Electrolytic manganese residue ceramic, preparation method thereof and ceramic tile

An electrolytic manganese slag ceramic and electrolytic manganese slag technology, applied in the field of ceramics, can solve the problems of a large amount of electrolytic manganese slag, human and biological hazards, pollution of the atmosphere, etc., and achieve the effects of being conducive to environmental pressure, improving efficiency, and having significant effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In another aspect of the present invention, the present invention provides a method for preparing the aforementioned electrolytic manganese slag ceramics. The preparation method includes: mixing various raw materials and then performing molding treatment to obtain the electrolytic manganese slag ceramics. Therefore, the operation is simple, convenient and easy to realize.

[0031] In some embodiments of the present invention, the preparation method includes: mixing electrolytic manganese slag, calcined limestone, ceramic waste slag, and fly ash with water before performing the molding treatment.

[0032] In some embodiments of the present invention, based on the total mass of the electrolytic manganese slag, calcined limestone, ceramic waste slag, fly ash and water, the content of the water is 10-20wt% (such as 10wt%, 12wt% , 14wt%, 16wt%, 18wt% or 20wt%, etc.).

[0033] In some preferred embodiments of the present invention, based on the total mass of the electrolytic...

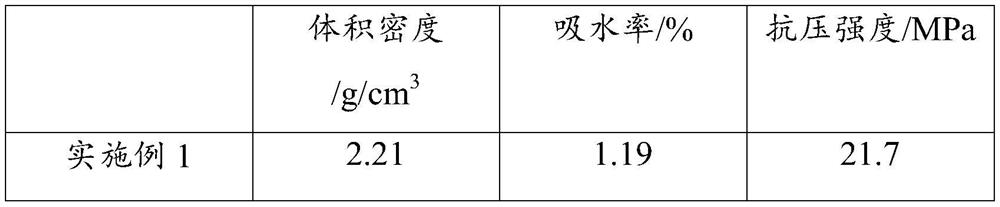

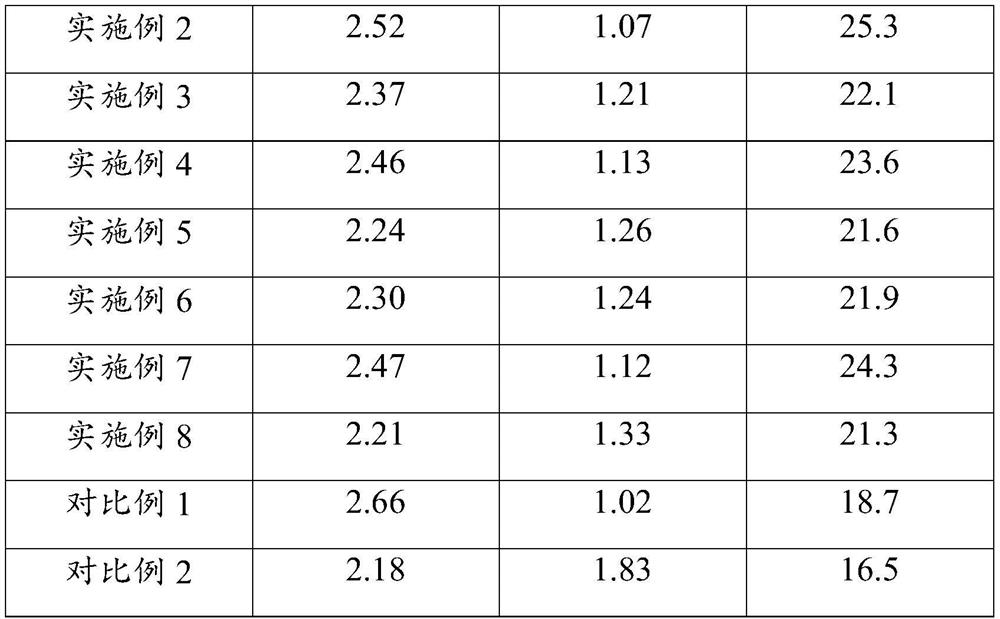

Embodiment 1

[0052] Electrolytic manganese slag ceramics, in parts by mass, are mainly prepared from the following raw materials: 40 parts of electrolytic manganese slag, 15 parts of calcined limestone, 30 parts of ceramic waste slag, and 15 parts of fly ash. The particle sizes of manganese slag, calcined limestone, ceramic waste slag and fly ash are each independently 70 mesh.

Embodiment 2

[0054] Electrolytic manganese slag ceramics, in parts by mass, are mainly prepared from the following raw materials: 50 parts of electrolytic manganese slag, 15 parts of calcined limestone, 30 parts of ceramic waste, 10 parts of fly ash, electrolytic manganese slag, The particle size of calcined limestone, ceramic waste slag and fly ash is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com