Method for treating organic waste gas by bio-trickling filter based on convolutional neural network

A technology of convolutional neural network and biological trickling filter, which is applied in neural learning methods, biological neural network models, separation methods, etc., can solve the problems of energy waste and the inability to fully utilize the processing capacity of biological purification systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for treating organic waste gas with a biological trickling filter based on a convolutional neural network, comprising:

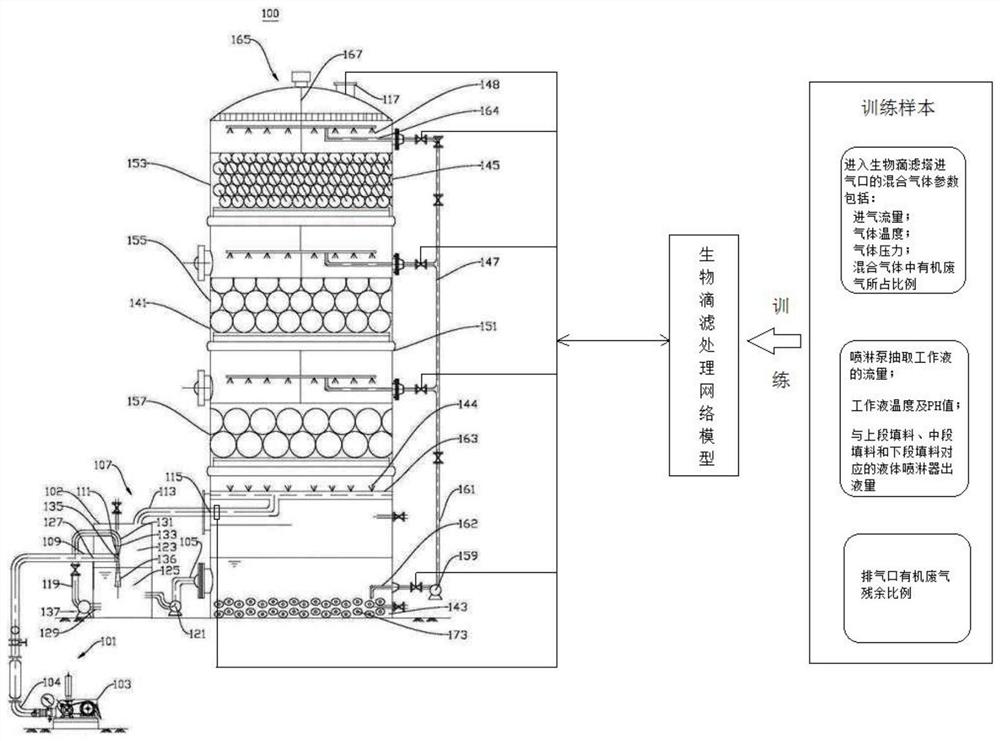

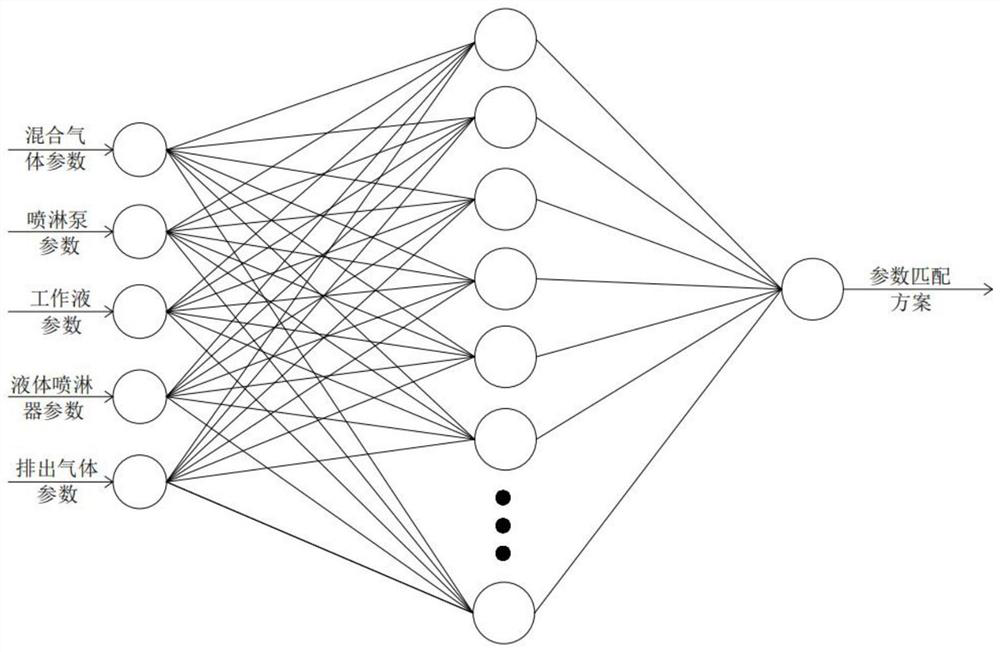

[0029] S10. Constructing a biological trickling treatment network model based on a convolutional neural network; the structure of the biological trickling treatment network model is as follows figure 2 shown.

[0030] In this embodiment, the convolutional neural network includes an input layer, a convolutional layer, and a pooling layer. The number of convolutional layers is 16, the convolutional kernel size is 3*3, and the maximum pooling layer is 5. layer.

[0031] S20, using the training samples to train the biological trickling filtration processing network model;

[0032] In the present embodiment, the training samples include the following parameters: the parameters of the mixed gas entering the air inlet 115 of the biotrickling filter 100, the parameters of the spray pump 159, the parameters of the working fluid, the parameters of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com