Thermal forming structure and flavone preparation equipment

A technology of thermoforming and flavonoids, which is applied in the field of thermoforming structures and flavonoids preparation equipment, can solve the problems of weak unit linkage, difficult to control product shape, complicated installation, etc., achieve uniform and controllable product shape, shorten working time, and linkage good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the drawings and embodiments.

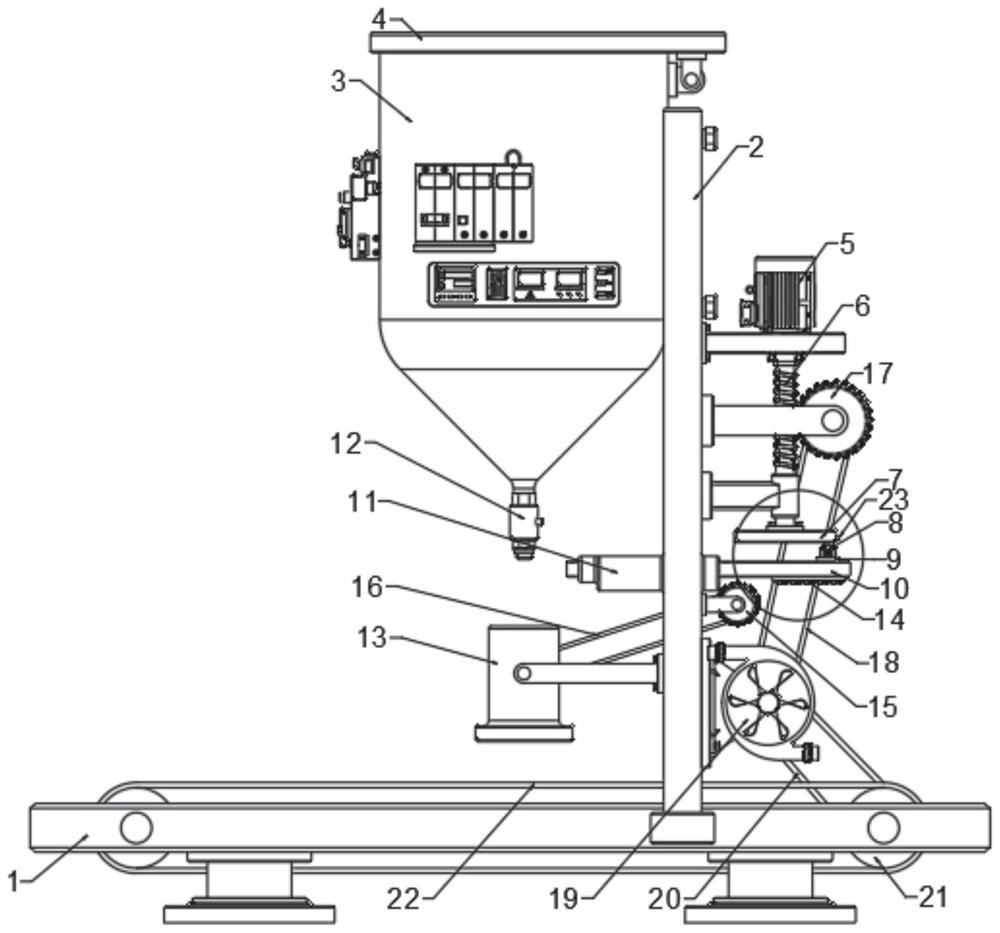

[0022] See Figure 1~4 In an embodiment of the present invention, a thermoformed structure includes:

