Laser cleaning device

A technology of laser cleaning and laser beams, applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as low engineering practicability, inability to improve off-the-shelf systems, difficulty in ensuring beam collimation, etc., achieve long focal depth, increase Depth of focus, efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

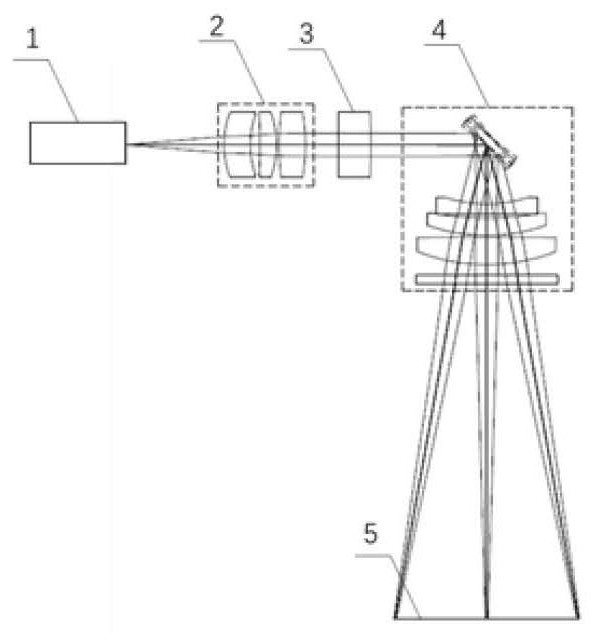

[0028] For a laser cleaning device provided in an embodiment of the present invention, please refer to Figure 1-3 , the laser cleaning device includes:

[0029] A laser generating device 1, which emits a laser beam;

[0030] Specifically, the laser generating device 1 may be an ultraviolet laser, and the laser wavelength is 248nm or 308nm. Since the ultraviolet wavelength is relatively short, and the depth of focus is proportional to the laser wavelength, the focal depth of the corresponding focused spot is doubled. The laser wavelength of the laser 1 can also be selected from other wavelength lasers, such as 10.6um, 532nm or other laser wavelengths, depending on the cleaning material.

[0031] A collimating mirror group 2, the collimating mirror group 2 receives the laser beam and outputs a collimated beam;

[0032] Specifically, the collimating lens group 2 is composed of single or multiple lenses, the collimating lens group 2 is a system for obtaining a high-collimation ...

Embodiment 1

[0058] With regard to Embodiment 1, the embodiment of the present application also provides a method for using a laser cleaning device, which is applied to the laser cleaning device described in Embodiment 1, specifically including:

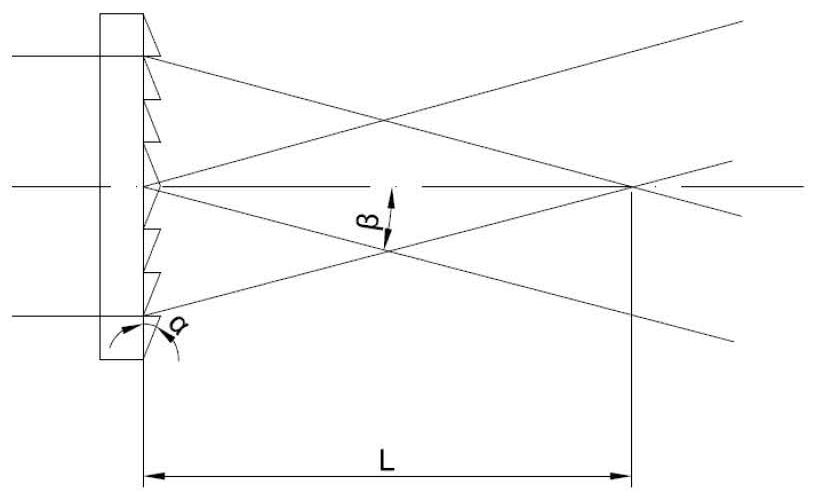

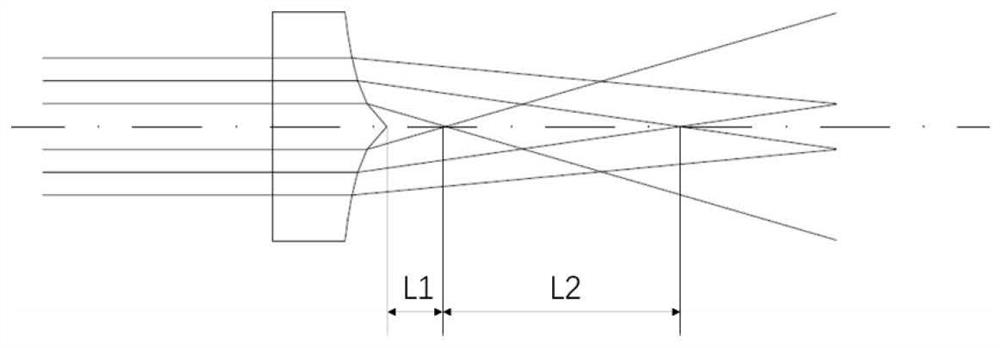

[0059] Before using the device, try to keep the workpiece 5 to be processed directly in front of the light outlet of the scanning focusing system 4. After starting the device, the laser generating device 1 outputs a Gaussian beam or a flat-top beam or other multi-mode beams, from the The laser beam emitted by the laser generating device 1 has a certain divergence angle, and the beam is output as a collimated beam after being passed through the collimating lens group 2, and the collimated beam is transformed into an infinite beam after being shaped and adjusted by the beam shaping element 3. Diffraction Bessel beam, the non-diffraction Bessel beam is focused on the surface of the workpiece 5 to be processed by the scanning focusing system 4, the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com