Lithium ion battery short-circuit test method

A lithium-ion battery and short-circuit testing technology, which is applied in short-circuit testing, discharge tube testing, and dielectric strength testing, can solve problems such as analysis and failure to perform root causes, and achieve low cost, qualitative analysis, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

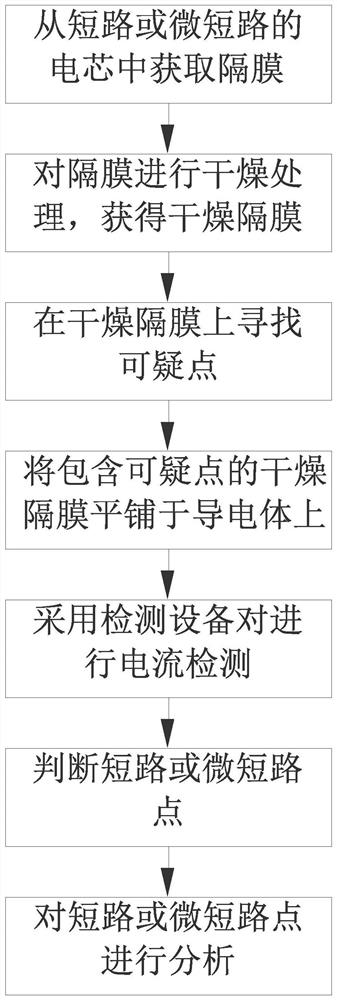

[0091] A method for lithium-ion battery short circuit test, comprising the following steps:

[0092] (1). Disassemble the cell with micro-short circuit and use a magnifying glass to find suspicious black spots on the diaphragm;

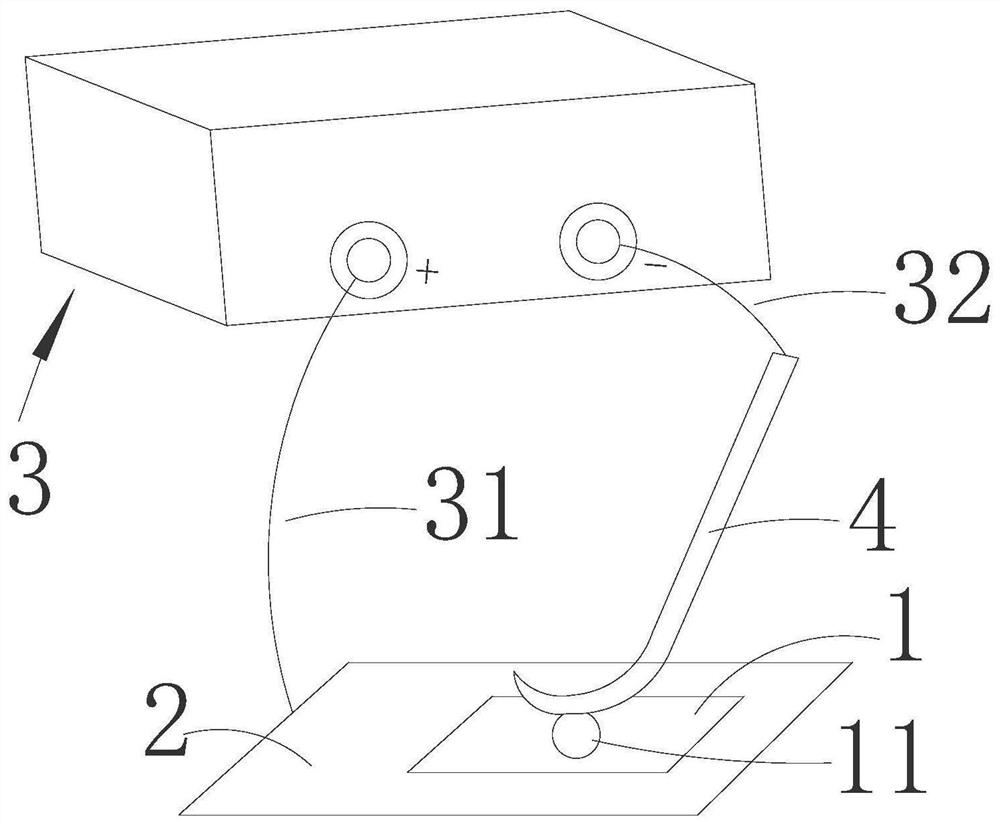

[0093] (2). Put the diaphragm with suspicious black spots in an oven at 45°C for 10 minutes, and cool down to room temperature naturally after drying, then refer to figure 2 As shown in the schematic diagram of the test, the dry diaphragm is laid flat on a clean and dry copper foil, and the surface of the dry diaphragm with suspicious black spots faces upward;

[0094] (3). Use copper foil to make a flat and flexible copper tube at one end;

[0095] (4). Connect one end of the Hi-pot tester to the copper tube and the other end to the copper foil. After adjusting the voltage of the Hi-pot tester to 40V, use the flat end of the copper tube to touch the suspicious black spot on the dry diaphragm, and place the Hi-pot The current value I displayed by t...

Embodiment 2

[0107] A method for lithium-ion battery short circuit test, comprising the following steps:

[0108] (1). Disassemble the cell with micro-short circuit and use a magnifying glass to find suspicious black spots on the diaphragm;

[0109] (2). Put the diaphragm with suspicious black spots in an oven at 30°C for 15 minutes, then cool down to room temperature naturally after drying, and then refer to figure 2 As shown in the schematic diagram of the test, the dry diaphragm is spread on a clean and dry iron plate, and the surface of the dry diaphragm with suspicious black spots faces upward;

[0110] (3). Use copper foil to make a flat and flexible copper tube at one end;

[0111] (4). Connect one end of the Hi-pot tester to the copper pipe and the other end to the iron plate. After adjusting the voltage of the Hi-pot tester to 30V, use the flat end of the copper pipe to touch the suspicious black spot on the dry diaphragm, and place the Hi-pot The current value I displayed by t...

Embodiment 3

[0123] A method for lithium-ion battery short circuit test, comprising the following steps:

[0124] (1). Disassemble the cell with micro-short circuit and use a magnifying glass to find suspicious black spots on the diaphragm;

[0125] (2). Put the diaphragm with suspicious black spots in an oven at 60°C for 8 minutes, and cool down to room temperature naturally after drying, and then refer to figure 2 As shown in the schematic diagram of the test, the dry diaphragm is spread flat on a clean and dry graphite plate, and the surface of the dry diaphragm with suspicious black spots faces upward;

[0126] (3). Use copper foil to make a flat and flexible copper tube at one end;

[0127] (4). Connect one end of the Hi-pot tester to the copper tube and the other end to the graphite plate. After adjusting the voltage of the Hi-pot tester to 20V, use the flat end of the copper tube to touch the suspicious black spot on the dry diaphragm, and place the Hi-pot The current value I dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com