Indefinite fresh food logistics transportation box

A transport box and logistics technology, applied in fish farming, application, animal husbandry, etc., can solve the problem that oxygen cannot be effectively used, and achieve the effect of improving utilization rate, increasing oxygen supply, and increasing dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

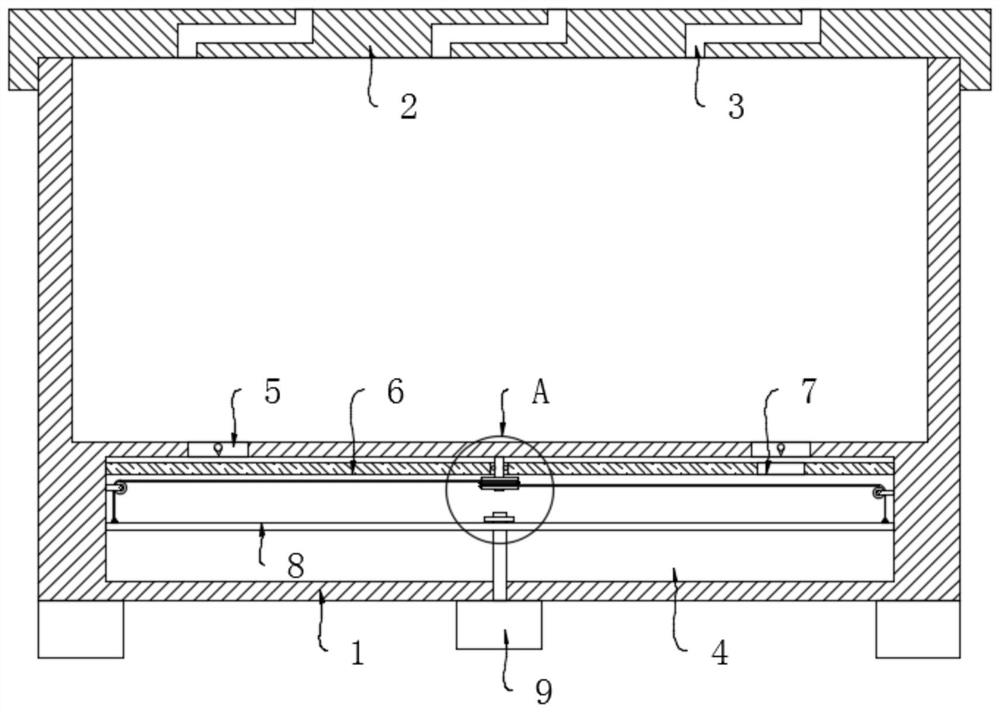

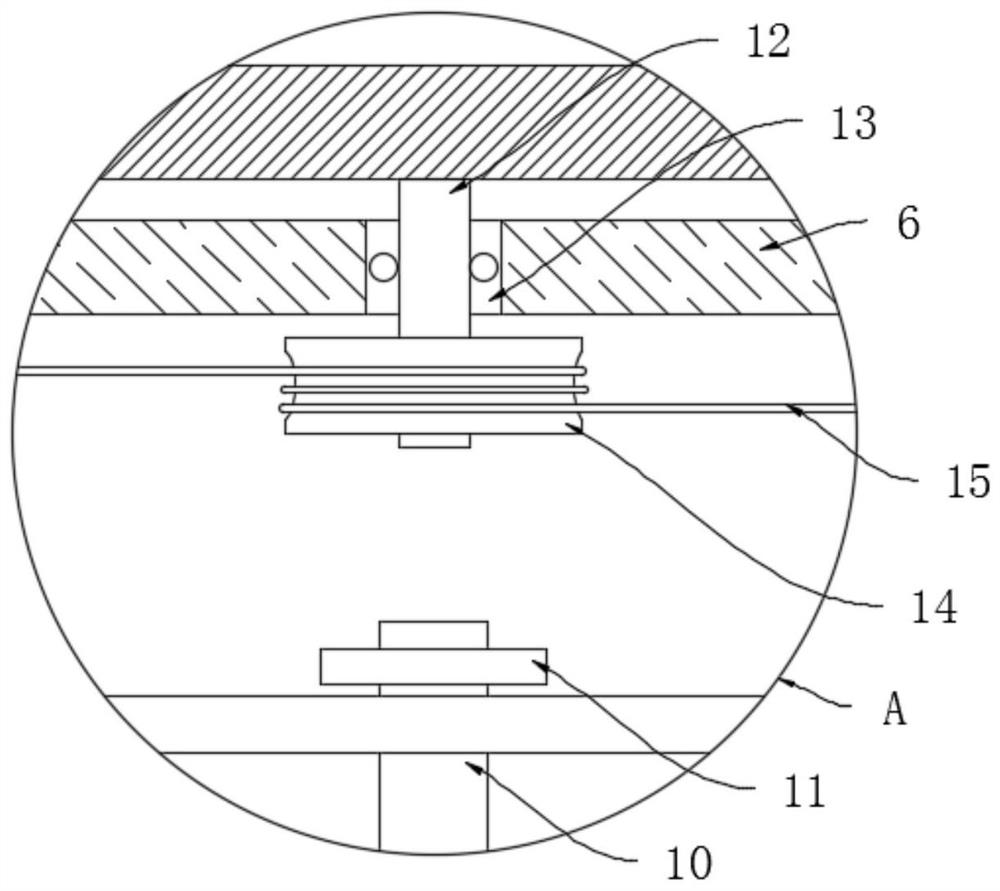

[0022] refer to Figure 1-2 , an indeterminate fresh logistics transportation box, including a box body 1, a box cover 2 is provided at the notch at the upper end of the box body 1, a plurality of vents 3 are uniformly opened on the box cover 2, and the lower side of the box body 1 is coaxially opened There is an installation groove 4, and a plurality of oxygen-increasing tubes 5 are evenly connected between the inner top wall of the installation groove 4 and the inner bottom wall of the box body 1, and the plurality of oxygen-increasing tubes 5 are arranged circumferentially about the vertical axis of the box body 1, Each oxygenation pipe 5 is equipped with a one-way pressure valve, and the one-way pressure valve only allows the gas or liquid in the installation tank 4 to pass through the oxygenation pipe 5 when the pressure of the gas or liquid in the installation tank 4 is greater than its preset threshold. Entering the box body 1, the upper middle part of the inner top wal...

