Method for evaluating cigarette perfuming uniformity

A uniformity, cigarette technology, applied in the field of analysis and detection, can solve the problems of difficult qualitative and quantitative, small content, complex cigarette matrix, etc., and achieve the effects of good separation effect, simple pretreatment and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

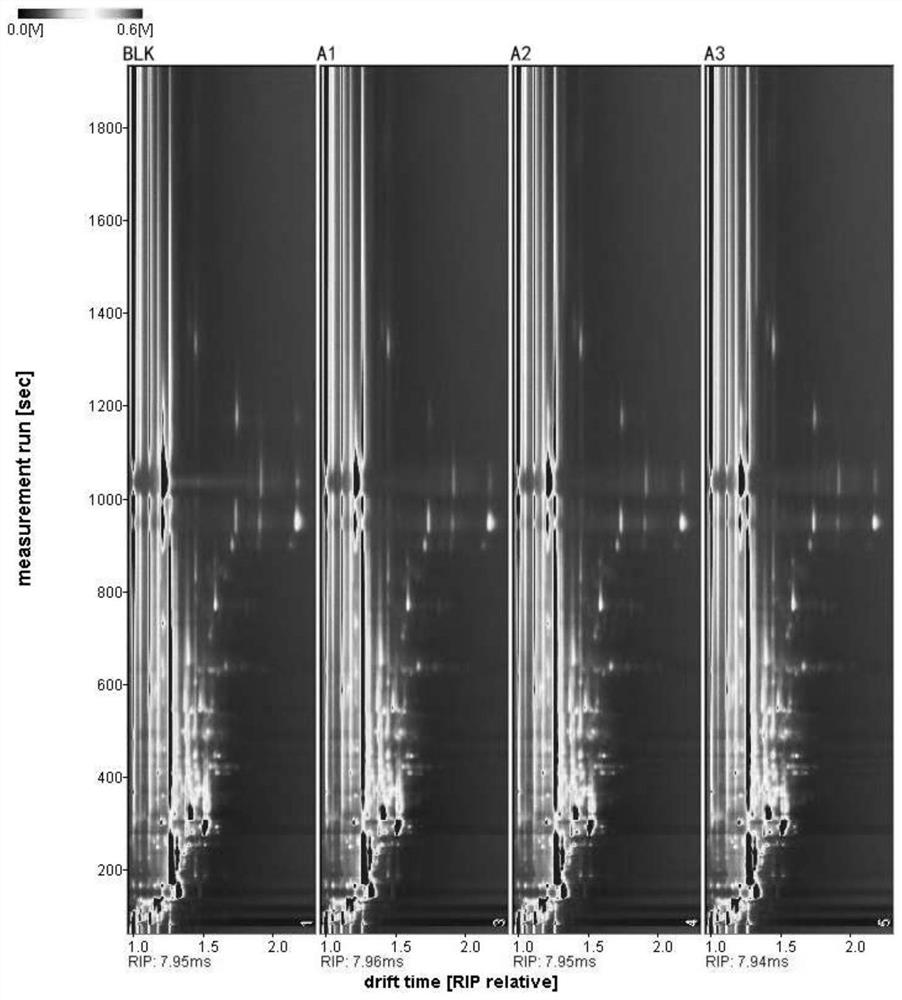

[0075] Example 1: Evaluation of Uniformity of Flavoring of Cigarettes within a Batch