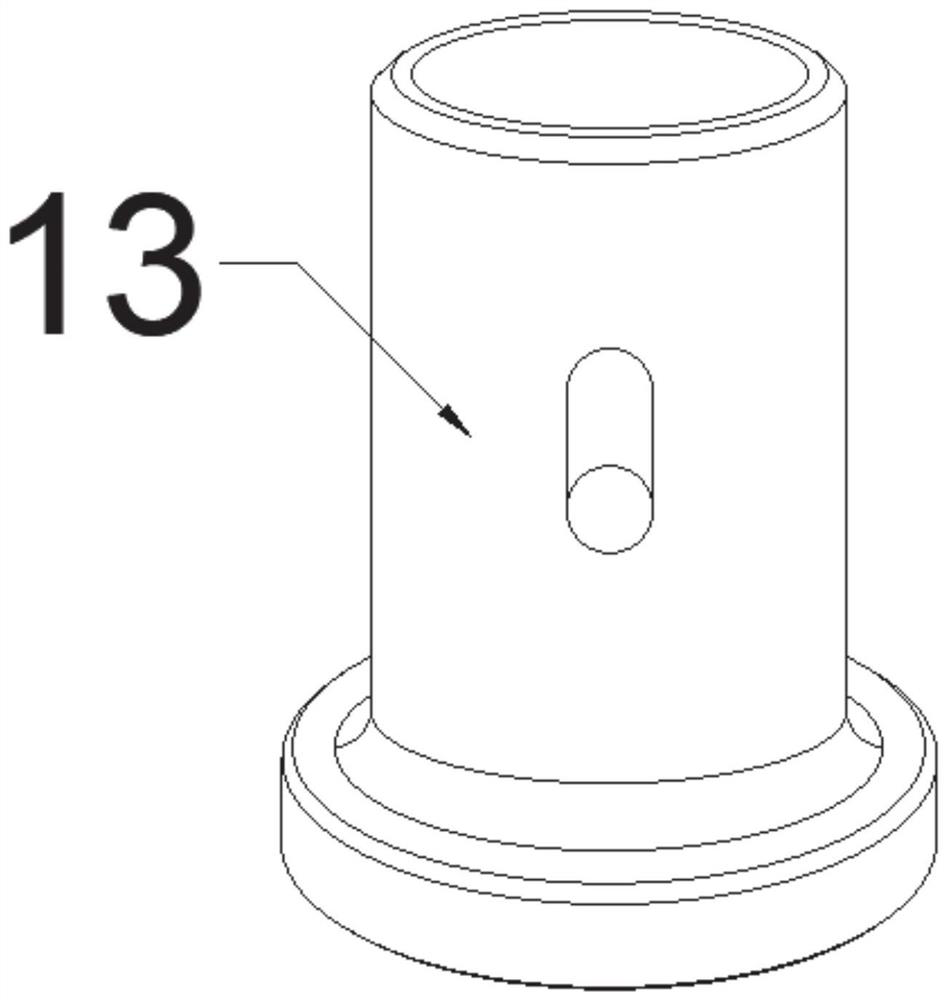

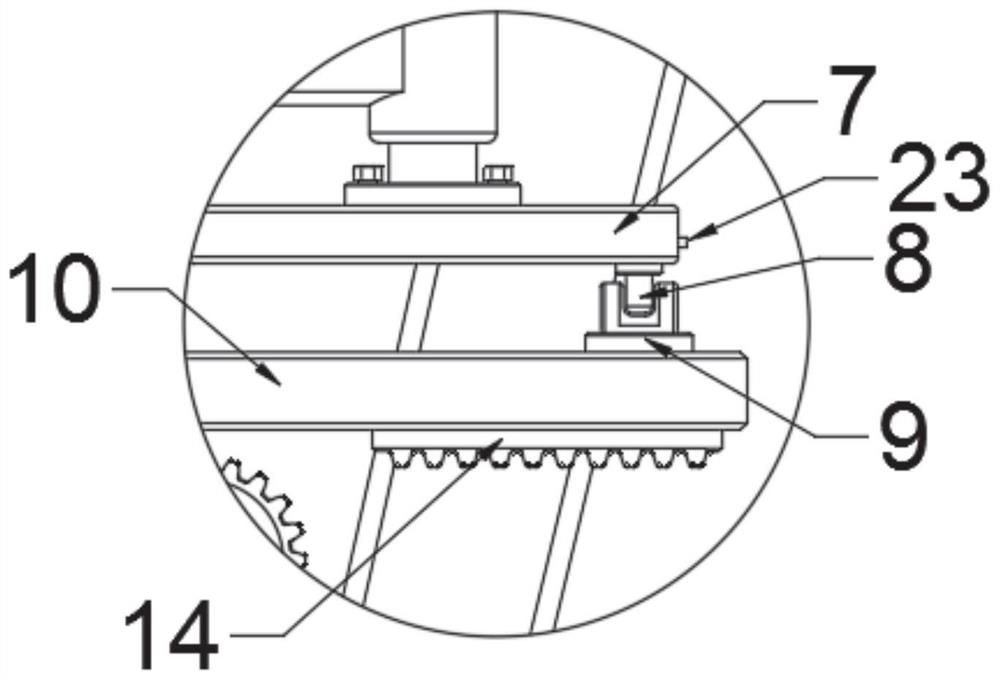

[0023] The transportation platform 1, the transportation platform 1 is arranged horizontally; the hot-melt barrel 3, the hot-melt barrel 3 is fixedly arranged above the transportation platform 1, the hot-melt barrel 3 is used to heat the flavonoid raw materials; and the feeding Assembly, the feeding assembly is arranged between the hot melt barrel 3 and the transport platform 1, and the feeding assembly is used to intermittently discharge the flavonoids hot melted into a fluid in the hot melt barrel 3; and a cooling cup 13. The cooling cup 13 is movably arranged directly under the hot melt barrel 3 by means of an overturning assembly, and the cooling cup 13 is used to receive the flavonoid fluid discharged from the hot melt barrel 3; on the hot melt barrel 3 It is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com