Self-repairing concrete, prefabricated embedded column core concrete composite column and preparation method

A concrete and self-healing technology, applied in the field of composite columns, can solve the problems of insufficient compressive bearing capacity of composite columns, inconvenient construction of composite injection molding, weak self-repairing ability, etc., and achieve concrete with enhanced self-healing efficiency and microbial self-repair The effect of good structural performance and high proportion of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a kind of self-repairing concrete, and self-repairing concrete is microbial self-repairing concrete, and described microbial self-repairing concrete is calculated by volume percentage, is made up of concrete batching, regenerated coarse aggregate carrier and Bacillus pasteurian bacteria liquid; Wherein The volume ratio of the bacterial liquid is converted from the water density value to the mass ratio; the volume ratio of other components is converted to the mass ratio and weighed;

[0049] The volume dosage of the regenerated coarse aggregate carrier is 8% to 12% of the total volume of the microbial self-repairing concrete, and the volume dosage of the Bacillus pasteurian bacteria solution is 30% of the total volume of the microbial self-repairing concrete;

[0050] The concrete batching is composed of sand, stone, cement and water by volume percentage, sand: stone: cement: water=(3.10~3.30):(1.55~1.80):(1.00~1.25):(0.50~0.65 );

[0051] The O...

Embodiment 2

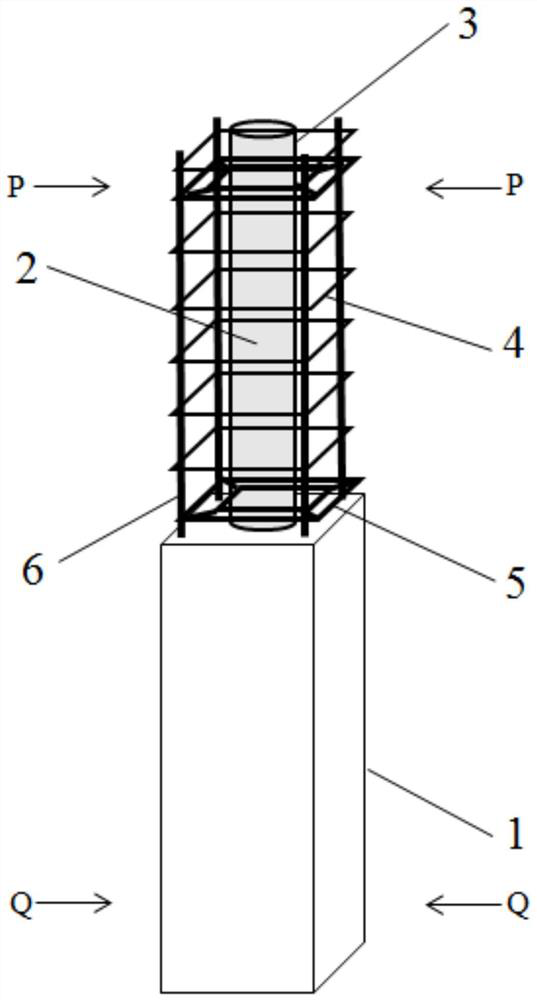

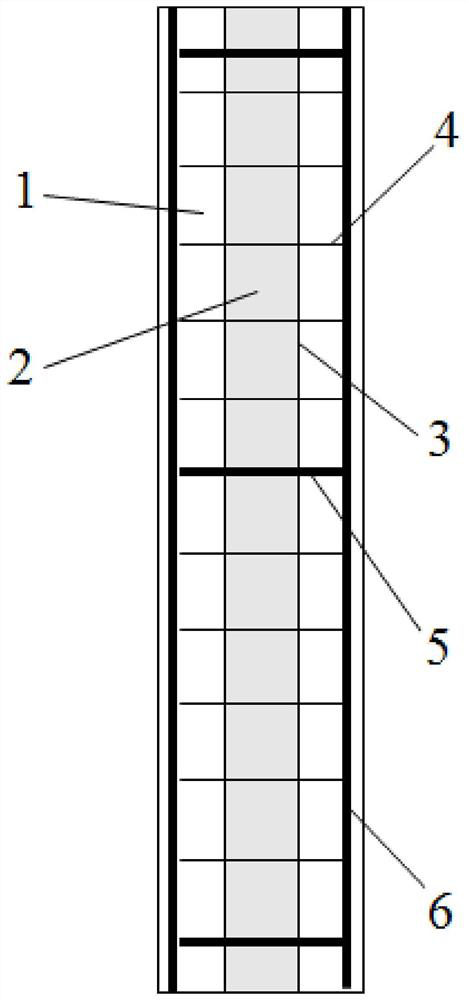

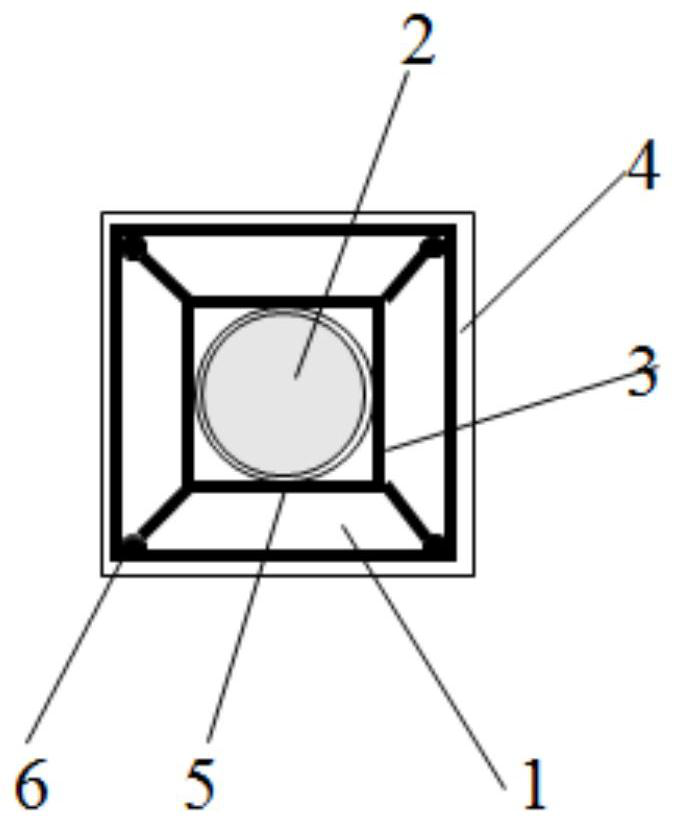

[0077] Same as embodiment 1, the difference from embodiment 1 is that this embodiment provides the setting method of the self-repairing concrete part 1 of the concrete composite column subjected to eccentric compressive stress.