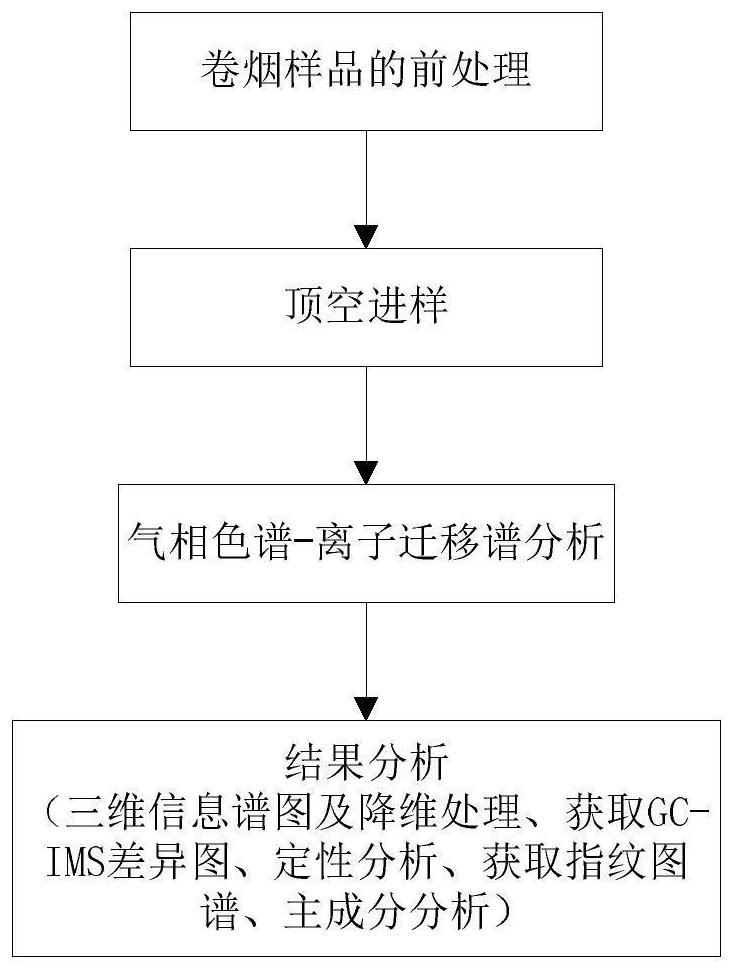

[0076] To evaluate the uniformity of flavoring of cigarettes within a batch, the following technical steps are specifically adopted:

[0077] 1) Pretreatment of cigarette samples

[0078] Take 1 sample of shredded tobacco before flavoring and 3 samples of shredded tobacco after flavoring (the sampling principle is to take samples at intervals of 2 minutes after the flow rate in the flavoring process is stable), and pass through a 40-mesh sieve after freezing and grinding.

[0079] 2) Automatic headspace sampling

[0080] Headspace sampling conditions were: incubation temperature 90°C, incubation time 20min, injection volume 100uL, injection needle temperature 85°C, incubation speed 500rpm.

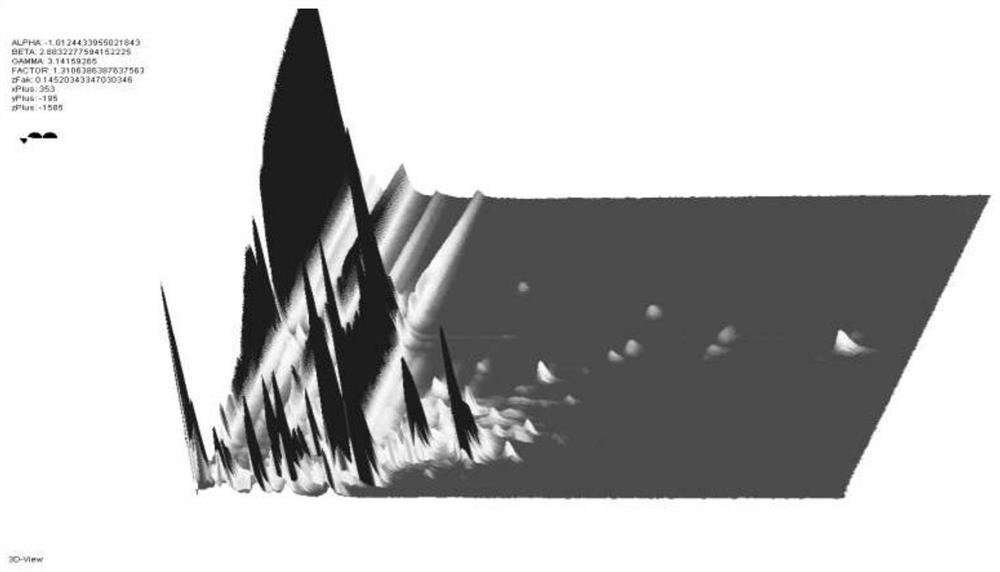

[0081] 3) Gas chromatography-ion mobility spectrometry detection

[0082] The instrument conditions of gas chromatography-ion mobility spectrometry are: analysis time 35min, chromatographic column typ...

Embodiment 2

[0089] Example 2: Evaluation of Uniformity of Flavoring of Cigarettes Between Batches

[0090] To evaluate the uniformity of cigarette flavoring between batches, the following technical steps are specifically adopted:

[0091] 1) Pretreatment of cigarette samples

[0092] One sample of shredded tobacco before flavoring and three samples of shredded tobacco after flavoring were taken from different batches, which were freeze-ground and then passed through a 40-mesh sieve.

[0093] 2) Automatic headspace sampling

[0094] Headspace sampling conditions were: incubation temperature 90°C, incubation time 20min, injection volume 100uL, injection needle temperature 85°C, incubation speed 500rpm.

[0095] 3) Gas chromatography-ion mobility spectrometry detection

[0096] The instrument conditions of gas chromatography-ion mobility spectrometry are: analysis time 35min, chromatographic column type FS-SE-54-CB-115m ID: 0.53mm; column temperature 60°C, carrier gas / drift gas N2 ; IMS t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com