Patents

Literature

59results about How to "Optimizing Spectrum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Channel frequency allocation for multiple-satellite communication network

InactiveUS6021309AReduce decreaseImprove availabilityNetwork traffic/resource managementNetwork topologiesTelecommunicationsSatellite

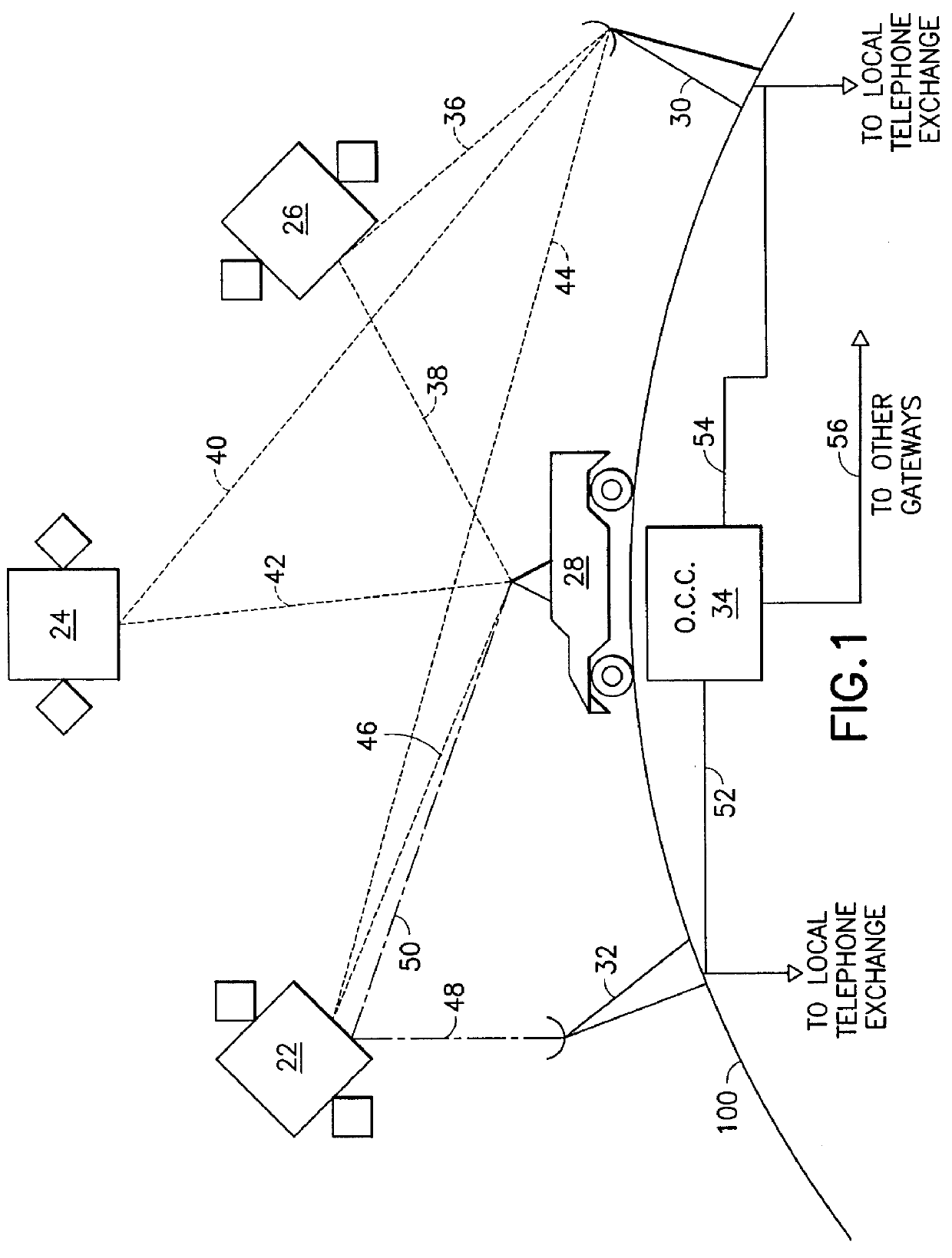

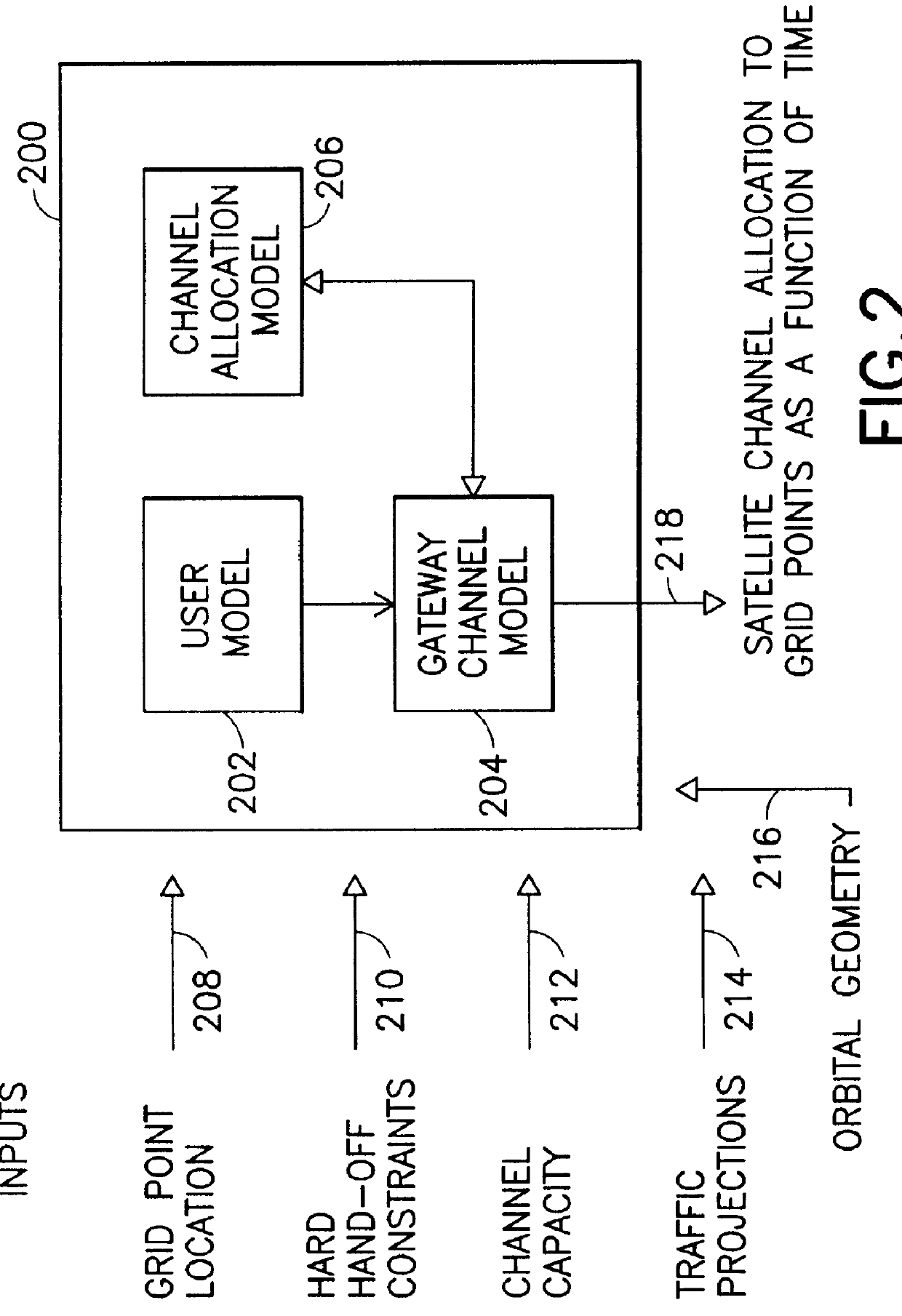

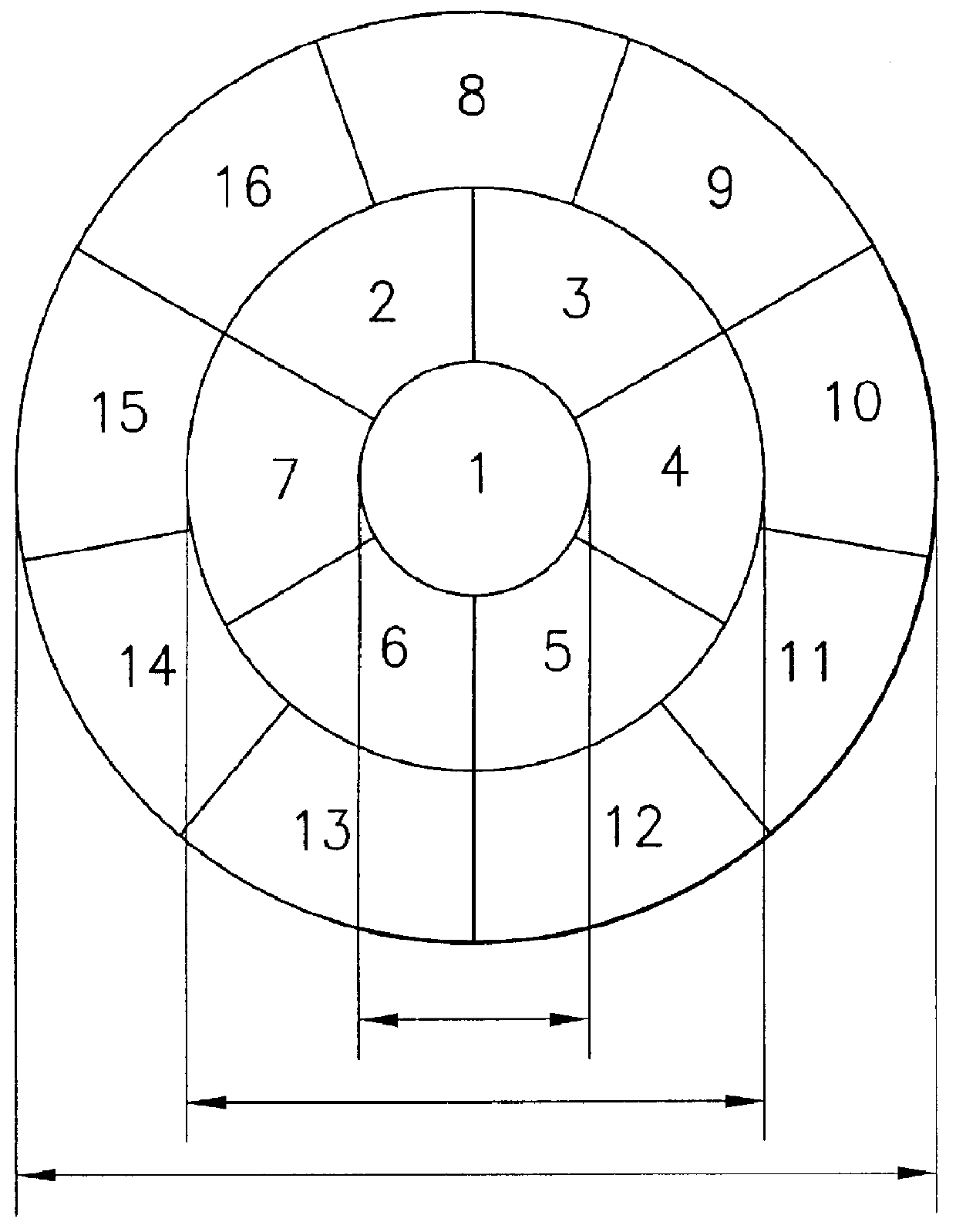

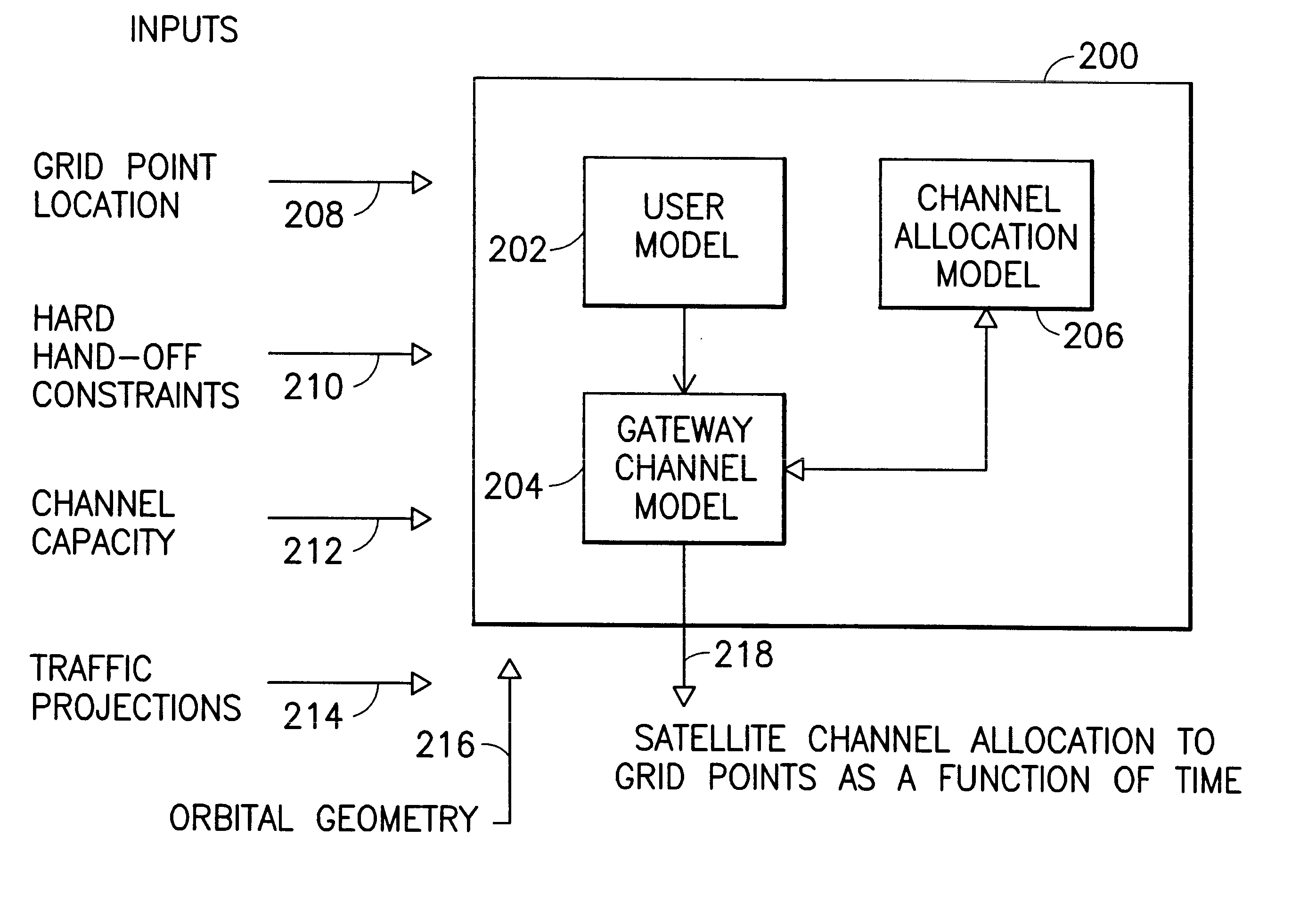

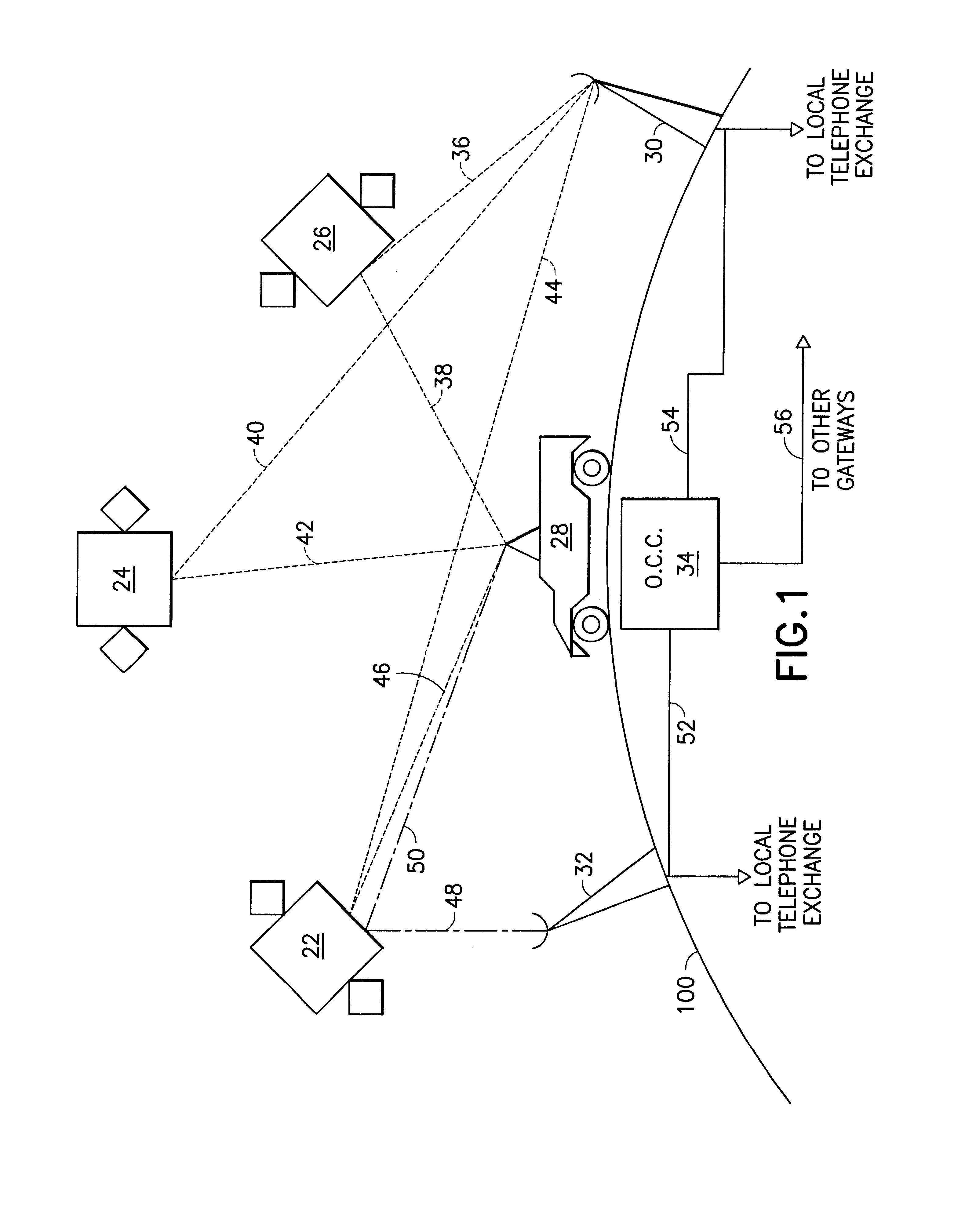

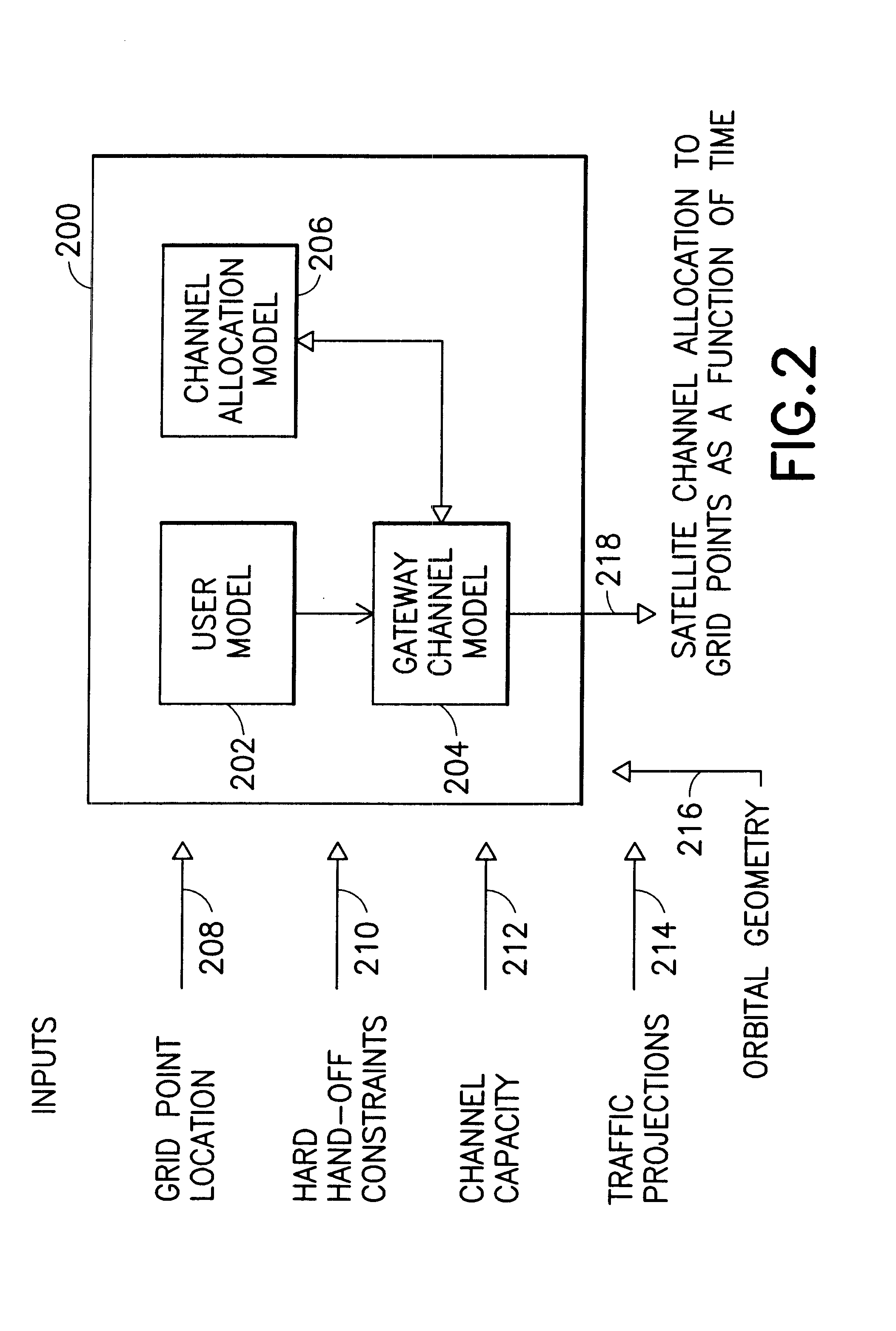

A method and apparatus (system) for providing forward-link channel-frequency allocation for multiple-satellite cellular communications networks is disclosed. The system has a centralized ground-operations