A kind of device and method for producing specific fingerprint spectrum prilacol

A fingerprint and pliol technology, which is applied in the field of devices for producing specific fingerprint pliol, can solve problems such as insufficient production efficiency, extended rectification time, and inability to realize feeding and discharging, so as to improve production efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

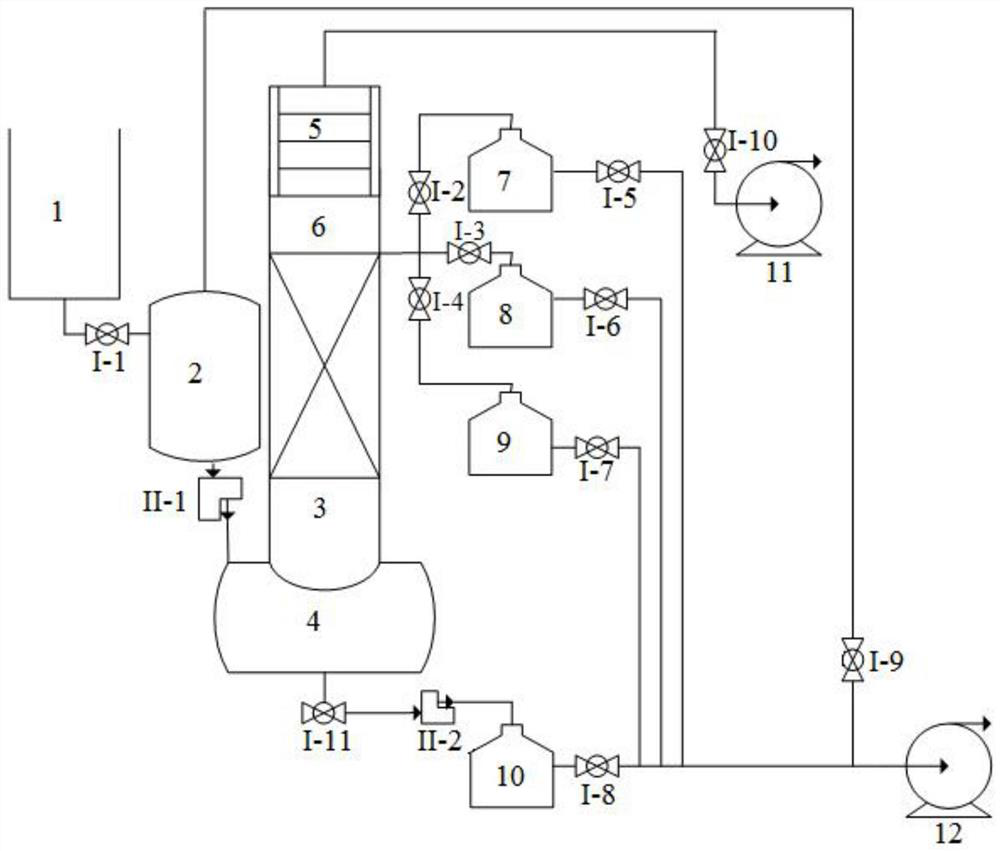

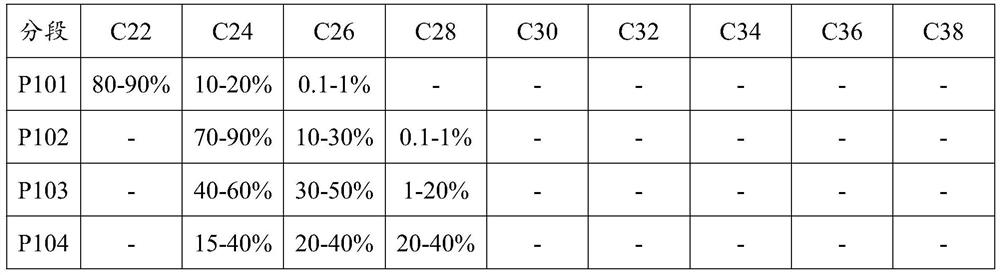

[0064] (1) A certain amount of rice bran wax is saponified into crude alcohol (fingerprint is 0.1-0.3% docosanol, 4-14% tetracosanol, 5-14% hexacosanol, 11-17% Stearyl alcohol, 17-23% triacontanol, 10-20% tricosanol, 12-20% tetracosanol, 10-14% triacetyl alcohol, 1-3% thirty octacanol) into the feed tank 1, put it into the feed tank 2 after heating the feed, then use the first delivery pump II-1 to accurately drive 18 kg into the rectifying still 4, and carry out the first batch of refining Distillation, the vacuum degree is 20-50Pa, the rectification kettle temperature is 230-250°C, and the reflux ratio is 1:5-20. Fractions are recorded as P101~P118 successively); P101 is collected in the first receiving tank 7, P102 is collected in the second receiving tank 8, and P103 is collected with the third receiving tank 9, while collecting P103, close the second valve I -2 and the third valve I-3, release P101 and P102 after the first receiving tank 7 and the second receiving tank 8...

