Heavy-load truss transfer robot

A technology for handling robots and trusses, which is used in manipulators, program-controlled manipulators, non-electric welding equipment, etc., can solve the problems of high feeding cost and low feeding efficiency, save labor, accurate and efficient feeding process, and reduce processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

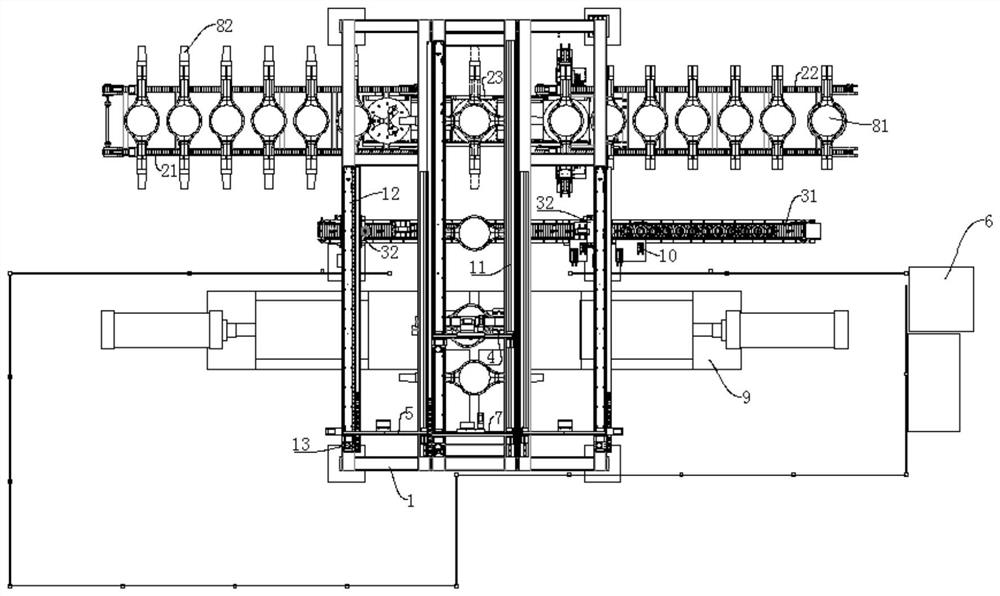

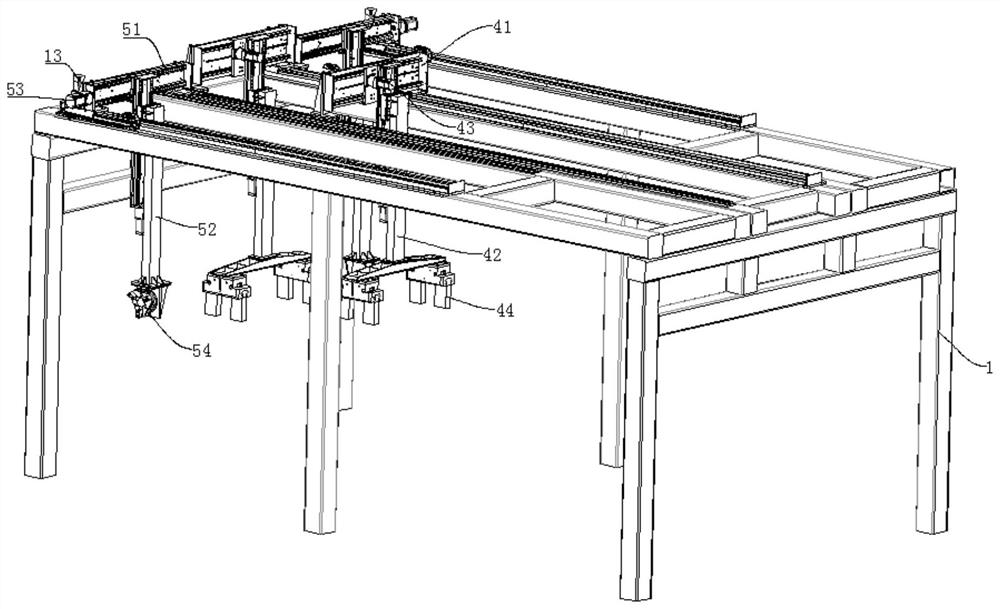

[0027] Such as Figure 1 to Figure 4 As shown, a heavy-duty truss handling robot includes a truss 1, an axle housing conveying device, a shaft head feeding device, an axle housing grabbing manipulator, and a shaft head feeding manipulator, and the axle housing conveying device and The shaft head feeding device and the axle housing conveying device are located in front of the shaft head feeding device, and the clamping welding area is formed under the rear part of the truss 1 .

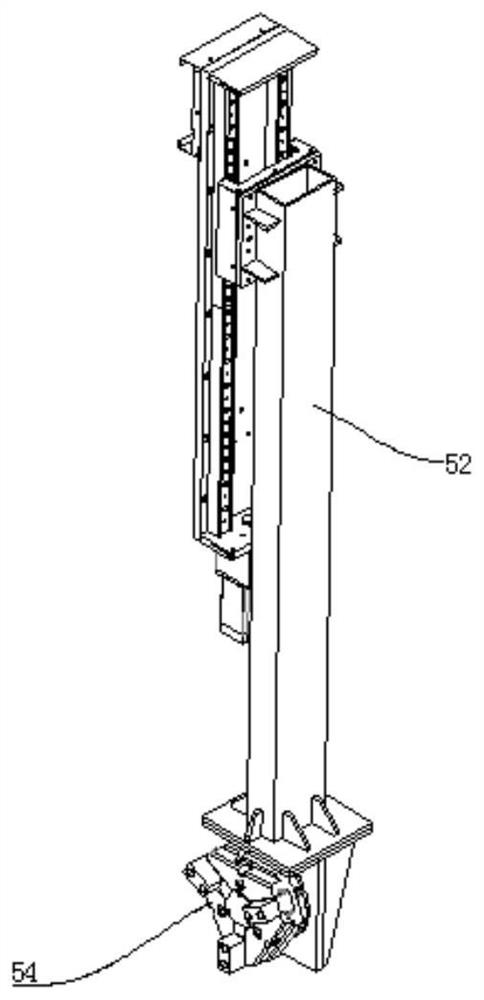

[0028] The top of the truss 1 is provided with a first slide rail 11 between the axle housing conveying device and the clamping welding area, and the axle housing grabbing manipulator is slid on the first slide rail 11, and the axle housing grabbing manipulator includes a first support beam 41, The first lifting arm 42, the second driving device 43 and the mechanical gripper 44, the first support beam 41 is arranged laterally and slides on the first slide rail 11, and the upper end of the first lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com