A method for realizing no mode hopping in semiconductor laser chip wave locking

A technology of lasers and semiconductors, which is applied in the field of fiber lasers and semiconductors, can solve problems such as inability to lock waves and jump membranes, and achieve the effects of solving membrane jumps, eliminating stress, and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

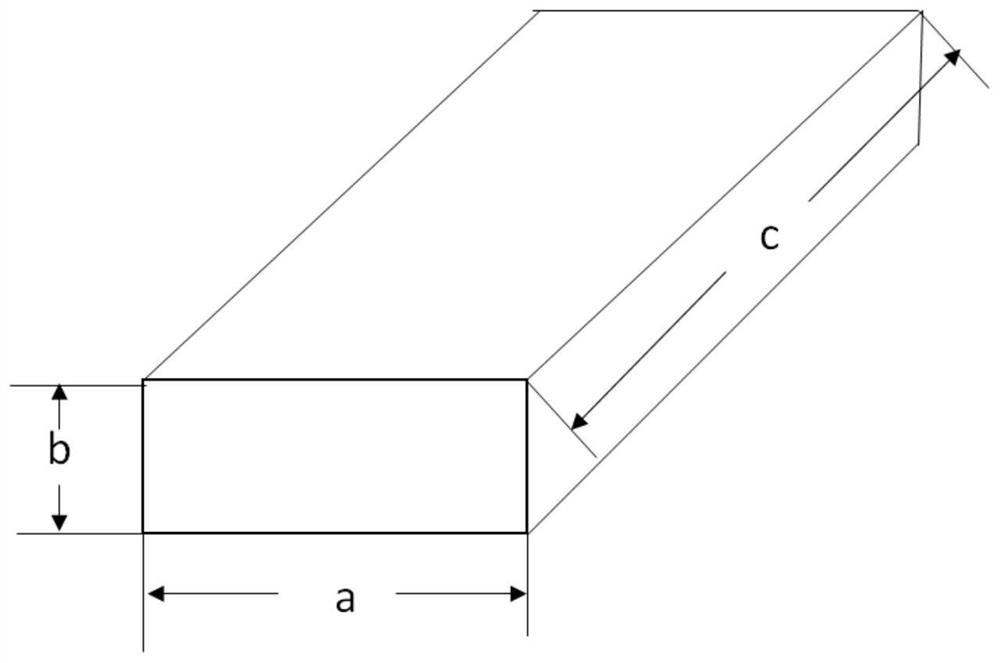

[0042] Such as image 3 As shown, the auxiliary heat sink is a cuboid (a×b×c), such as Figure 4 As shown, the groove design is performed on the surface of COS mounting (the upper surface composed of side a and side c), the groove is a linear groove, and the direction of the groove is parallel to side a.

Embodiment 2

[0044] Such as Figure 5 As shown, the groove is designed on the surface of COS mounting (the upper surface composed of side a and side c). The groove is a linear groove, and the direction of the groove is parallel to side c.

Embodiment 3

[0046] Such as Figure 6 As shown, the groove design is carried out on the surface of COS mounting (the upper surface composed of side a and side c). The groove is a linear groove, and the direction of the groove is parallel to sides a and c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com