Fan control method in ultraviolet curing equipment and ultraviolet curing equipment

A curing equipment, UV technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of unstable cooling effect and unstable wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

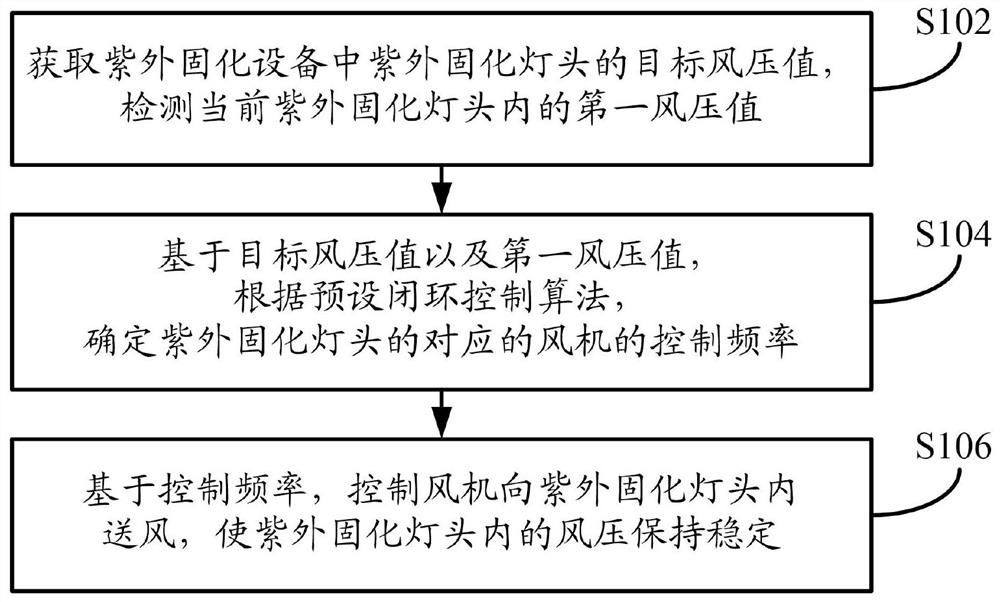

[0077] Such as figure 1 As shown, the embodiment of the present invention provides a fan control method in ultraviolet curing equipment. The execution subject of the method may be the controller of the ultraviolet curing equipment, or it may be an ultraviolet curing equipment with a current adjustment mechanism, or it may be an ultraviolet curing equipment. The server of the device can be an independent server or a server cluster composed of multiple servers. The method specifically may include the following steps:

[0078] In S102, the target wind pressure value of the ultraviolet curing lamp head in the ultraviolet curing device is obtained, and the first wind pressure value in the current ultraviolet curing lamp head is detected.

[0079] The principle of ultraviolet curing (that is, UV Cure) is to use the energy of high-energy photons to "break" and reconstruct the chemical bonds in the film to form new chemical bonds and network structures, thereby reducing the dielectri...

Embodiment 2

[0092] Such as Figure 4 As shown, the embodiment of the present invention provides a fan control method in ultraviolet curing equipment, the method may specifically include the following steps:

[0093] In S402, the first wind pressure value in the current ultraviolet curing lamp head is detected.

[0094] For the specific processing procedure of the above S402, reference may be made to the related content of S102 in the above Embodiment 1, which will not be repeated here.

[0095] In S404, the lamp head power of the ultraviolet curing lamp head is obtained, and based on the preset corresponding relationship between the lamp head power and the target wind pressure value, the target wind pressure value corresponding to the lamp head power is obtained.

[0096] Preferably, according to the heating level and cooling requirements of the UV curing lamp head under different powers, a power and wind pressure correspondence table (that is, the preset correspondence between the lamp ...

Embodiment 3

[0123] The above is the fan control method in the ultraviolet curing equipment provided by the embodiment of the present invention. Based on the same idea, the embodiment of the present invention also provides a fan control device in the ultraviolet curing equipment, such as Image 6 shown.

[0124] The fan control device in the ultraviolet curing equipment includes: a first acquisition module 601, a first determination module 602 and a control module 603, wherein:

[0125] The first acquisition module 601 is used to acquire the target wind pressure value of the ultraviolet curing lamp head in the ultraviolet curing equipment, and detect the first wind pressure value in the current ultraviolet curing lamp head;

[0126] The first determination module 602 is configured to determine the control frequency of the corresponding fan of the UV curing lamp head according to the preset closed-loop control algorithm based on the target wind pressure value and the first wind pressure val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com