Salt slurry elutriation and purification system for evaporation-method salt-nitrate co-production process and salt-nitrate co-production system

A technology of co-production of salt and nitrate and salt slurry, which is applied in the purification of alkali metal sulfite/sulfate, purification of alkali metal halide, alkali metal chloride, etc., can solve the problem that the purity of the finished salt cannot be further purified, and achieve an improvement The purity of the finished salt and the effect of low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

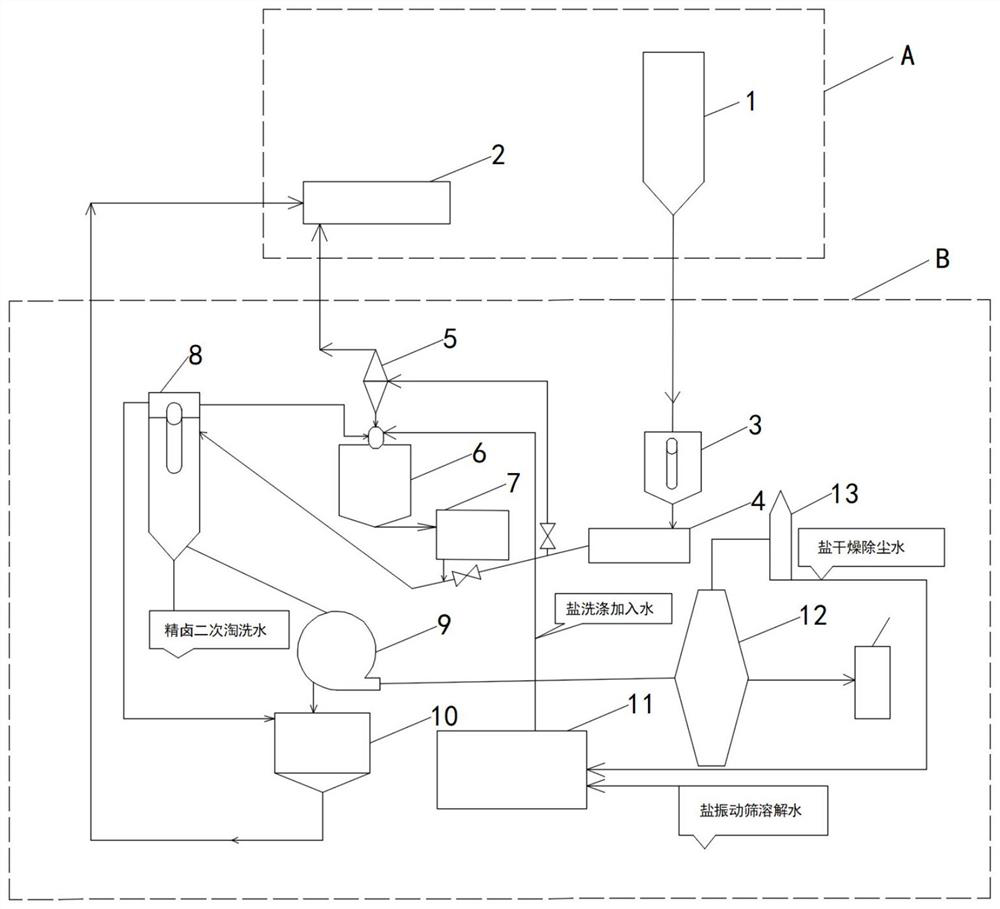

[0029] Such as figure 2 As shown, a salt slurry elutriation and purification system for evaporation salt and nitric acid coproduction process includes a salt discharge buffer tank 3, a first salt slurry pump 4, a cyclone 5, an elutriation salt slurry tank 6, and a second salt slurry Pump 7, elutriation overflow thickener 8, salt centrifuge 9 and salt drying device 12; salt discharge buffer tank 3 buffers and stores the salt slurry discharged from the salt discharge foot 1 of the salt group tank; the first salt slurry pump 4 discharges The salt slurry in the salt buffer tank 3 is pumped to the cyclone 5; the cyclone 5 separates the salt slurry to obtain salt crystals and salt liquid with high solid content; the salt crystals and the elutriation overflow thickener 8 overflow out The refined brine is mixed and elutriated in the elutriation salt slurry tank 6; the second salt slurry pump 7 pumps the salt slurry obtained by mixing and elutriating in the elutriation salt slurry tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com