Continuous biomass carbonization device and method

A biomass carbonization device technology, applied in rotary carbonization furnaces, special forms of dry distillation, petroleum industry, etc., can solve the problems of screw shaft bending, easy blockage of exhaust pipes, affecting the normal operation of equipment, etc., to increase added value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

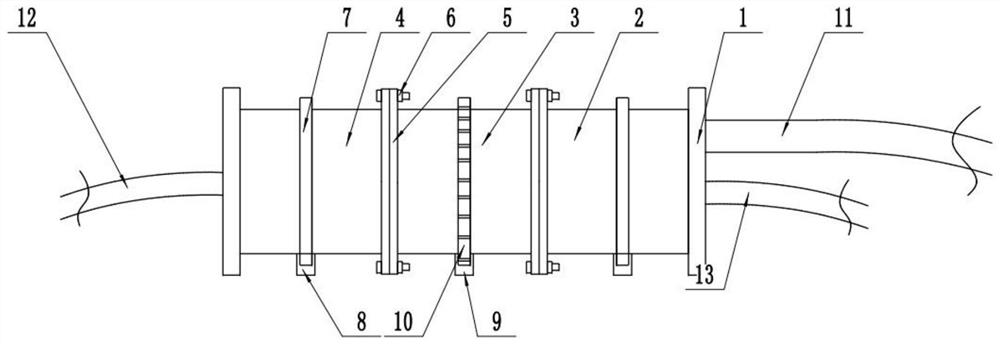

[0032] Such as figure 1 As shown, this embodiment provides a continuous biomass carbonization device, including a frame 1 and a roasting cylinder 2 and a pyrolysis carbonization cylinder 3 that are rotatably mounted on the frame 1, wherein the frame 1 includes two parallel Circular support seat, the lower part of the support seat is fixed by the bottom bracket, the front feed port of the roasting cylinder 2 is connected to the first circular support seat in rotation, and the support seat is provided with a feed port, an exhaust port and a roasting The cylinder 2 is connected, the feed port is used to connect the feed pipe 11, and the exhaust port is used to connect the exhaust pipe 13, and the feed pipe 11 and the exhaust pipe 13 are all provided with valves, preferably ball valves; the roasting cylinder 2 and The pyrolysis and carbonization cylinder 3 is connected in sequence, the roasting cylinder 2 is used for roasting biomass, the pyrolysis and carbonization cylinder 3 is ...

Embodiment 2

[0049] This embodiment is an improvement made on the basis of Embodiment 1. The improvement is that it also includes an activation cylinder 4, the front end feed port of the activation cylinder 4 and the discharge port of the pyrolysis and carbonization cylinder 3 connected, the rear end of the activation cylinder 4 is rotationally connected with the second support seat, and the rear end of the activation cylinder 4 is provided with a discharge port. When working, the discharge port is closed. After the work is completed, the discharge port is opened for In connection with the carbon box; the activation cylinder 4 is also provided with an activation device, which includes a self-activation device and / or a microwave activation device;

[0050] In this embodiment, the self-activation device includes a self-activation pipe, the exhaust pipe 13 is connected with a steam boiler, the inlet of the self-activation pipe is connected with the steam outlet of the steam boiler, and the sel...

Embodiment 3

[0058] This embodiment is an improvement on the basis of Embodiments 1 and 2. The improvement is that a discharge port is provided at the bottom of the second support seat, and the discharge port is connected with the activation cylinder 4 or the pyrolysis carbonization cylinder 3 Connection, the discharge port is connected with the carbon box through the discharge pipe, and a valve is set at the discharge port.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com