Production process of large truck hub brake spring A

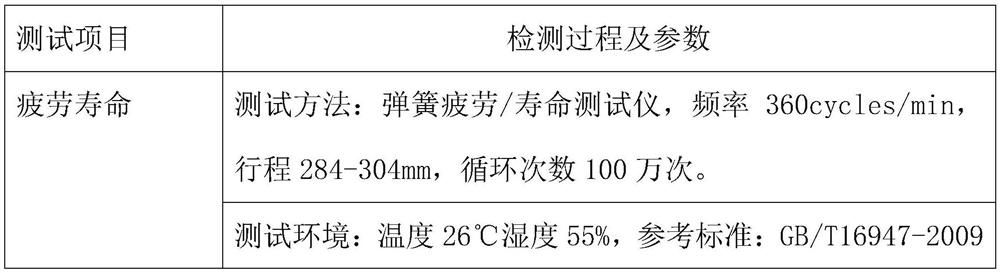

A production process and technology of brake springs, which are applied in the direction of manufacturing tools, wire processing, and springs from wires, etc., can solve the problems of the harsh working environment of the brake spring A of the wheel hub of a large truck and the inability of the brake spring of the wheel hub of the large truck to meet the performance requirements, etc. To achieve the effect of improving fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

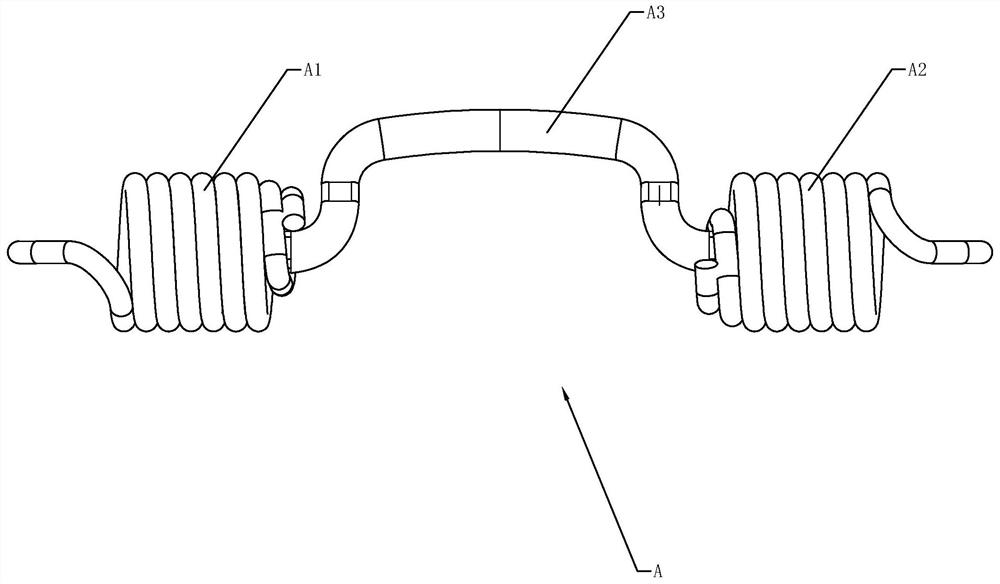

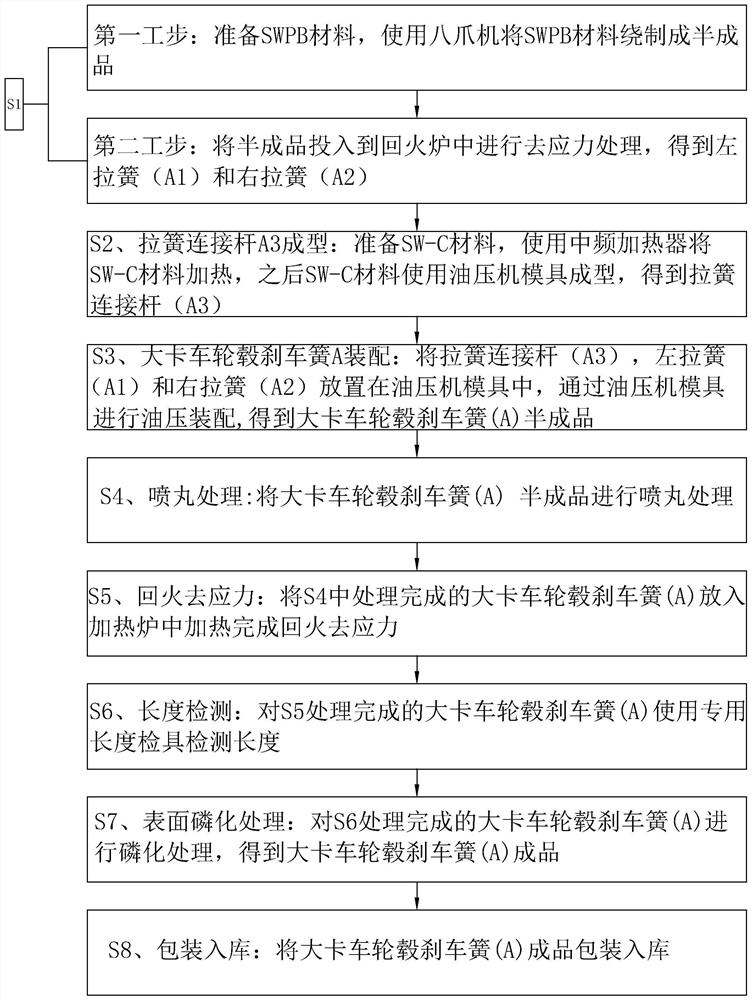

[0028] Embodiment: a kind of production technology of big truck hub brake spring A, as figure 2 shown, including the following steps:

[0029] Forming of S1, left extension spring A1 and right extension spring A2:

[0030] The first step: prepare SWPB material, SWPB is piano steel wire, its material composition: C: 0.80-0.85, Si: 0.12-0.32, Mn: 0.3-0.6, P: below 0.025, S: below 0.025, Cu: 0.2 the following. According to the design structure of the left extension spring A1 and the right extension spring A2, through computer programming, the SWPB material is wound into a semi-finished product using an eight-claw machine.

[0031] The second step: Put the semi-finished product into the tempering furnace for stress relief treatment. The tempering furnace heats the semi-finished product to 300°C, and performs stress relief treatment at 300°C for 30 minutes to obtain the left tension spring A1 and the right tension spring A2. .

[0032] S2. Molding of tension spring connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com