Concrete-filled steel tube pile structure and construction method thereof

A technology of steel pipe concrete piles and steel pipe piles, which can be applied to foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of reduced bearing capacity, decreased load capacity, uneven thickness of concrete, etc., and achieve the effect of enhanced bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

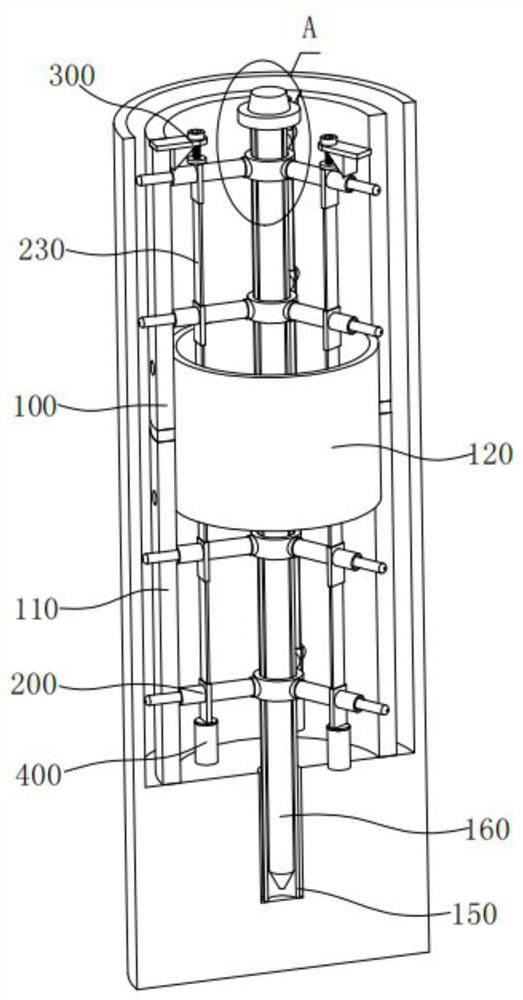

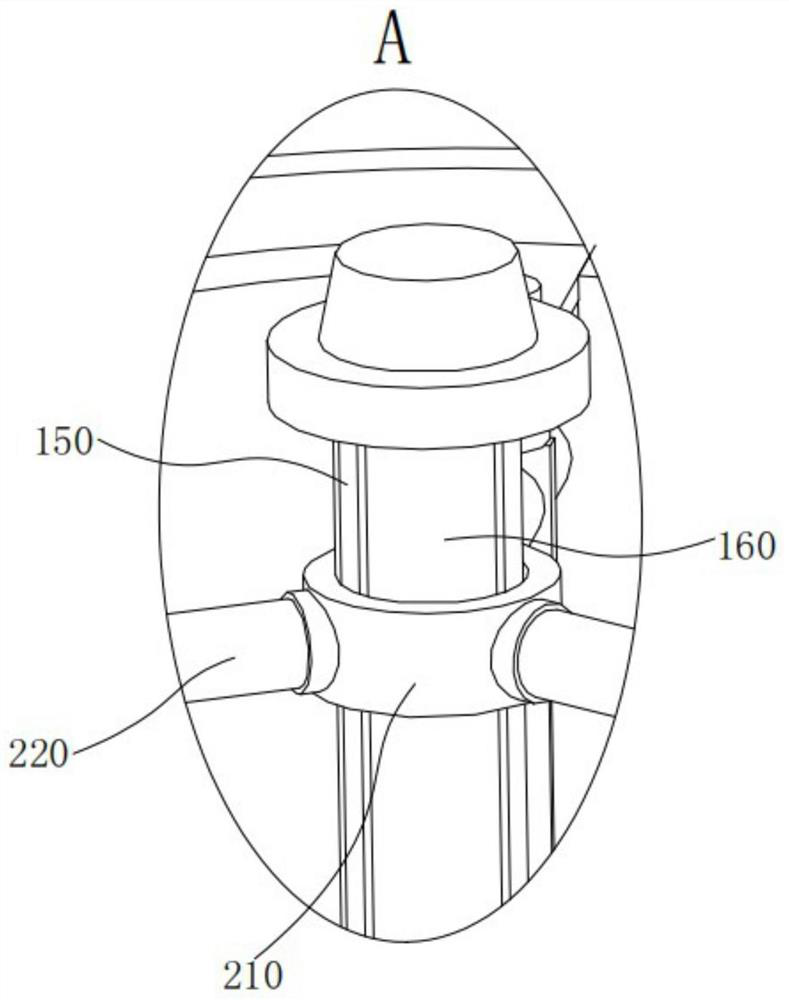

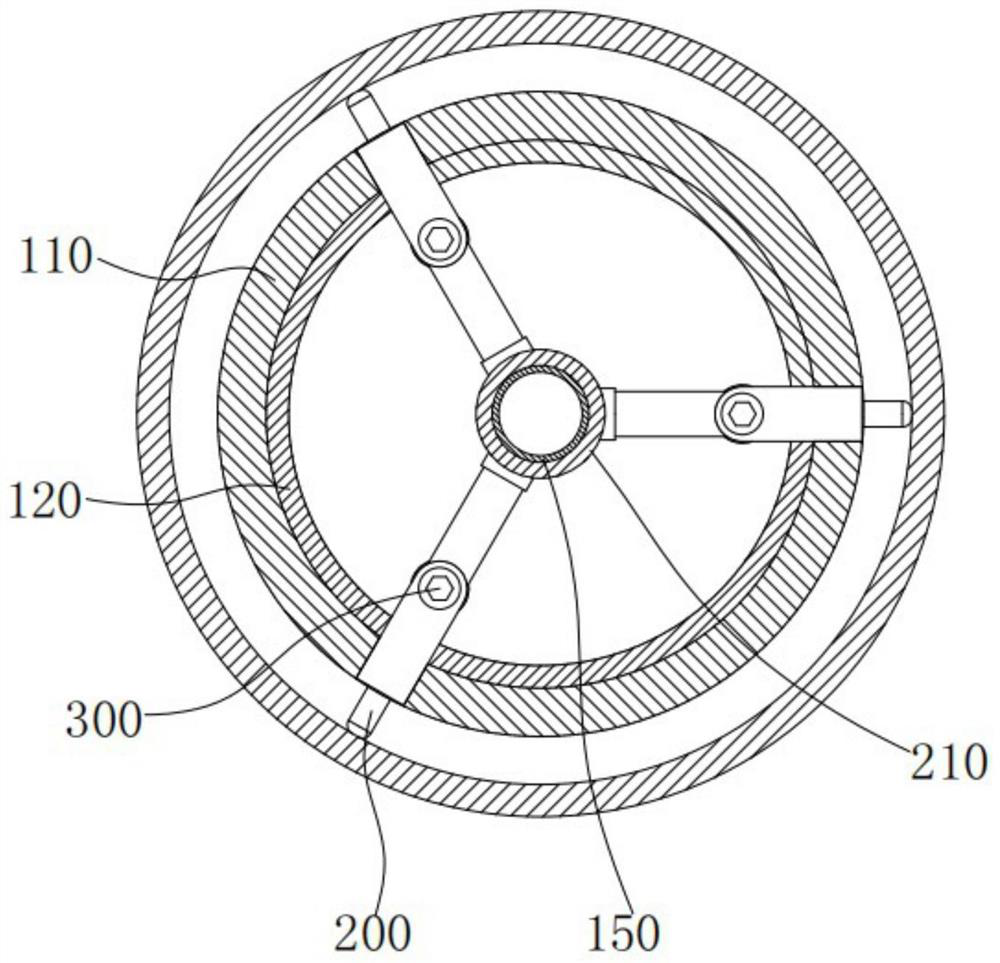

[0047] At present, during the construction of steel pipe concrete piles, a tripod and a locator are usually first laid on the pipe pins of the steel pipe, and then the steel pipe cloth, the tripod and the locator are inserted into the bottom hole at the same time. The steel pipe is positioned, but because the depth of the bottom hole is long, the tripod and the locator are installed at the bottom of the steel pipe. When the steel pipe reaches the bottom of the bottom hole, the tripod and the locator often cannot make the entire steel pipe in the middle of the bottom hole. As a result, the steel pipe is installed eccentrically in the bottom hole, which leads to the uneven thickness of the concrete poured between the bottom hole and the steel pipe in the later stage, which leads to a significant drop in bearing capacity, and the entire steel pipe is not vertical to the ground, further causing a drop in load capacity.

[0048] In order to make up for the above deficiencies, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com