Waste heat recovery device for air compressor

A technology of waste heat recovery device and air compressor, which is applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc. It can solve the problems of high-temperature steam heat loss, loose clamping block device, ground depression, etc. Leakage, realize waste heat recovery and utilization, and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

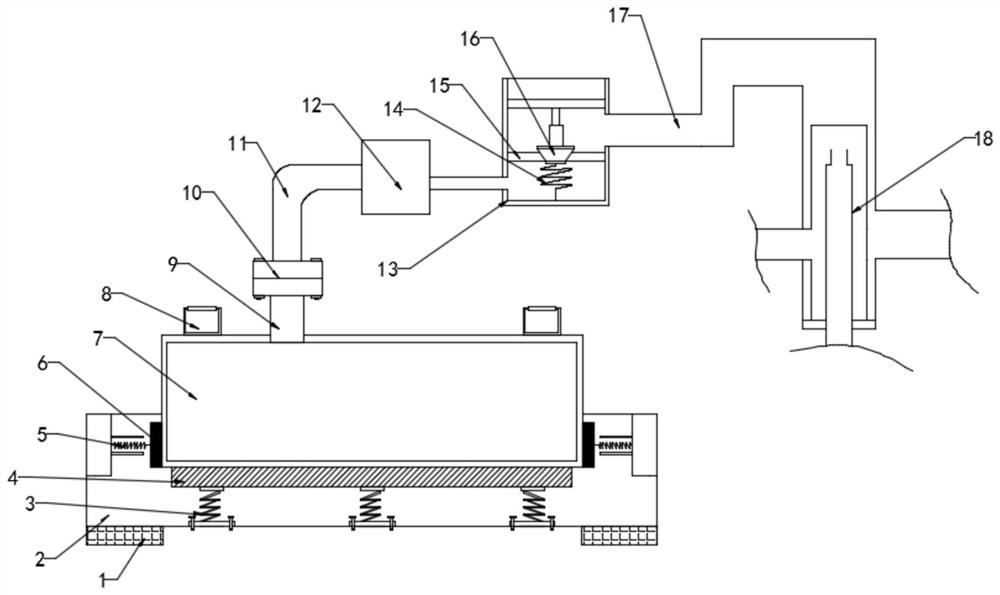

[0022] see figure 1 , in Embodiment 1 of the present invention, an air compressor waste heat recovery device, which includes: a mounting seat 2 and an air compressor body 7, seat cushions 1 are provided on the left and right sides of the lower end of the mounting seat 2, and the seat cushion 1 is raised The stability of the air compressor waste heat recovery device when it is placed; the installation seat 2 is provided with a buffer assembly, and the air compressor body 7 is placed on the buffer assembly inside the installation seat 2, and the air compressor body 7 is supported by the buffer assembly. Shock absorption during operation;

[0023] The upper end of the air compressor body 7 is connected to the main outlet pipe 9, and the upper end of the main outlet pipe 9 is connected to the suction fan 12 through the cooperation of the connection assembly 10 and the suction pipe 11, and one end of the suction fan 12 is connected to the temporary storage box 13, An air outlet co...

