Water tank welding robot device

A welding robot and robot technology, applied in welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of low manual welding efficiency, unstable welding quality, etc., and achieve improved labor intensity, controllable welding time, and batch welding processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

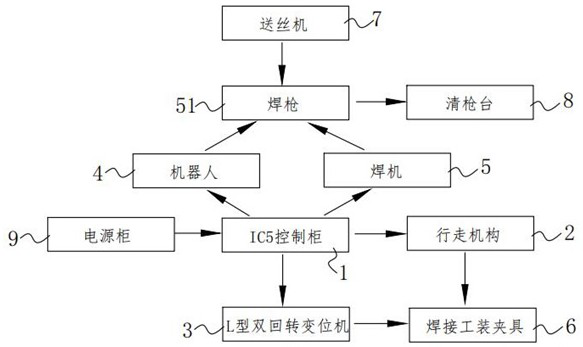

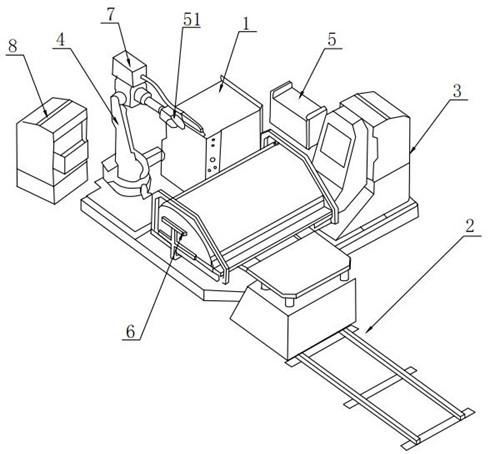

[0025] The invention provides a water tank welding robot device, such as figure 1 and figure 2 As shown, it includes the IC5 control cabinet 1 and the traveling mechanism 2 electrically connected to and controlled by the IC5 control cabinet 1, the L-shaped double-turn positioner 3, the robot 4, and the welding machine 5; the traveling mechanism 2 is installed on the workbench and extending in a straight line, a welding fixture 6 is installed on the traveling mechanism 2, an L-shaped double-rotary positioner 3 is installed on the side of the end of the traveling mechanism 2, and the welding machine 5 includes a welding torch 51, which is connected to the robot 4 and is For the welding fixture 6, the welding machine 5 is connected to the wire feeder 7 and the wire is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com