Monochromatic organic master batch, preparation method and application thereof, and color master batch

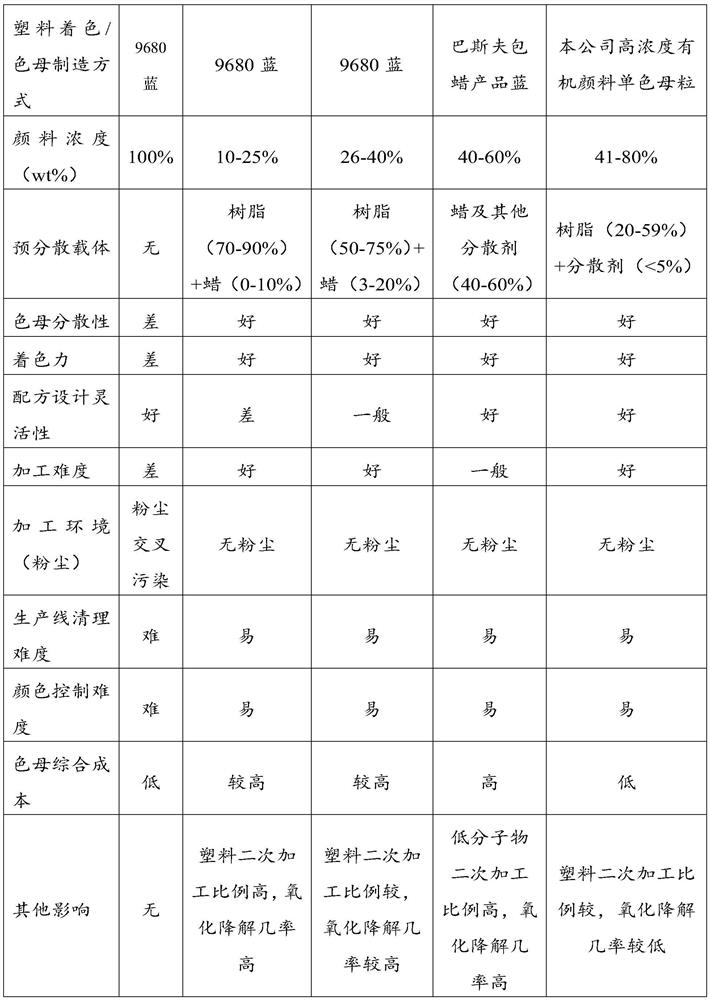

An organic, monochromatic technology, applied in the field of pigments, can solve the problems of poor coloring strength of color masterbatch, low organic pigment dispersion and high cost, and achieve the effects of good coloring strength, low cost impact and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] In addition, the present application correspondingly proposes a method for preparing the above-mentioned single-color organic masterbatch, which may include the following steps: mixing each raw material under heating conditions and then granulating.

[0064] Compared with the processing method in the prior art that only mixes the mixture of organic pigment and polyolefin resin in a mixer and then extrudes, this method can improve the dispersibility of the organic pigment and produce a high-concentration single-color masterbatch.

[0065] For reference, the mixing temperature in this application can be 50-100°C, such as 50°C, 55°C, 60°C, 65°C, 70°C, 75°C, 80°C, 85°C, 90°C, 95°C or 100°C etc. Specifically, a certain temperature within the above-mentioned temperature range can be maintained during the entire mixing process, or the temperature can be fluctuated in a small range within the above-mentioned range during the entire mixing process. The mixing time can be 10-30 m...

Embodiment 1

[0082] This embodiment provides an organic single-color masterbatch. The raw materials of the single-color organic masterbatch include 70wt% of organic pigment, 27wt% of polyolefin resin and 3wt% of dispersant in weight percentage.

[0083] Among them, the organic pigment is pigment red 48:2, the polymer material is PE, and the dispersant is hyperdispersant.

[0084] The single-color organic masterbatch is prepared through the following steps:

[0085] Mix the above-mentioned organic pigments, PE and dispersant according to the proportion in a continuous mixing mode at 75° C. for 20 minutes. Then it is cooled, crushed and transported to a twin-screw extruder with seven zones equipped with a vacuum degassing device for extrusion molding. The temperature of zone 1 to zone 7 is 100°C, 125°C, 165°C, 165°C, 165°C, 165°C and 155°C respectively, and the die head temperature is 145°C. The screw speed during extrusion was 800 rpm.

[0086] After granulation, the machine head is used...

Embodiment 2

[0089] This embodiment provides an organic single-color masterbatch. The raw materials of the single-color organic masterbatch include 70wt% organic pigment, 25wt% polyolefin resin and 5wt% dispersant by weight percentage.

[0090] Among them, the organic pigment is 70% of pigment red 48:2, the polymer material is PE and ethylene copolymer, and the dispersant is hyperdispersant.

[0091] The single-color organic masterbatch is made the same as in Example 1 through the following steps.

[0092] The coloring strength of the obtained single-color organic masterbatch is 104%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com