Embodiment 2

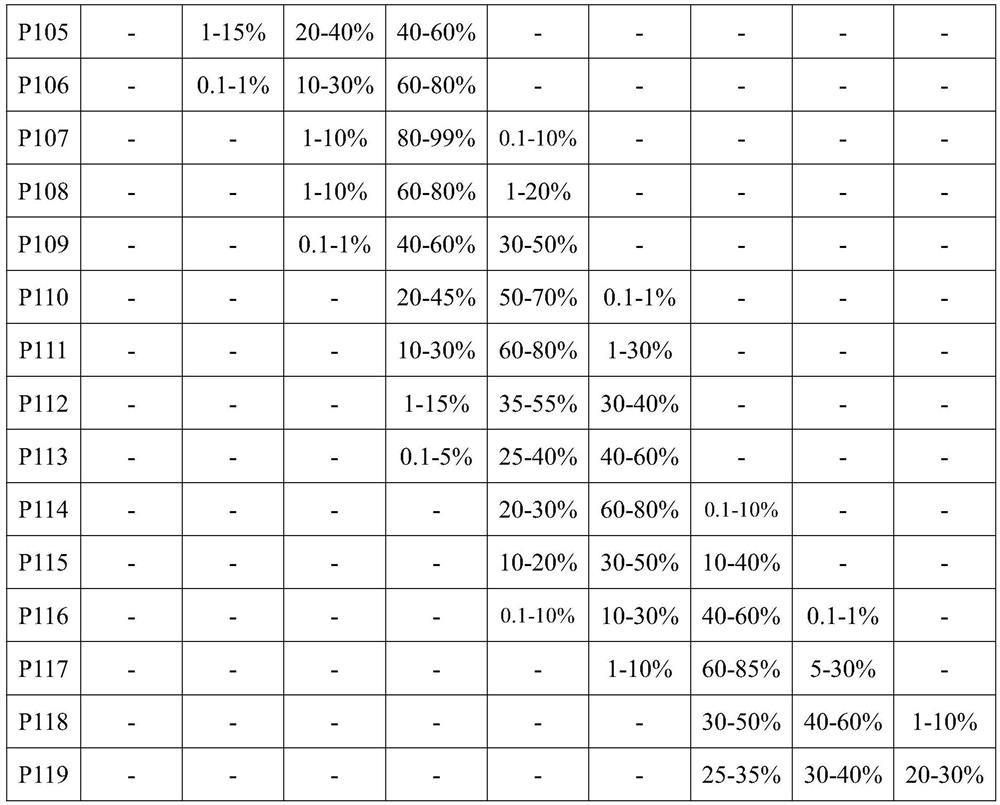

[0073] Other operating conditions are consistent with Example 1, only rice bran wax saponification crude alcohol is replaced with beeswax saponification crude alcohol (0.5~7% eicosanol, 2~10% docosanol, 10~20% tetracosane Alcohol, 1~14% hexacosanol, 10~15% octacosanol, 35~70% triacontanol, 4~22% tricosanol, 0.1~1% tetracosanol ), carry out 10 batches of rectifying altogether, the cut that collects is carried out gas chromatographic detection, analyze each batch of cut and the component content of still residue, gained result is as shown in table 2:

[0074] Table 2 The component content of each batch of fractions P101~P118 and still residue P119

[0075] section C20 C22 C24 C26 C28 C30 C32 C34 P101 60-90% 10-20% 0.1-1% - - - - - P102 0.1-1% 70-90% 1-15% 0.1-1% - - - - P103 - 40-60% 20-35% 0.5-15% 0.1-1% - - - P104 - 25-45% 30-50% 20-35% 1-15% - - - P105 - 10-30% 45-60% 30-40% 10-30% - - - P106 -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com