control center that provides bi-weekly minute-by-minute allocation plans for geographically-defined service areas. This enables each service area to set its diversity policy in accordance with the requirements of the government regulators and customer preferences within the service area. The system has a user model having a frequency re-use pattern, a channel allocation model for modelling the power allocated to each channel, and a gateway channel model for allocating channels in accordance with the user model and the channel allocation model. The allocation is made for each satellite of the plurality of satellites. The traffic allocation induces an operating frequency for each of the one or more links in each satellite of the plurality of satellites. The satellite communication system computed frequency allocation is optimized to minimize total radiation from all forward links for one or more of the plurality of satellites.

Owner:GLOBALSTAR INC +1

Channel frequency allocation for multiple-satellite communication network

InactiveUS6463279B1Reduce decreaseImprove availabilityNetwork topologiesActive radio relay systemsTelecommunicationsTraffic allocation

A method and apparatus (system) for providing forward-link channel-frequency allocation for multiple-satellite cellular communications networks is disclosed. The system has a centralized ground-operations control center that provides bi-weekly minute-by-minute allocation plans for geographically-defined service areas. This enables each service area to set its diversity policy in accordance with the requirements of the government regulators and customer preferences within the service area. The system has a user model having a frequency re-use pattern, a channel allocation model for modelling the power allocated to each channel, and a gateway channel model for allocating channels in accordance with the user model and the channel allocation model. The allocation is made for each satellite of the plurality of satellites. The traffic allocation induces an operating frequency for each of the one or more links in each satellite of the plurality of satellites. The satellite communication system computed frequency allocation is optimized to minimize total radiation from all forward links for one or more of the plurality of satellites.