Embodiment 2

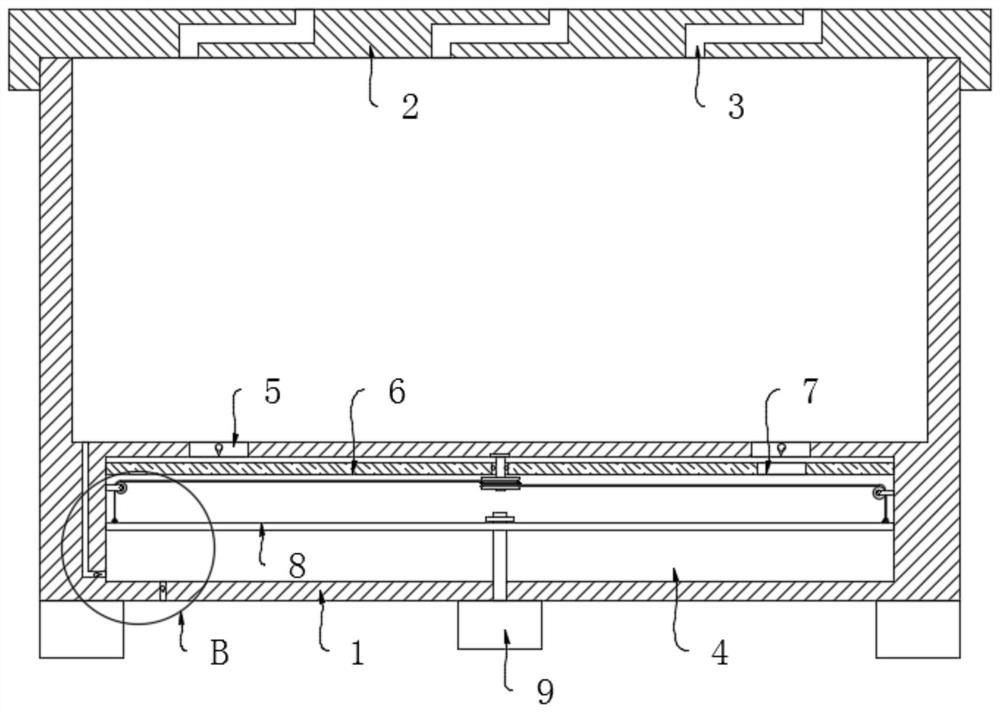

[0028] refer to Figure 3-4 The difference between this embodiment and Embodiment 1 is that: the box body 1 is respectively provided with a plurality of one-way exhaust pipes 17 and one-way air intake pipes 16 which communicate the driving area with the inner bottom wall of the box body 1 and the outside world. A first one-way valve and a second one-way valve are respectively installed in the inlet pipe 16 and the one-way exhaust pipe 17, the first one-way valve only allows the outside gas or liquid to enter the driven area through the one-way inlet pipe 16, and the second one-way valve Two one-way valves only allow gas or liquid in the driven area to be discharged to the outside through the one-way exhaust pipe 17.

[0029] This embodiment can illustrate its functional principle through the following operation mode: when the movable plate 8 moves downward in the installation groove 4 to squeeze the driven area, the gas in the driven area enters the inside of the box body 1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com