A high-pressure cooling fan for high-flow and low-noise fuel cell vehicles

A fuel cell and cooling fan technology, applied in battery/fuel cell control devices, electric vehicles, liquid fuel engines, etc., can solve problems such as noise increase and difficulty in achieving balance, and achieve noise reduction, simple structure, and elimination of blade tip clearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

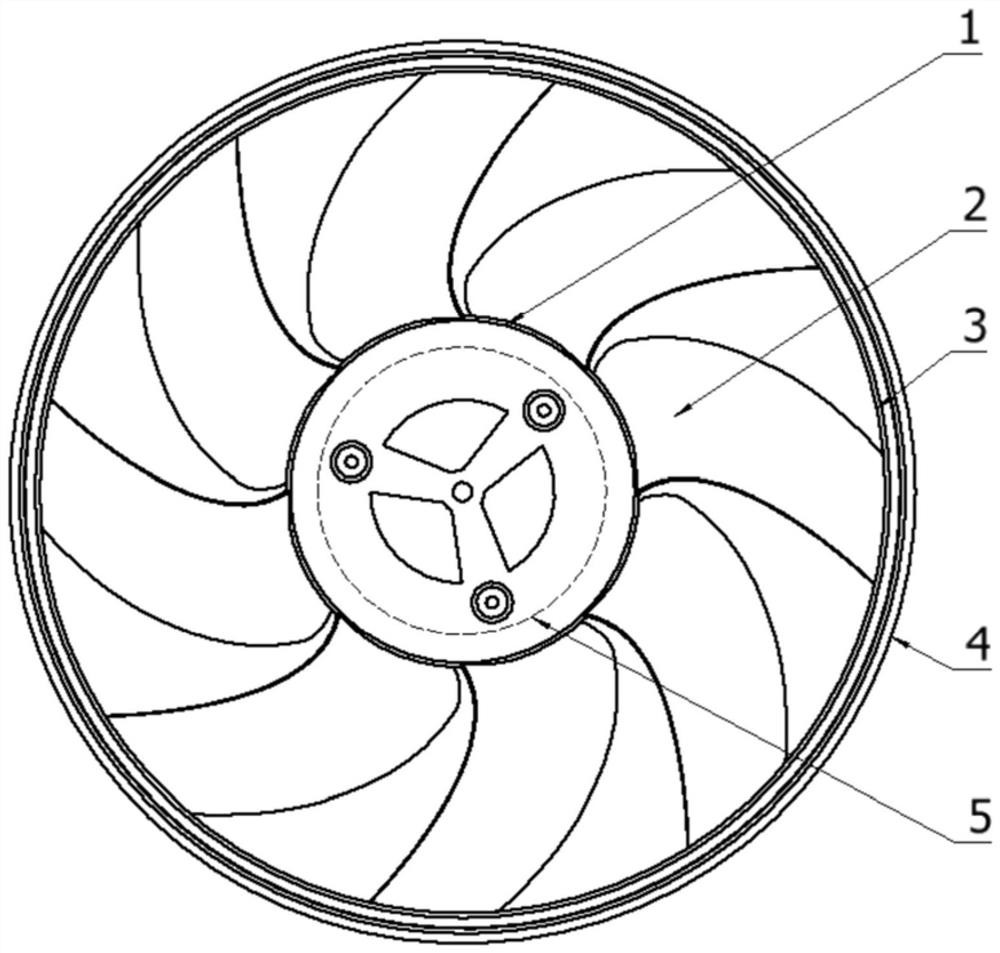

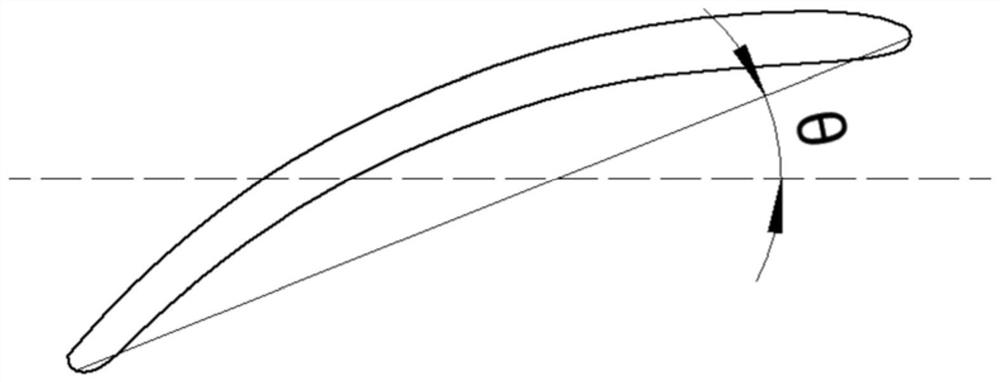

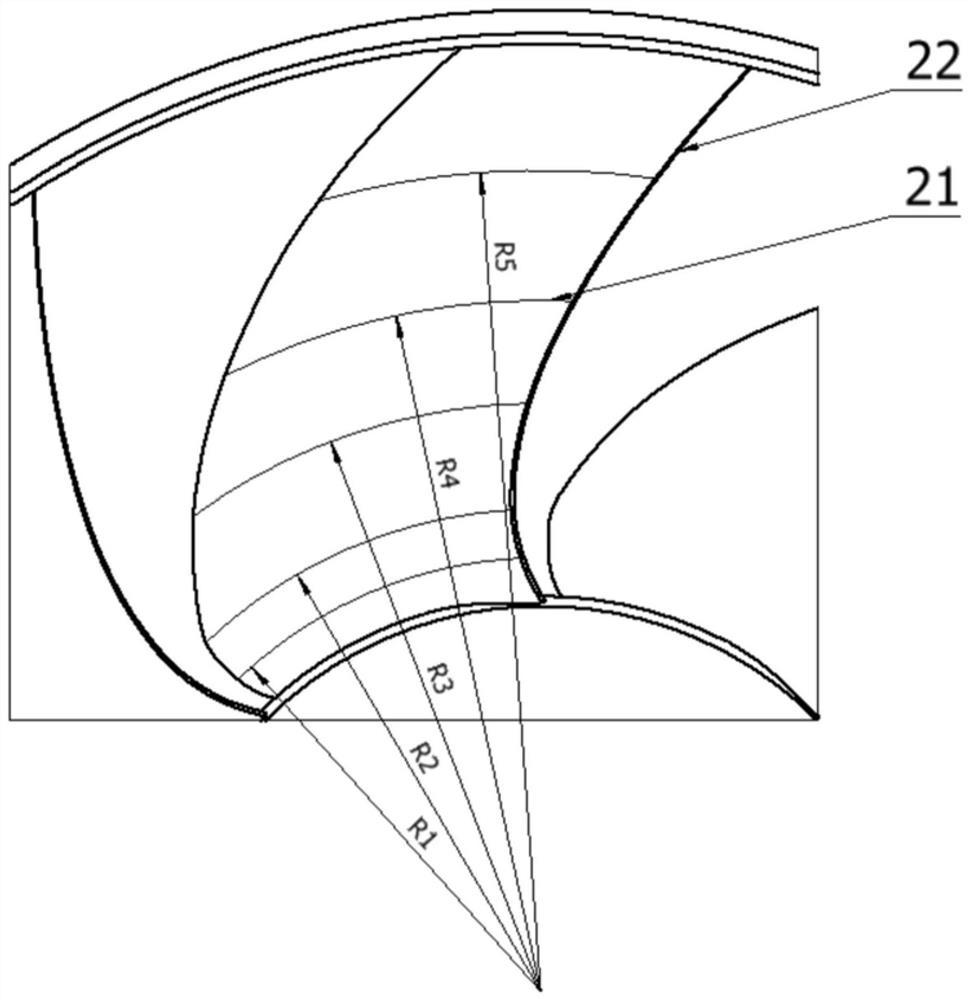

[0030] Such as figure 1 As shown, a high-pressure cooling fan for a high-flow low-noise fuel cell vehicle includes a hub 1, fan blades 2, outer ring 3 and wind protection ring 4, the hub 1 and outer ring 3 are coaxially arranged, and the fan blades 2 are fixed on the hub 1 Between the outer ring 3 and the rotation axis as the center, they are distributed at equal intervals in the circumferential direction. The number of fan blades 2 is 7-10 pieces. 5 controls rotation. The fan blade 2 includes multiple two-dimensional blade shapes. The two-dimensional blade shape is inclined at a certain blade installation angle. The two-dimensional blade shape is projected onto the corresponding circumferential cylindrical section to become a three-dimensional blade shape. The airfoil is superimposed to the inner side of the outer ring 3 along the set leading edge stacking line 22, and the installation angle of each two-dimensional airfoil is in a polynomial function relationship with the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com