Owner:GLOBALSTAR INC +1

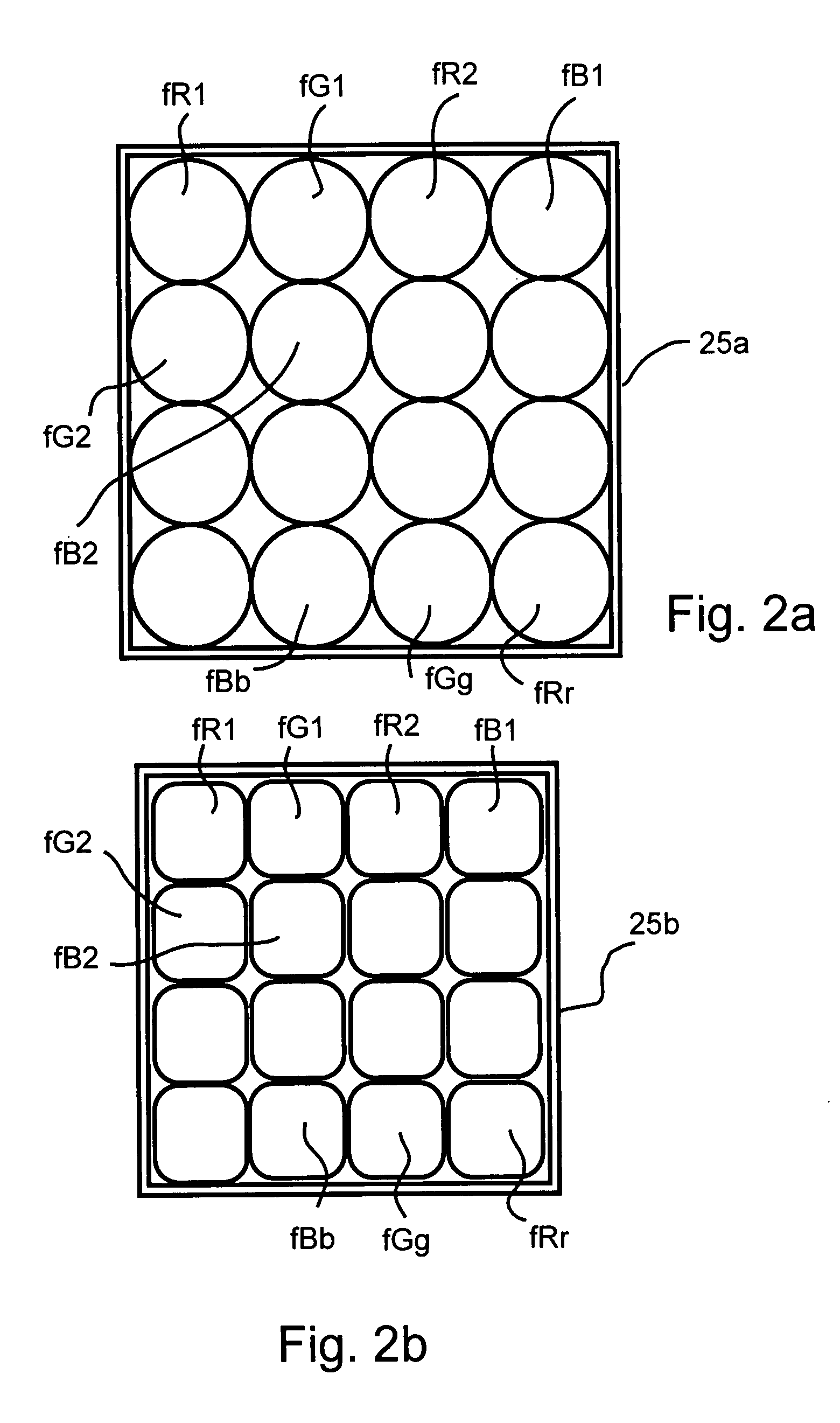

Brightness with reduced optical losses

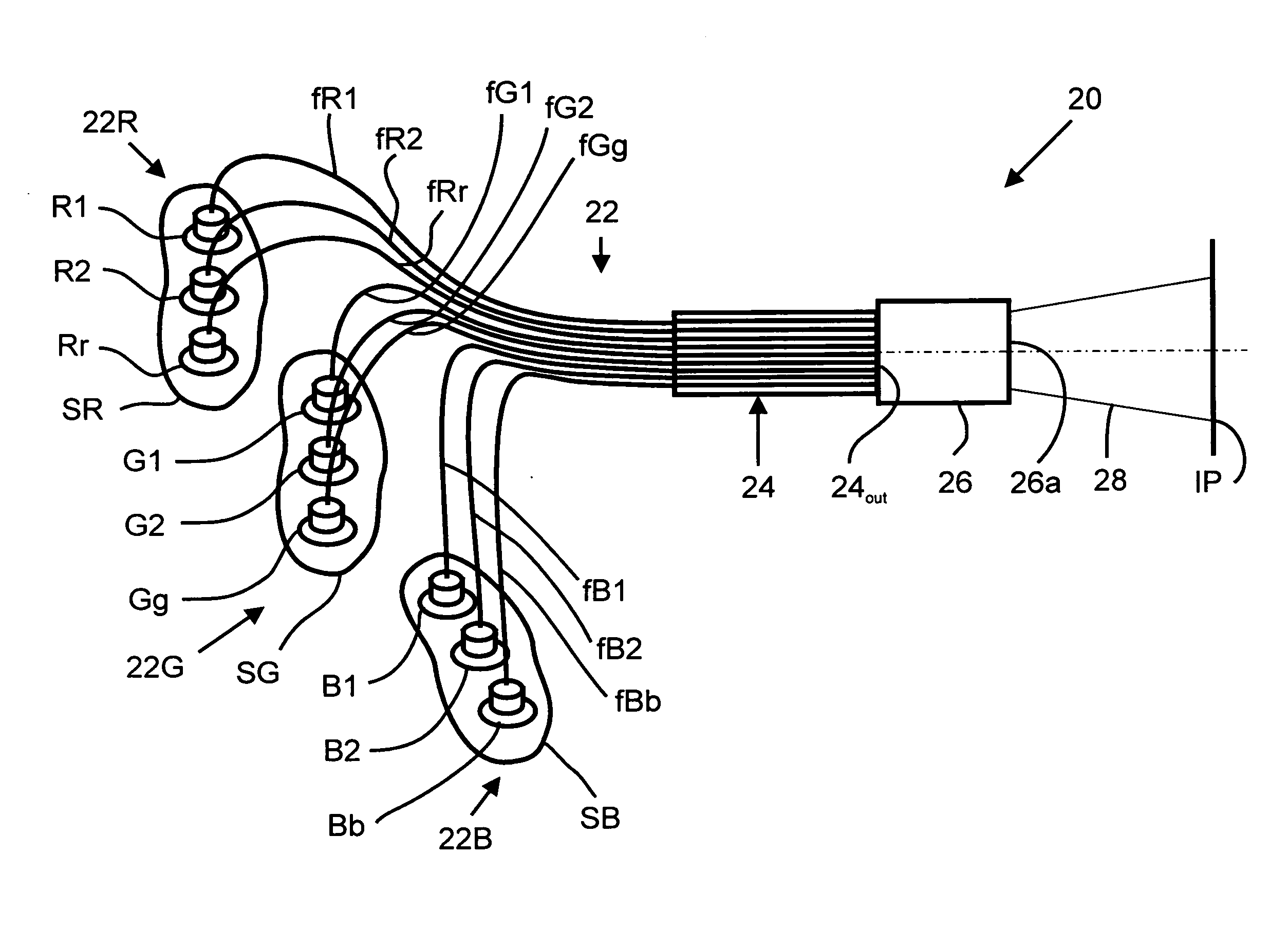

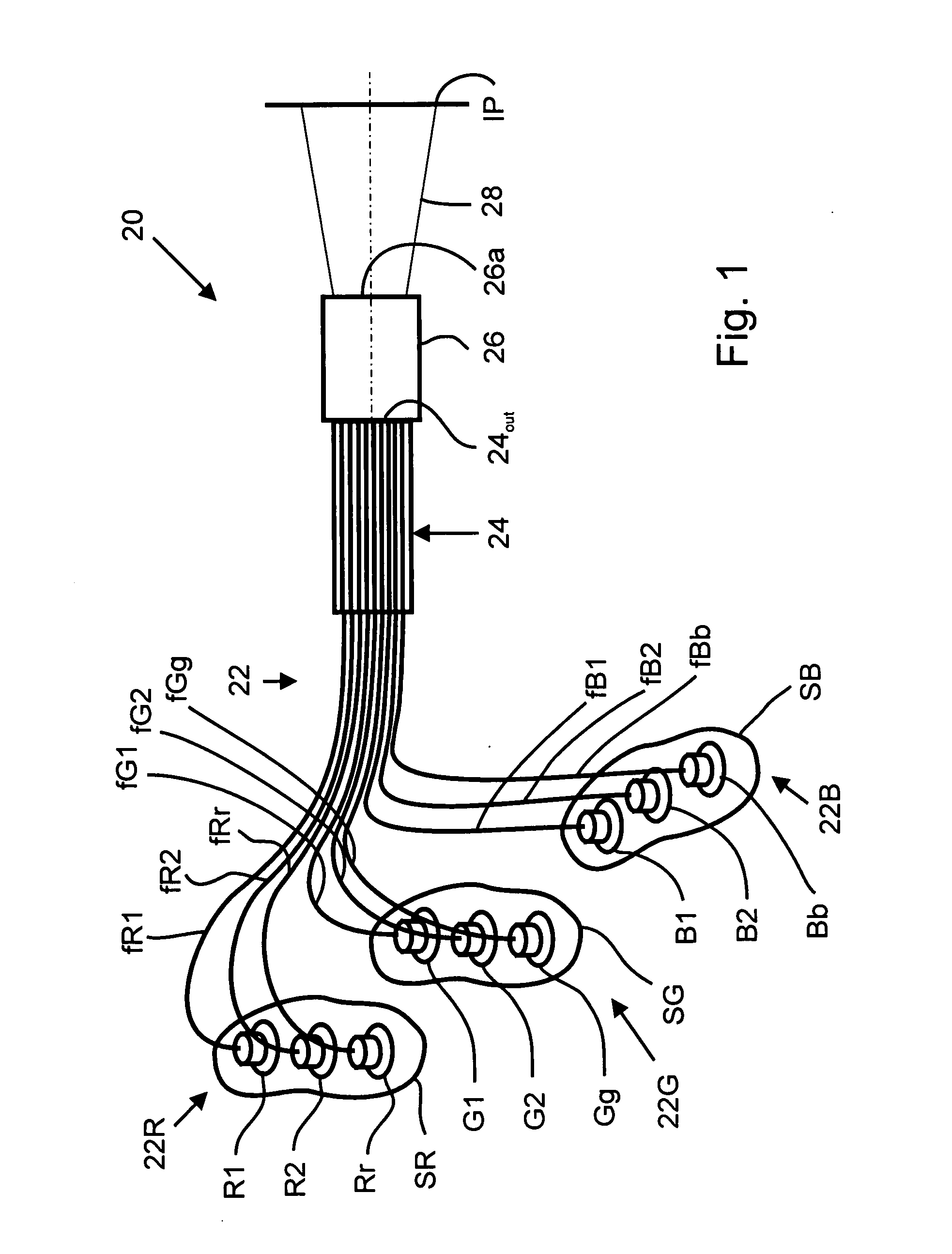

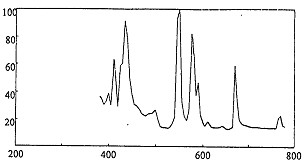

InactiveUS20080310181A1Optimizing SpectrumIncrease brightnessEndoscopesFibre light guidesOptoelectronicsEndoscopic camera

A fiber-bundle illumination system of high brightness with reduced optical losses comprises a plurality of light sources that emit lights of different colors and transmit the component lights of different colors to a light mixer through individual optical-fiber light guides assembled into a bundle, which is crimped at least at the inlet and outlet ends. Unique features of the system are optical coupling between the light sources and their respective light guides and mixing colors in a predetermined proportion that results in spatially uniform distribution of the spectrum on the illuminated area. The system may be used in conjunction with optical instruments such as endoscopic cameras, microscopes, etc.

