A multi-row drilling machine with multiple holes for stainless steel pipe mufflers

A stainless steel pipe and muffler technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, positioning devices, etc., can solve the problems of uneven force on the muffler, affecting drilling accuracy, and poor practicability. Achieve the effects of improving practicability and flexibility, facilitating recycling, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

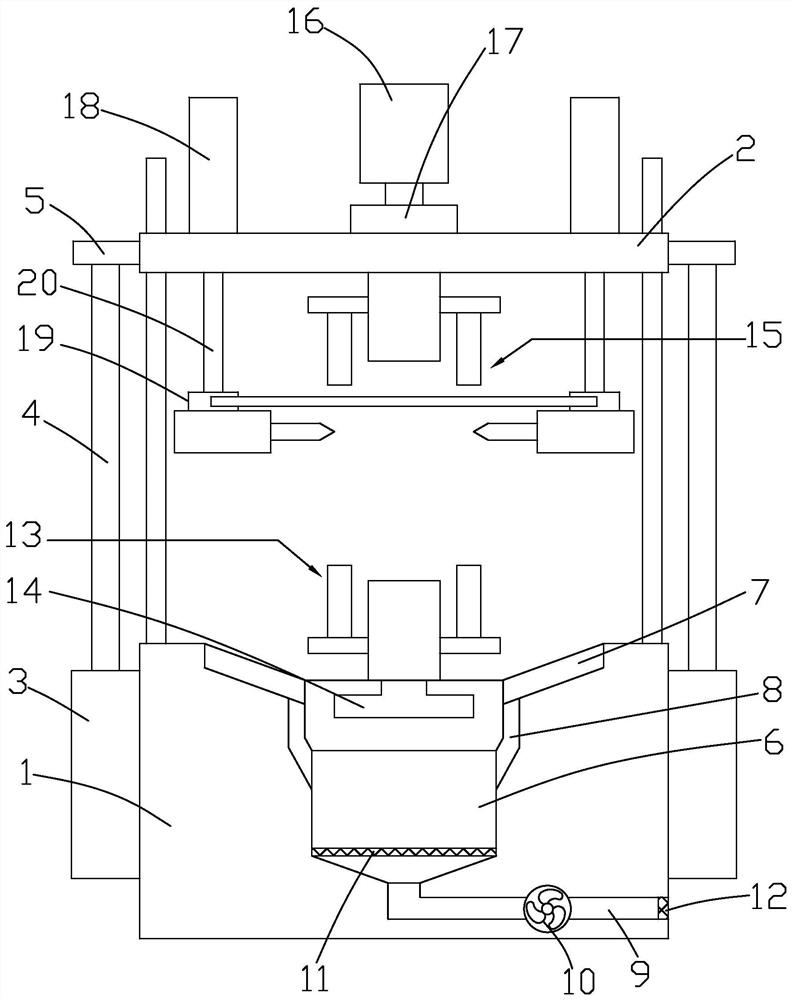

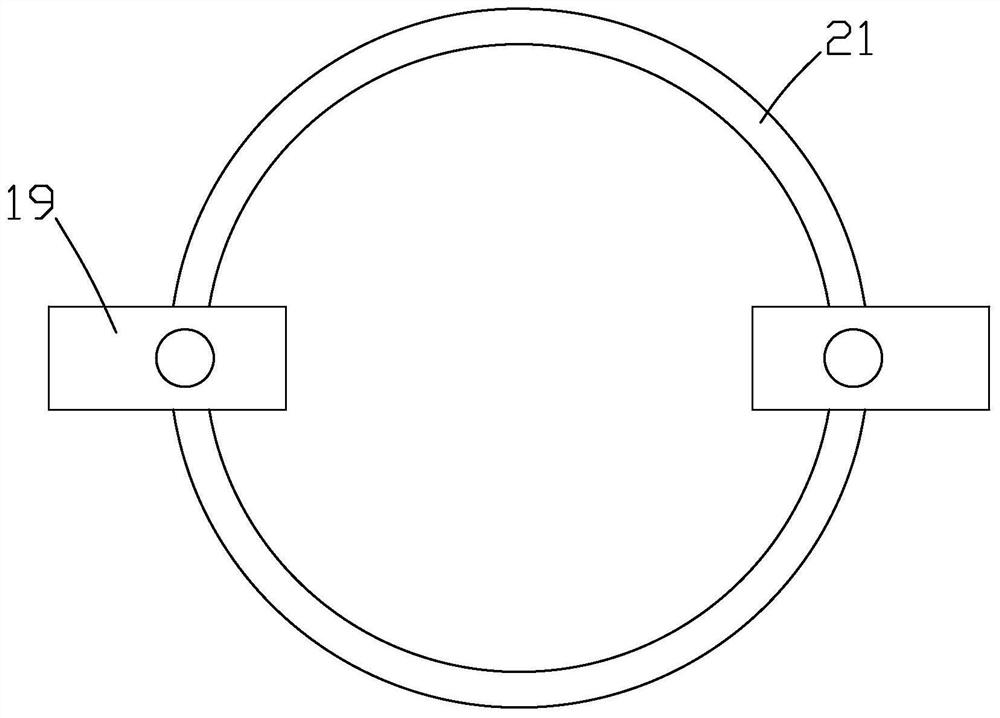

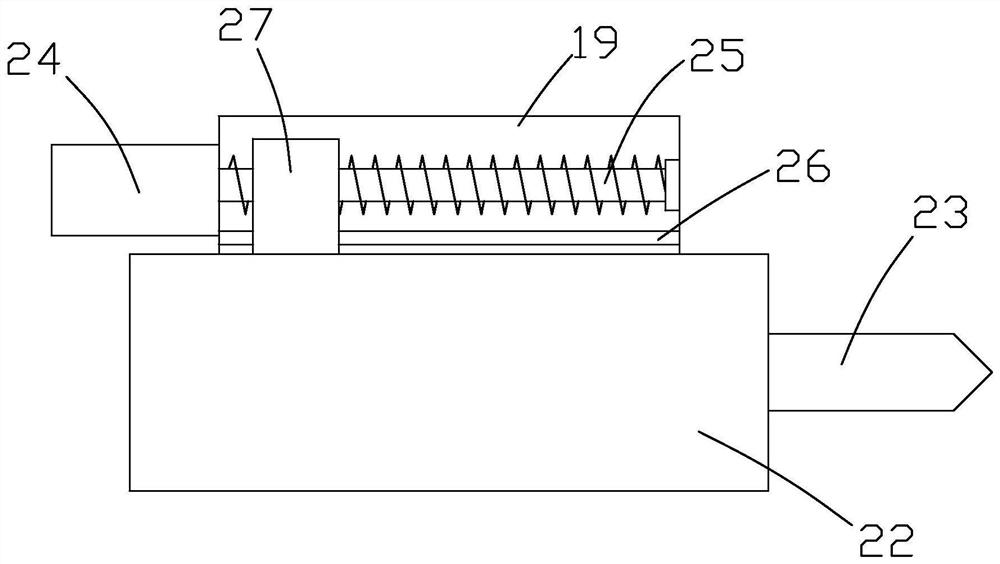

[0029] Such as Figure 1 to Figure 5As shown, it is a multi-row drilling machine with multiple holes for stainless steel pipe mufflers according to the present invention, including machine base 1, lifting platform 2, debris processing mechanism, first clamping mechanism 13, and second clamping mechanism 15 and the drilling mechanism, the lifting platform 2 is connected above the machine base 1 through the lifting assembly, the lifting assembly includes the first cylinder 3, the first piston rod 4, the ear plate 5 and the positioning rod, the ear plate 5 is fixedly connected to the lifting platform 2 On the side of the base, the first cylinder 3 is fixedly connected to the side of the base 1, the first cylinder 3 is connected to the ear plate 5 through the first piston rod 4, the bottom end of the positioning rod is fixedly connected to the top surface of the base 1, and the positioning The top of the rod runs through the lifting plate, the first cylinder 3 drives the first pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com