Embedded features for interlocks using additive manufacturing

A technology for identifying features and characteristics, applied in the manufacture of components with interlocking and embedded identification features, and in the field of additive manufacturing, it can solve the problem of not being able to judge that the system contains components that meet the expected specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

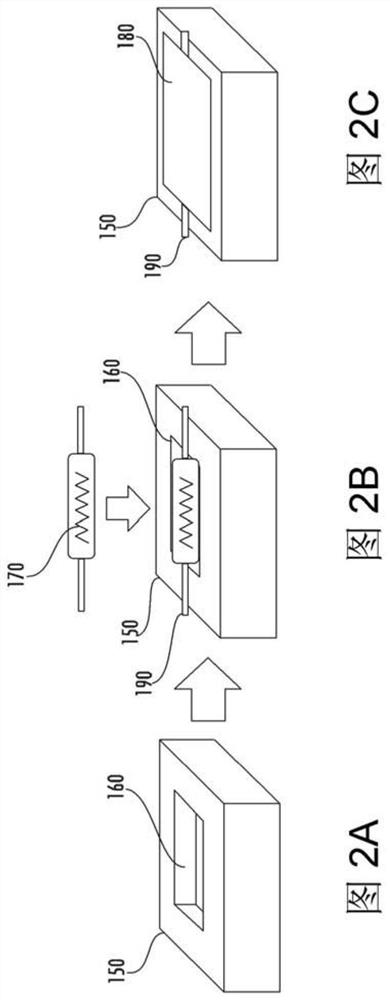

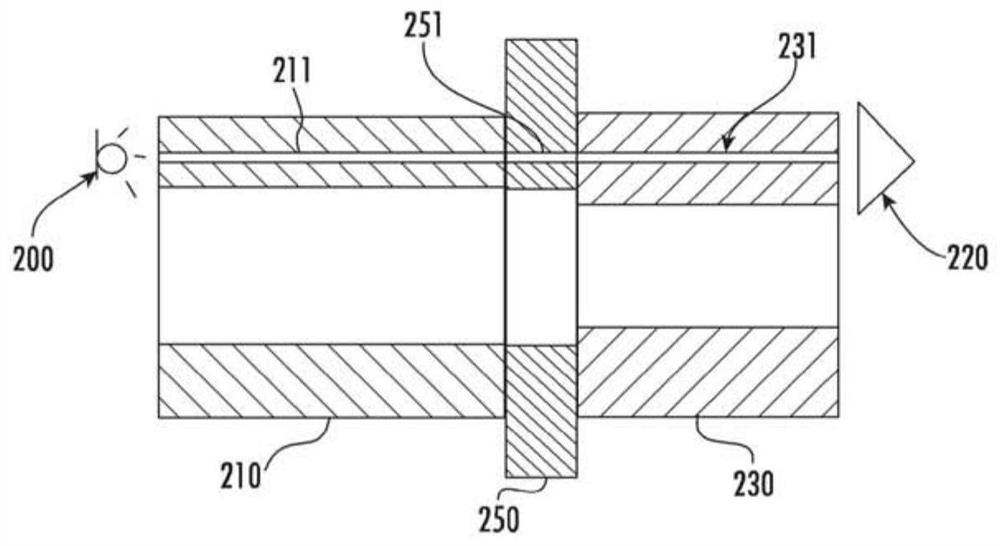

[0021] As mentioned above, a semiconductor manufacturing system may be composed of multiple components. Identification features may be embedded in any or all of these components to allow the system to identify the component. An identification feature can be any element that can be used to identify a component. In some embodiments, the component may be an annular ring, such as a gasket, flange, or other similar component. In other embodiments, the components may be rectangular in shape. Of course, the components can also be of any other shape.

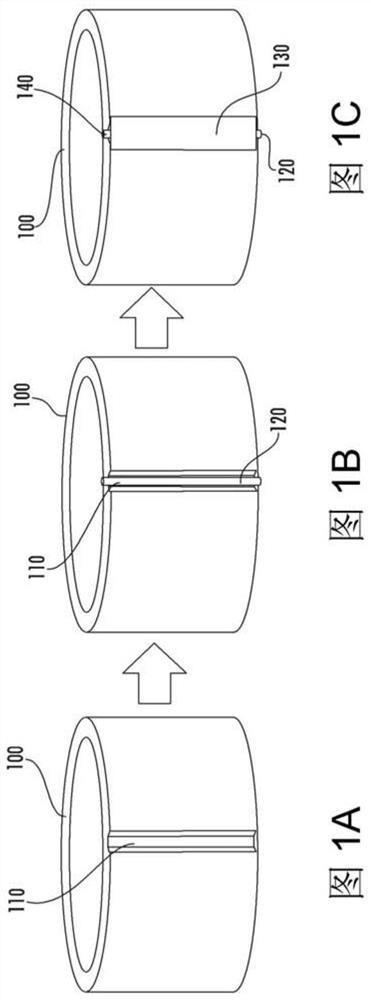

[0022] Figure 1A to Figure 1C The sequence used to embed the identifying features into the assembly is shown. Figure 1A Assembly 100 is shown shaped as an annular ring or hollow cylinder. First, if Figure 1A As shown, cavities 110 may be introduced subtractively into the side walls of component 100 . This cavity 110 may be in the form of a channel in some embodiments. The cavity 110 can be made by grinding, etching or any othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com