Owner:MICROALIGN TECH

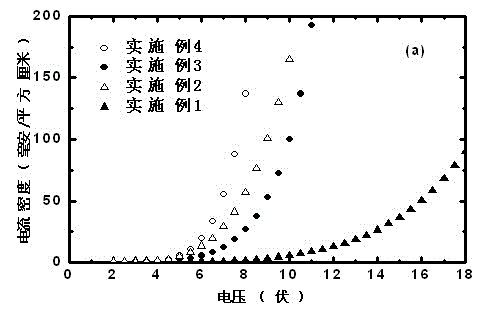

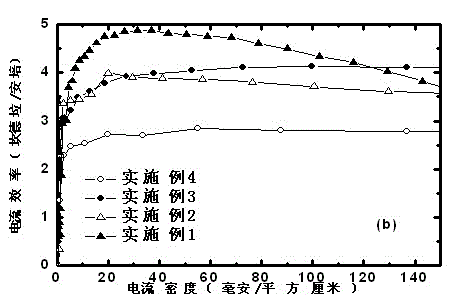

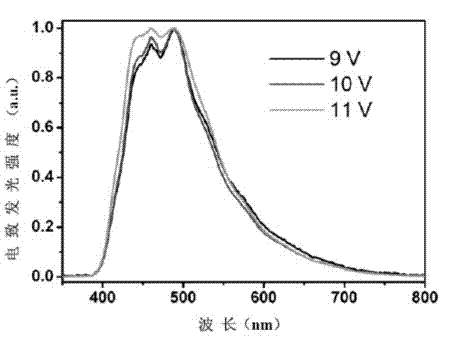

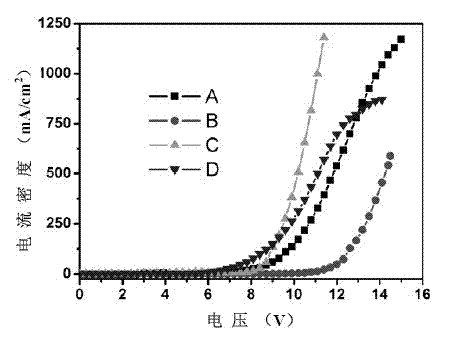

High-efficiency organic light-emitting diode and fabrication method thereof

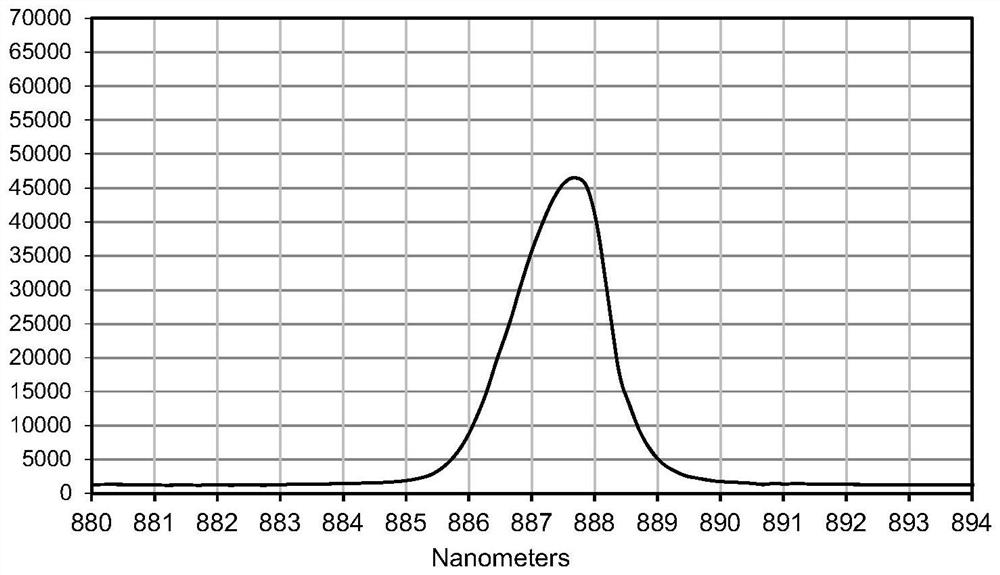

InactiveCN102983285AOptimizing SpectrumDecrease spectral width at half maximumSolid-state devicesSemiconductor/solid-state device manufacturingMetallic electrodeLight-emitting diode

The invention relates to a high-efficiency organic light-emitting diode and a fabrication method of the light-emitting diode. The high-efficiency organic light-emitting diode is fabricated by a microcavity effect and a surface plasma emission method. More particularly, a DBR (Distributed Bragg Reflector) coupling layer is used for generating a microcavity effect, and the method of plasma emission on the surface of a metal electrode is used for achieving the high-efficiency organic light-emitting diode. The high-efficiency organic light-emitting diode is fabricated by the DBR coupling layer and the method of the plasma emission on the surface of the metal electrode, and comprises a substrate, a composite anode, a hole injection layer, a hole transport layer, a luminous layer, an electron transport layer, an electron injection layer and a cathode, or comprises a substrate, a composite cathode, an electron injection layer, an electron transport layer, a luminous layer, a hole transport layer, a hole injection layer and an anode sequentially from the bottom up.

