Preparation method and application of benzene series visual detection test paper

A technology for detecting test paper and benzene series, which is applied in the preparation and application of sensor materials, can solve the problems of poor selectivity, high cost, complicated operation, etc., and achieve the effects of reduced detection cost, convenient portability and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

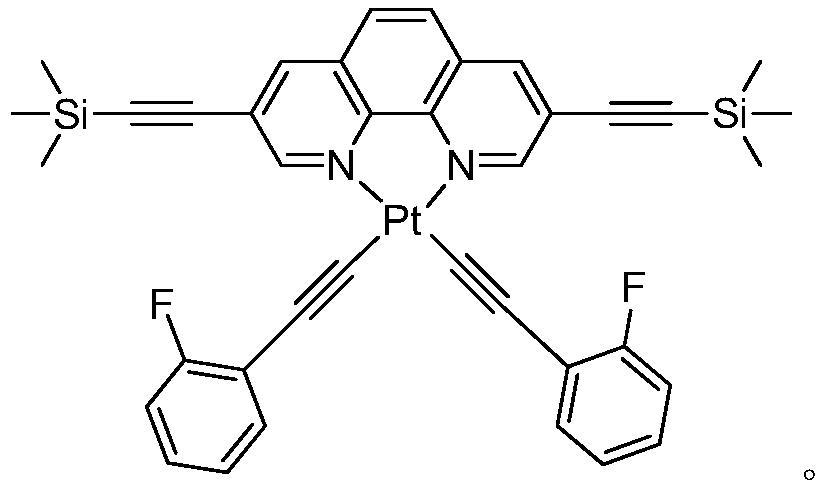

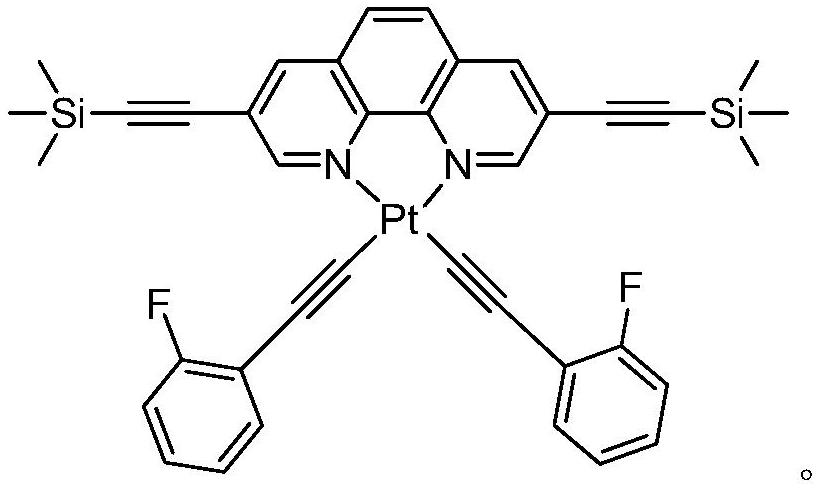

[0021] The configuration of the complex solution: 100mg Pt II (TMSC≡CPhenC≡CTMS)(C≡CC 6 h 4 F-2) 2 Add the complex into 100mL of dichloromethane solvent, stir and dissolve evenly at room temperature to obtain a divalent platinum complex solution;

[0022] Hydrophobic treatment of test strips: Soak the test paper base material in the silylating reagent hexadecyltrimethoxysilane and absolute ethanol solution for 30min, the ratio of silylating reagent and absolute ethanol is 1:5, take it out and dry it spare.

[0023] Preparation of test paper for visual detection of benzene series: soak the base material of the test paper after hydrophobization treatment in step (2) in the divalent platinum complex solution prepared in step (1) for 1 hour, and dry to obtain test paper for visual detection of benzene series.

[0024] Test results of the test paper: put the test paper in the benzene vapor atmosphere, the color of the test paper will change from yellow to orange red soon, when ...

Embodiment 2

[0026] The configuration of the complex solution: 400mg Pt II (TMSC≡CPhenC≡CTMS)(C≡CC 6 h 4 F-2) 2 Add the complex into 100mL of dichloromethane solvent, stir and dissolve evenly at room temperature to obtain a divalent platinum complex solution;

[0027] Hydrophobic treatment of test strips: Soak the test paper base material in the silylating reagent hexadecyltrimethoxysilane and absolute ethanol solution for 30 minutes, the ratio of silylating reagent and absolute ethanol is 1:10, take it out and dry it spare.

[0028] Preparation of test paper for visual detection of benzene series: soak the base material of the test paper after hydrophobization treatment in step (2) in the divalent platinum complex solution prepared in step (1) for 1 hour, and dry to obtain test paper for visual detection of benzene series.

[0029] Test results of the test paper: put the test paper in the toluene vapor atmosphere, the color of the test paper changes from yellow to orange-red quickly, ...

Embodiment 3

[0031] The configuration of the complex solution: 700mg Pt II (TMSC≡CPhenC≡CTMS)(C≡CC 6 h 4 F-2) 2 Add the complex into 100mL of dichloromethane solvent, stir and dissolve evenly at room temperature to obtain a divalent platinum complex solution;

[0032] Hydrophobic treatment of the test strip: Soak the test paper base material in the solution of silylating reagent hexadecyltrimethoxysilane and absolute ethanol for 30 minutes, the ratio of silylating reagent and absolute ethanol is 1:15, take it out and dry it spare.

[0033] Preparation of test paper for visual detection of benzene series: immerse the base material of the test paper after hydrophobization treatment in step (2) in the divalent platinum complex solution prepared in step (1) for 1.5 h, and dry to obtain test paper for visual detection of benzene series.

[0034] Test results of the test paper: put the test paper in the atmosphere of chlorobenzene vapor, the color of the test paper changes from yellow to ora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com