Miniaturized MEMS (Micro Electro Mechanical System) capacitive composite resonance type vector hydrophone

A vector hydrophone, capacitive technology, applied in instruments, measuring devices, electrical devices, etc., can solve problems such as lack of scalar sound pressure detection capability, inability to accurately obtain sound field information, and complex suspension structure, to ensure the acquisition of Integrity and accuracy, simplicity of construction, effect of reducing size and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

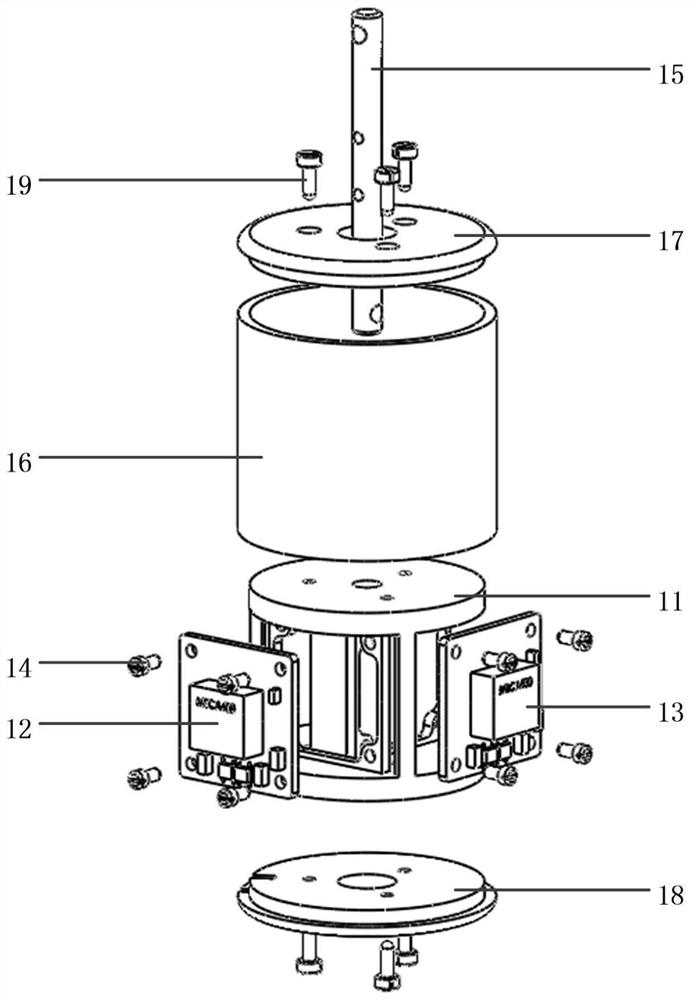

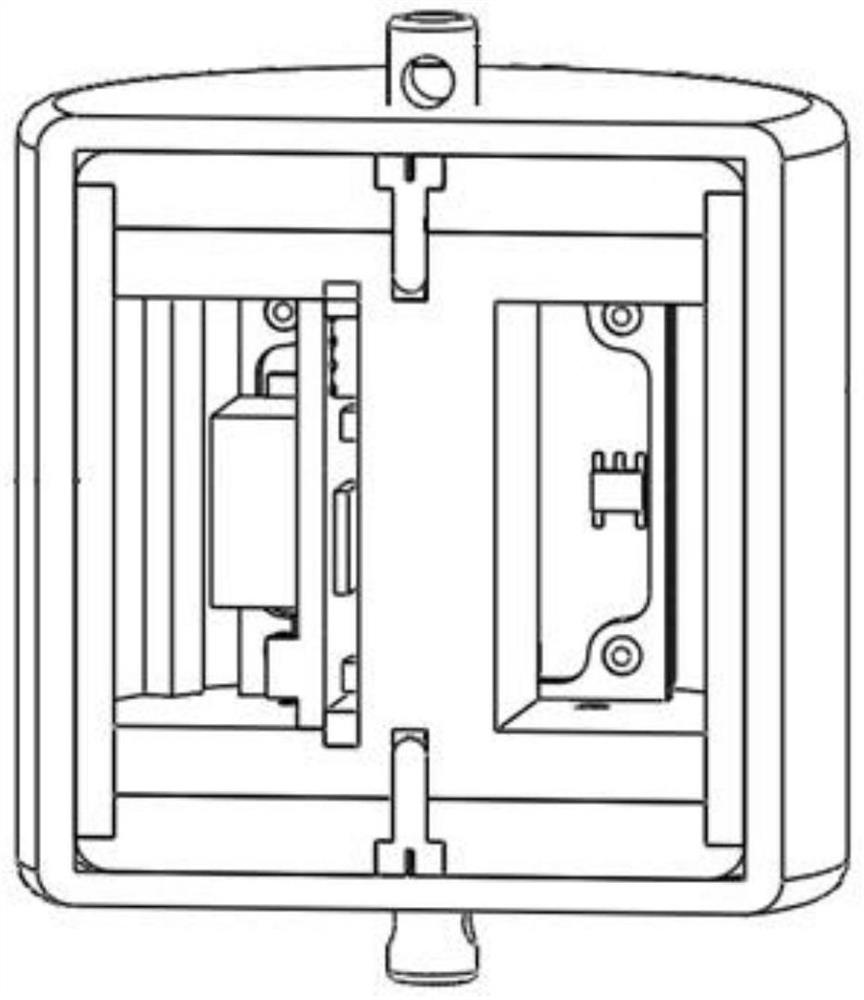

[0026] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

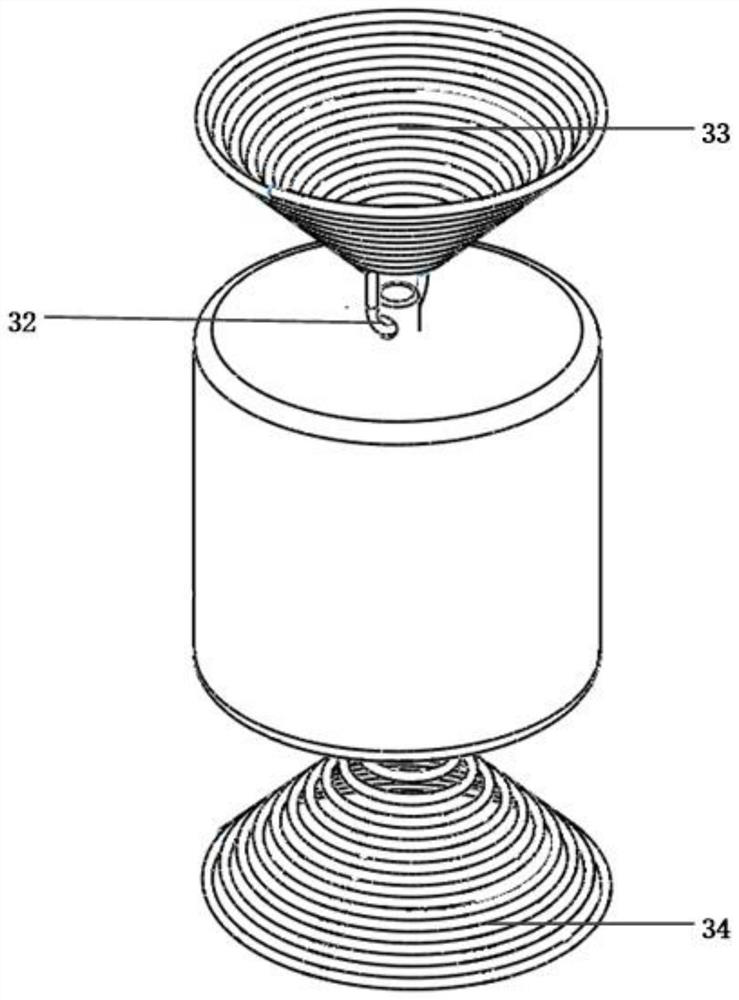

[0027] The theoretical basis of scalar signal detection is: when the piezoelectric ceramic ring acts in the sound field, it can receive the acoustic signal excitation from the water medium, force the piezoelectric material to produce forced vibration and deformation, and induce the charge, thereby converting the vibration signal It is an electrical signal output to realize scalar detection of acoustic signals.

[0028] The theoretical basis of vector signal detection is: if the geometric size of the acoustically rigid body is smaller than the wavelength, then when it vibrates freely under the action of sound waves in water, the vibration velocity amplitude V of the rigid cylinder is related to the geometry of the cylinder in the sound field. Vibration velocity amplitude V of the water particle at the center of gravity 0 The following relation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com