Tobacco shred blending uniformity determination method based on combination of chromatic value and entropy weight method

A determination method and technology of chromaticity value, applied in the direction of color/spectral property measurement, measurement device, preparation of test samples, etc., can solve the problems of high requirements for instruments and equipment, complex data processing, establishment of identification models, etc., and achieve the cost of instruments. Low, repeatable, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

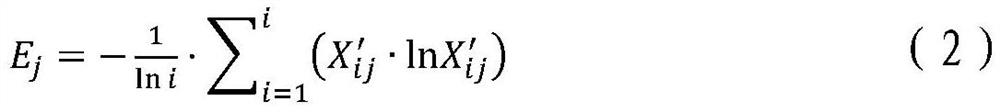

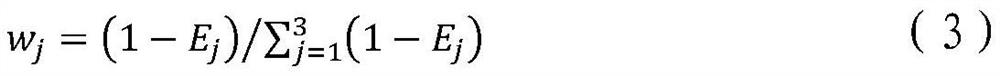

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0029] This application provides a method for measuring the blending uniformity of shredded tobacco based on the chromaticity value combined with the entropy weight method. In the following examples, finished shredded tobacco samples of 4 cigarette brands of Yunyan brand A to D are selected. The shredded tobacco formula is shown in Table 1. Show.

[0030] Table 1 Composition of shredded tobacco of cigarette brands A to D

[0031] Grade Leaf shreds / % Stem / % Shredded reconstituted tobacco / % A 75 15 10 B 84 6 10 C 80 13 7 D 83 10 7

[0032] FED programmable hot air circulation oven, KBF 540 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com