Embodiment 2

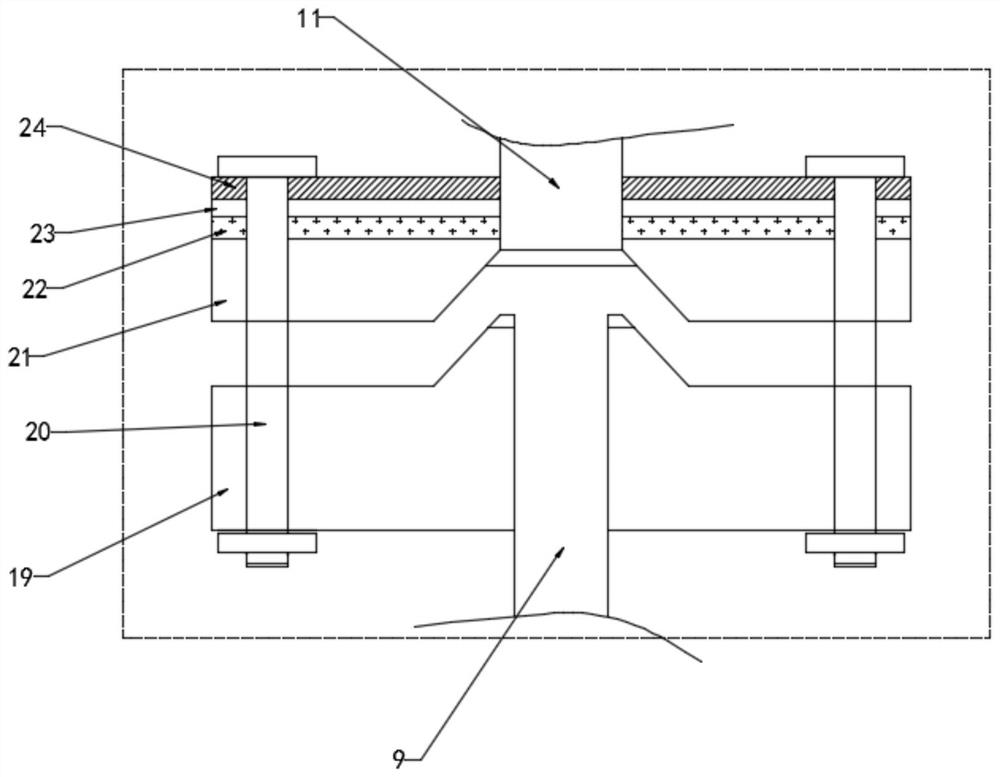

[0029] see figure 2 , further, the connection assembly 10 includes a first flange 19 and a second flange 21, and the first flange 19 and the second flange 21 are connected by bolts 20;

[0030] Specifically, a channel is provided inside the first flange 19, the lower end of the channel inside the first flange 19 is connected to the main steam outlet pipe 9, and a protrusion is provided on the upper end of the first flange 19; the second flange 21 There is a channel inside, the upper end of the channel inside the second flange 21 is connected to the suction pipe 11, and the lower end of the second flange 21 is provided with a groove; when the first flange 19 and the second flange 21 are assembled, the first method The protrusion at the upper end of the flange 19 is placed inside the groove at the lower end of the second flange 21, so that the main outlet pipe 9, the passage inside the first flange 19, the passage inside the second flange 21 and the suction pipe 11 are connecte...

Embodiment 3

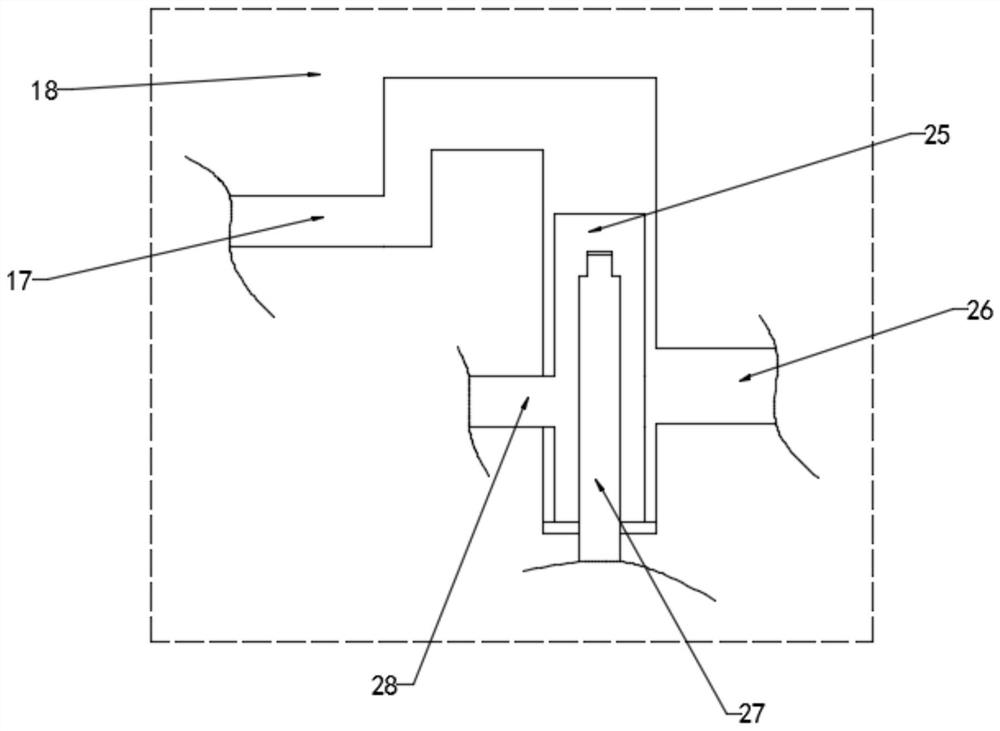

[0034] Further, the air outlet assembly includes a movable plug 16, a partition 15 is arranged inside the temporary storage box 13, and the partition 15 divides the inside of the temporary storage box 13 into two cavities, the upper and lower cavities are passed through the partition The channel provided on 15 is connected, and a movable plug 16 is installed in the channel;

[0035] Specifically, the lower end of the movable plug 16 is connected to the inner wall of the bottom end of the cavity through the third compression spring 14, and the upper end of the movable plug 16 is sleeved and movably installed on the sleeve rod provided in the cavity;

[0036] When starting the suction fan 12, the suction fan 12 makes the high-temperature steam entering the temporary storage box 13 have pressure, pushes the movable plug 16 to move upwards, opens the passage on the partition plate 15, and makes the steam output; when the suction fan 12 stops During operation, the high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com