Low-polarization high-diffraction-efficiency metal reflection immersion grating and optical system

A diffraction efficiency and metal reflection technology, applied in the field of gratings, can solve problems such as the degree of polarization and the influence of diffraction efficiency grating groove tolerance, and achieve the effects of reducing manufacturing process difficulty, low polarization, and reducing groove density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

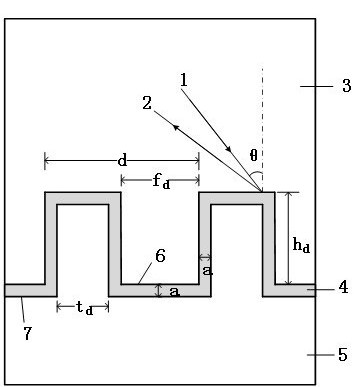

[0054] The material of the grating layer 3 is fused silica optical glass, and the material of the dielectric layer 4 is TiO 2 , the metal reflection layer 5 is silver, the period d of the grating layer 3 is 690 nanometers, the groove depth of the grating layer 3 and the period ratio h are 0.8, the duty ratio f of the grating layer 3 is 0.3, and the duty ratio of the metal reflection layer 5 is t is 0.37. The incident angle θ of the incident light in the grating layer 3 is 47°.

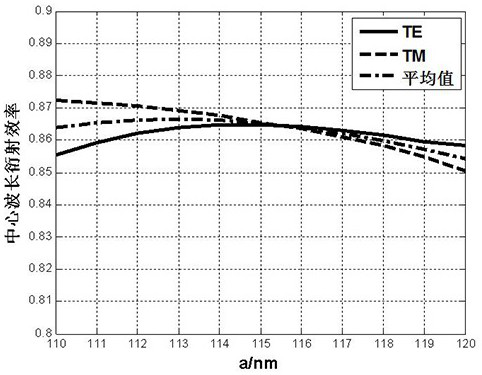

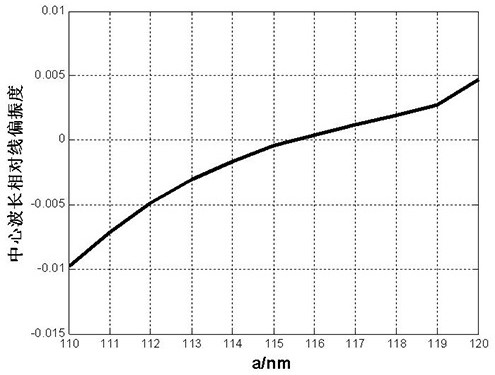

[0055] see figure 2 Shown is the variation curve of the average diffraction efficiency at the central wavelength of the working band with the thickness a of the dielectric layer 4 . image 3 is the variation curve of the relative degree of linear polarization DP at the central wavelength of the working band with the thickness a of the dielectric layer 4; figure 2 and image 3 It can be seen that when the thickness a of the dielectric layer is 115 nm, the immersion grating has better diffraction e...

Embodiment 2

[0058] The material of the grating layer 3 is fused silica optical glass, and the dielectric layer 4 is Al 2 o 3 , the metal reflective layer 5 is silver, the period d of the grating layer 3 is 690 nanometers, the groove depth to period ratio h of the grating layer 3 is 0.8, and the duty cycle t of the metal reflective layer 5 is 0.2. The incident angle θ of the incident light in the grating layer 3 is 48°.

[0059] Figure 5 It is the variation trend of the average diffraction efficiency at the central wavelength of the working band with the thickness a of the dielectric layer 4 and the duty ratio f of the grating layer 3 in embodiment two; The variation trend of the thickness a of the layer 4 and the duty ratio f of the grating layer 3, the colors in the figure indicate the average diffraction efficiency and the relative linear polarization degree. combine Figure 5 and Figure 6 As shown, it can be seen that the duty ratio f of the grating layer 3 is 0.2, the thickness...

Embodiment 3

[0062] The material of the grating layer 3 is fused silica optical glass, and the dielectric layer 4 is TiO 2 , the metal reflection layer 5 is silver, the period d of the grating layer 3 is 1010 nanometers, the ratio h of the groove depth to the period of the grating layer 3 is 0.8, and the duty ratio t of the metal reflection layer 5 is 0.4. The incident angle θ of the incident light in the grating layer 3 is 43°.

[0063] Fig. 8 is the variation trend of the average diffraction efficiency at the central wavelength of the working band with the thickness a of the dielectric layer 4 and the duty cycle f of the grating layer 3 in embodiment three; the relative degree of linear polarization DP at the central wavelength of Fig. 9 varies with the dielectric layer The variation trend of the thickness a of 4 and the duty ratio f of the grating layer 3, the colors in the figure indicate the average diffraction efficiency and the relative degree of linear polarization. combine Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com