Steel strip coil stock on-line shearing welding machine

A technology for welding machines and steel strip coils, which is applied to metal processing machinery parts, clamping, support, etc., and can solve problems such as affecting the quality of coil connection, large tolerance deviation, and plate warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

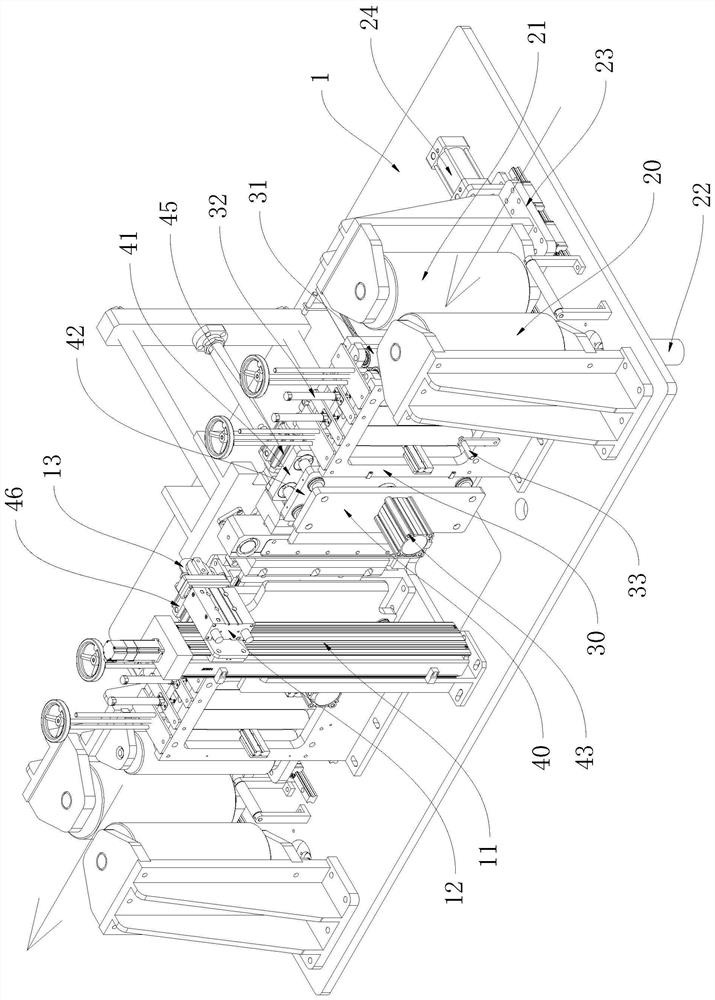

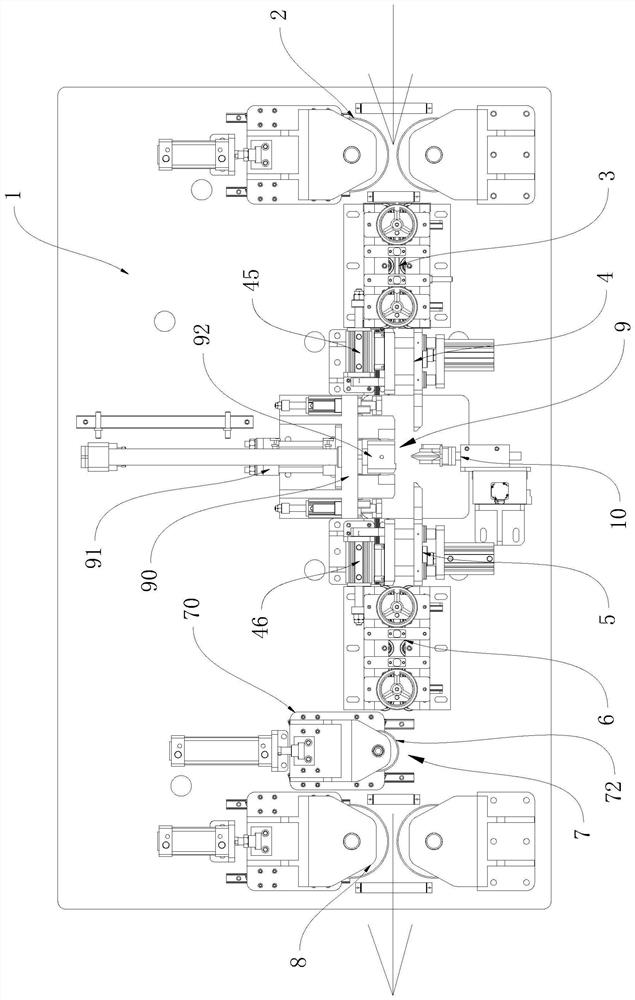

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

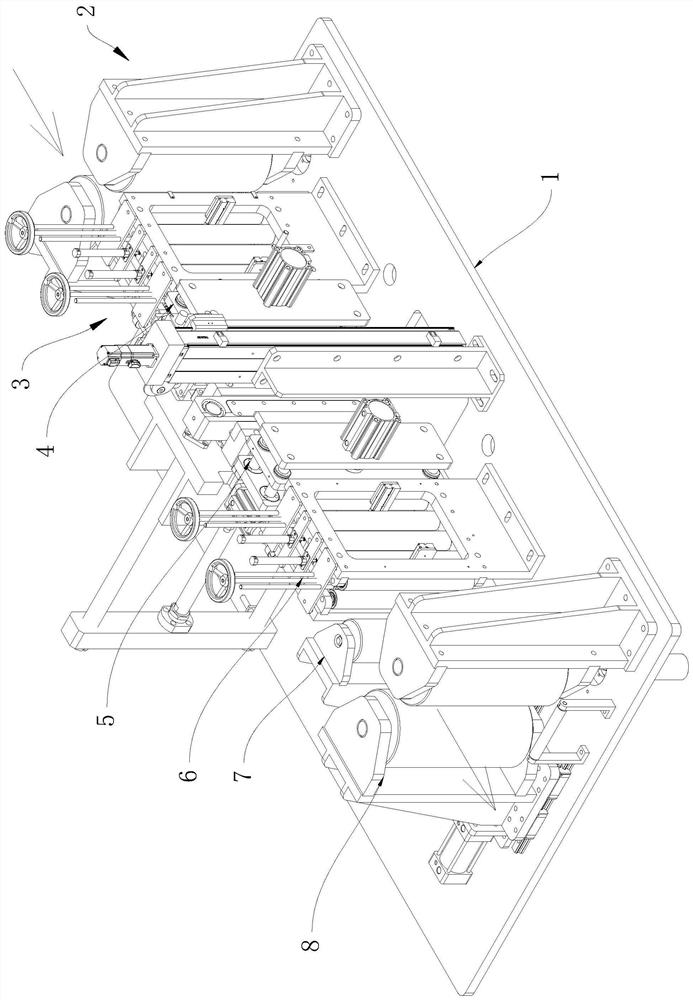

[0022] The invention discloses an on-line shear welding machine for steel strip coils, which combines Figure 1 to Figure 5 As shown, it includes an organic platform 1, and the said platform 1 is provided with:

[0023] A conveying mechanism 2 at the feeding end, which is used to apply a traction force to the rear rolled steel strip in an upright state, and then drive the rear rolled steel strip to be conveyed into the machine 1;

[0024] A feeding end nip roller assembly 3 is located on the output side of the feeding end conveying mechanism 2, and the feeding end nip roller assembly 3 is used for the rear end of the feeding conveying mechanism 2 output side Rolled steel strip exerts preset pressure;

[0025] A feeding end clamping mechanism 4 is located on the output side of the feeding end nip roller assembly 3, and the feeding end clamping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com