[0078] Composite columns appear as Figure 5 The cracking form shown in (b) is specially adopted for its cracking form as follows Figure 6 In the pouring method shown in the shaded part in (b), the distances from the central axis of the circular steel pipe 3 to the two opposite surfaces of the composite column are 77-83mm and 217-223mm respectively, and the distances from the other two opposite surfaces of the composite column are equal 150mm. Microbial self-healing concrete was poured on the eccentrically compressed part of the composite column and on the side where transverse cracks appeared. After loading to 1000KN, a large number of cracks have appeared in the concrete. The width of the cracks measured by the crack observer is approximately 0....

Embodiment 3

[0083] Same as embodiment 1, the difference from embodiment 1 is that this embodiment provides the setting method of the self-repairing concrete part 1 of the concrete composite column under the loading mode of horizontal load.

[0084] Composite columns appear as Figure 5 The cracking form shown in (c) is specially adopted for its cracking form as follows Figure 6 The pouring method shown in the shaded part in (c) is that microbial concrete is poured on the side that does not directly bear the horizontal load, the outer wall of the circular steel pipe 3 fits with the center of the plane on the side where the longitudinal reinforcement is poured, and the center-axisbase composite column of the circular steel pipe 3 The distance from the surface is 227-233mm, and the distance from the other two opposite surfaces of the combined column is 150mm. When the horizontal load was increased to 400KN, a large number of oblique cracks appeared in the concrete, and the crack width was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com