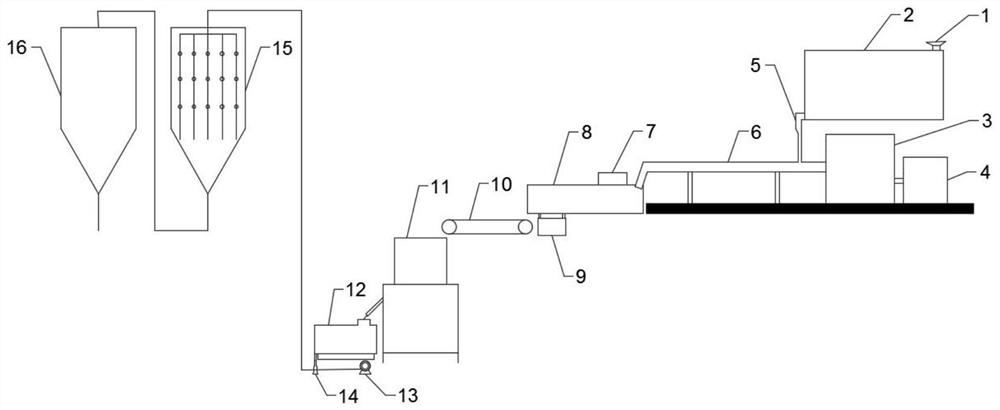

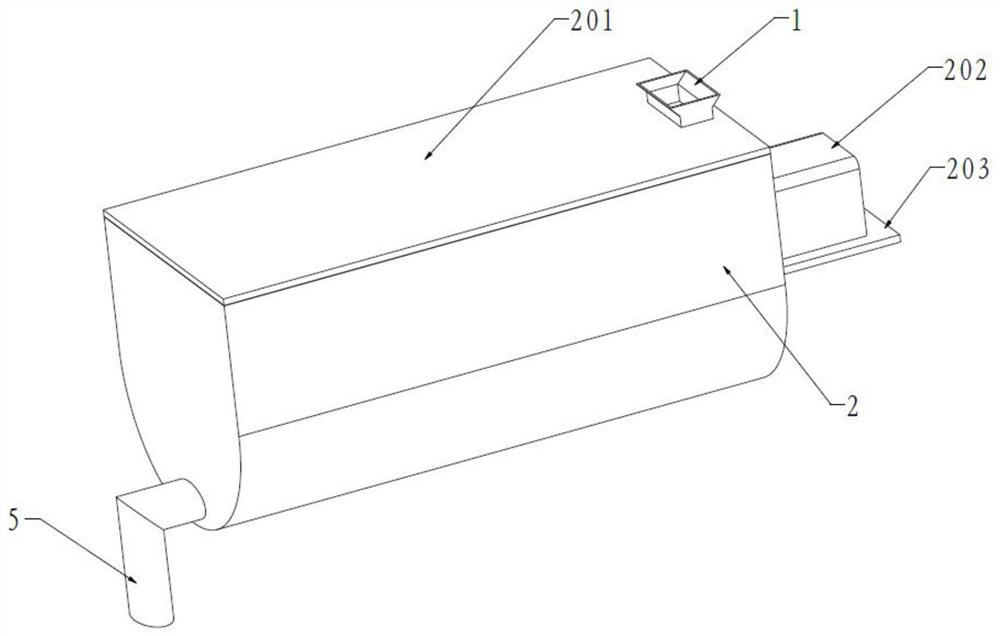

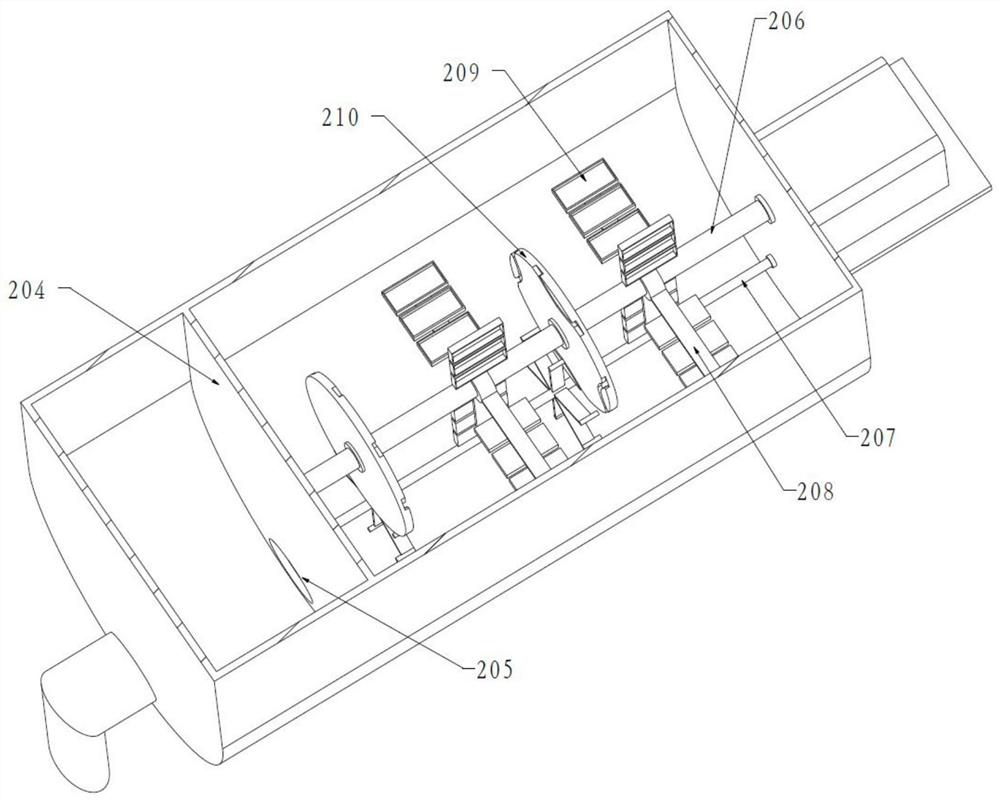

[0041] A kind of high-quality and high-capacity melt-blown material production equipment, including a mixer 2, the mixer 2 is provided with a mixing partition 204 to separate the mixer 2 into two parts before and after the space, and the front space of the mixer 2 is provided with double A layered stirring device, the stirred and mixed material enters the rear space of the mixer 2 through the first discharge hole 205 below the mixing partition 204 for short-term storage; the discharge port 5 of the rear space of the mixer 2 is connected to Twin-screw extruder 3, the twin-screw extruder 3 is connected with a transfer pump to send the degradation agent into the twin-screw extruder 3, and the extruder head 7 of the twin-screw extruder 3 is connected to the cooling device 8; The cooling device 8 includes a cooling box 801, the front part of the cooling box 801 is a cooling feed port 804, the cooling f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com