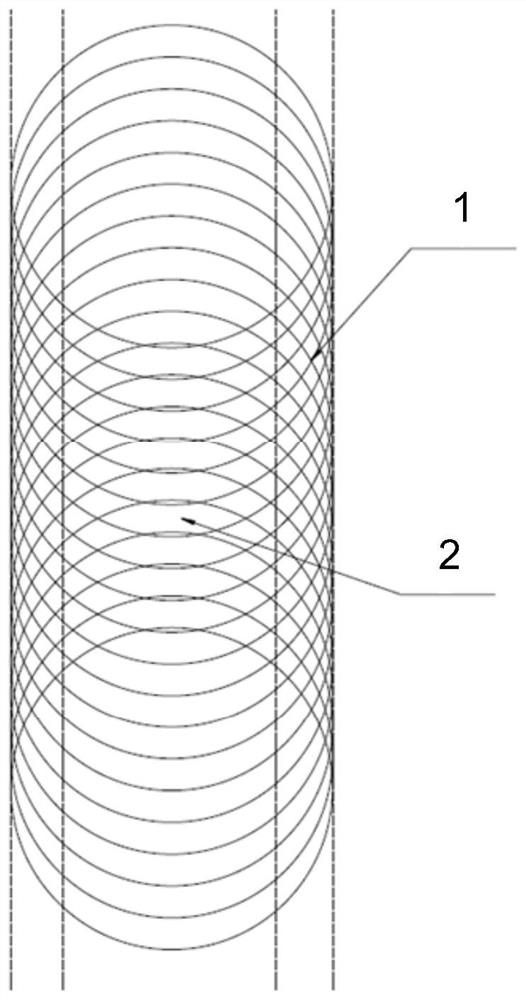

After uniform cooling device and method for wire spinning steel wire rod

A technology of uniform cooling and spinneret, which is applied in workpiece cooling devices, workpiece surface treatment equipment, metal rolling, etc., can solve the problem of temperature unevenness, and achieve the effects of device simplification, convenient operation and maintenance, and uniform and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

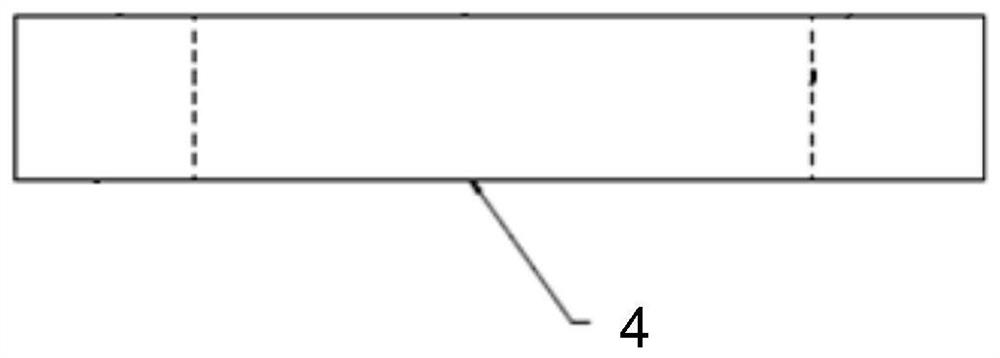

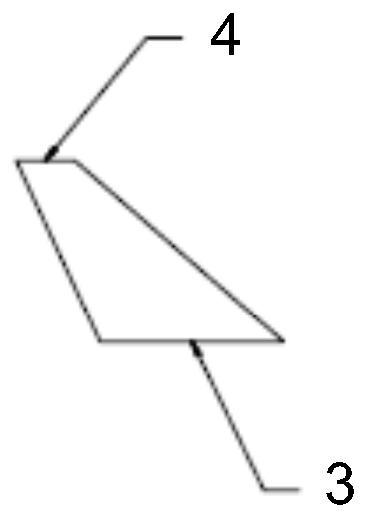

Method used

Image

Examples

Embodiment 1

[0047] Example 1: For a hard wire rod with a diameter of φ5.5mm, the spinning temperature is 880°C, only the tuyere is used, and the water mist nozzle 8 is not used, and the measured temperature difference in the same circle is 55°C.

Embodiment 2

[0048] Example 2: Cold heading steel wire rod with a diameter of φ8mm, spinning temperature 840°C, slow cooling without turning on the fan, using 12 sets of water mist nozzles 8, and installing 1 water mist nozzle at the position 14 of the air nozzle air inlet on the upper side of each cooling device 8. The flow density of water mist nozzle 8 is 17l / m 2 min, the measured temperature difference in the same ring is 70°C.

Embodiment 3

[0049] Example 3: For a hard wire rod with a diameter of φ14mm, the spinning temperature is 860°C, and 8 sets of water mist nozzles 8 are used. Two water mist nozzles 8 and 8 water mist nozzles are installed at the air inlet 14 of the air nozzle on the upper side of each cooling device. The spacing is 80mm, and the flow density of water mist nozzle 8 is 10l / m 2 min, the measured temperature difference in the same ring is 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com