Owner:NANJING UNIV OF POSTS & TELECOMM

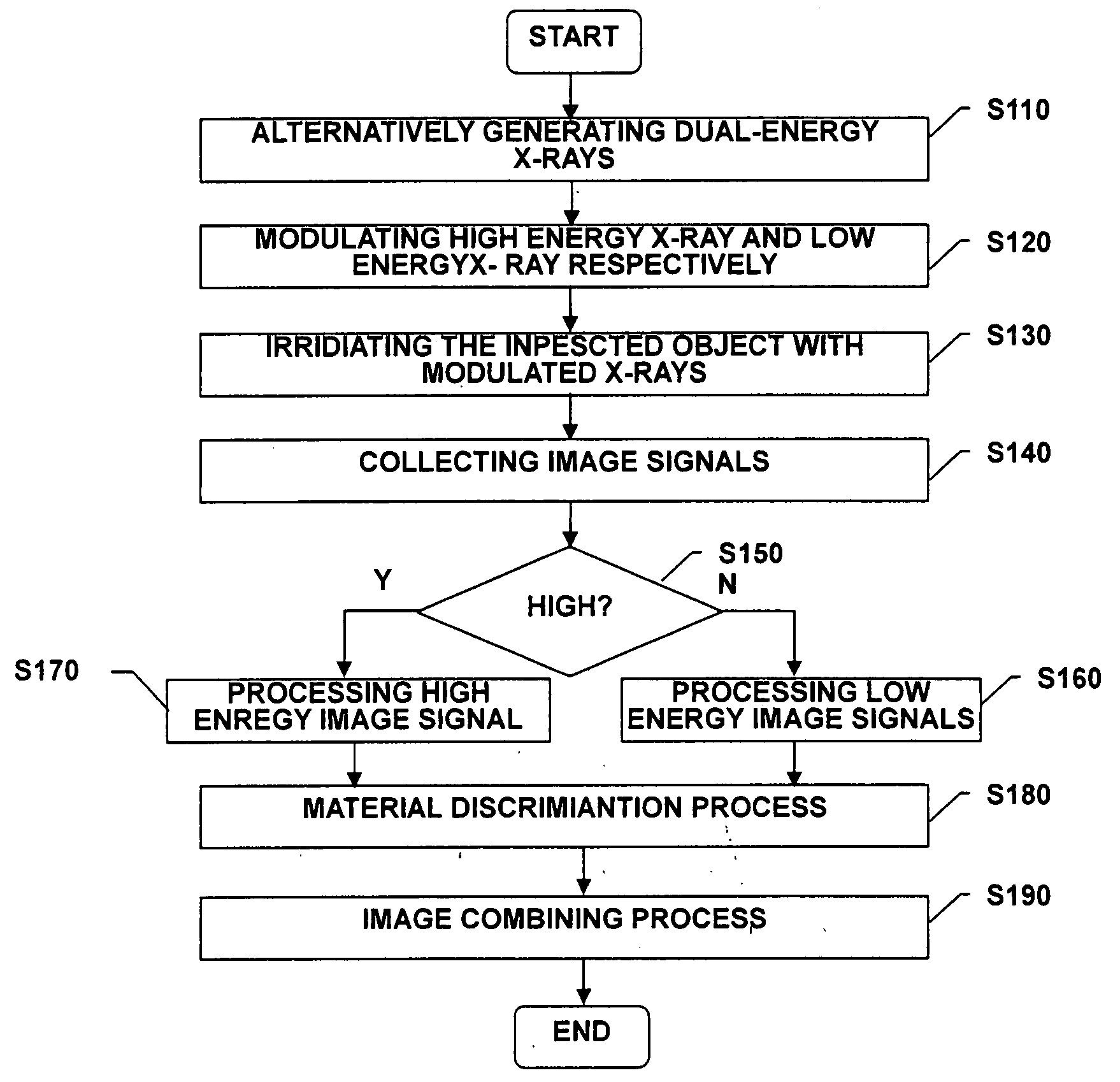

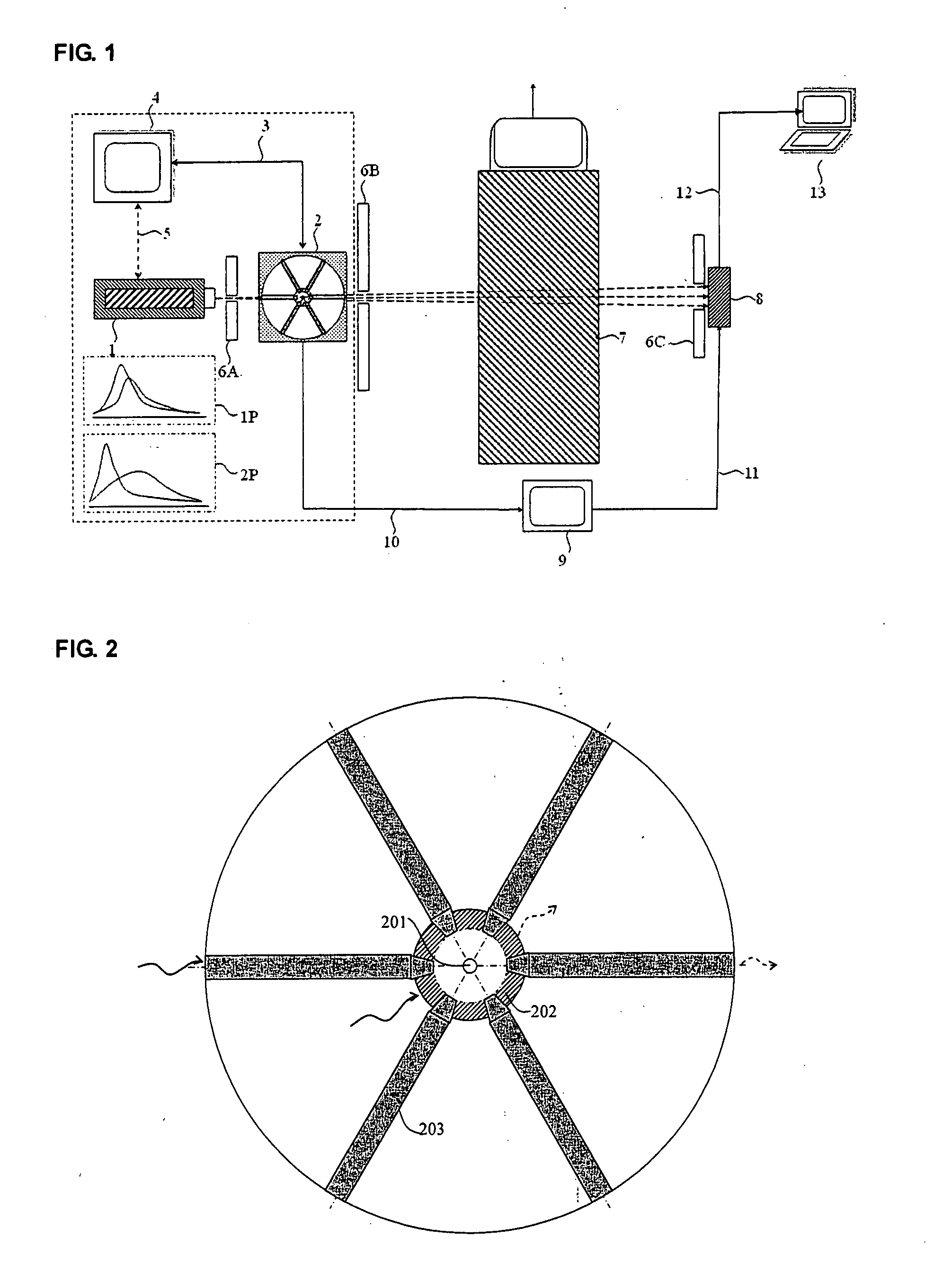

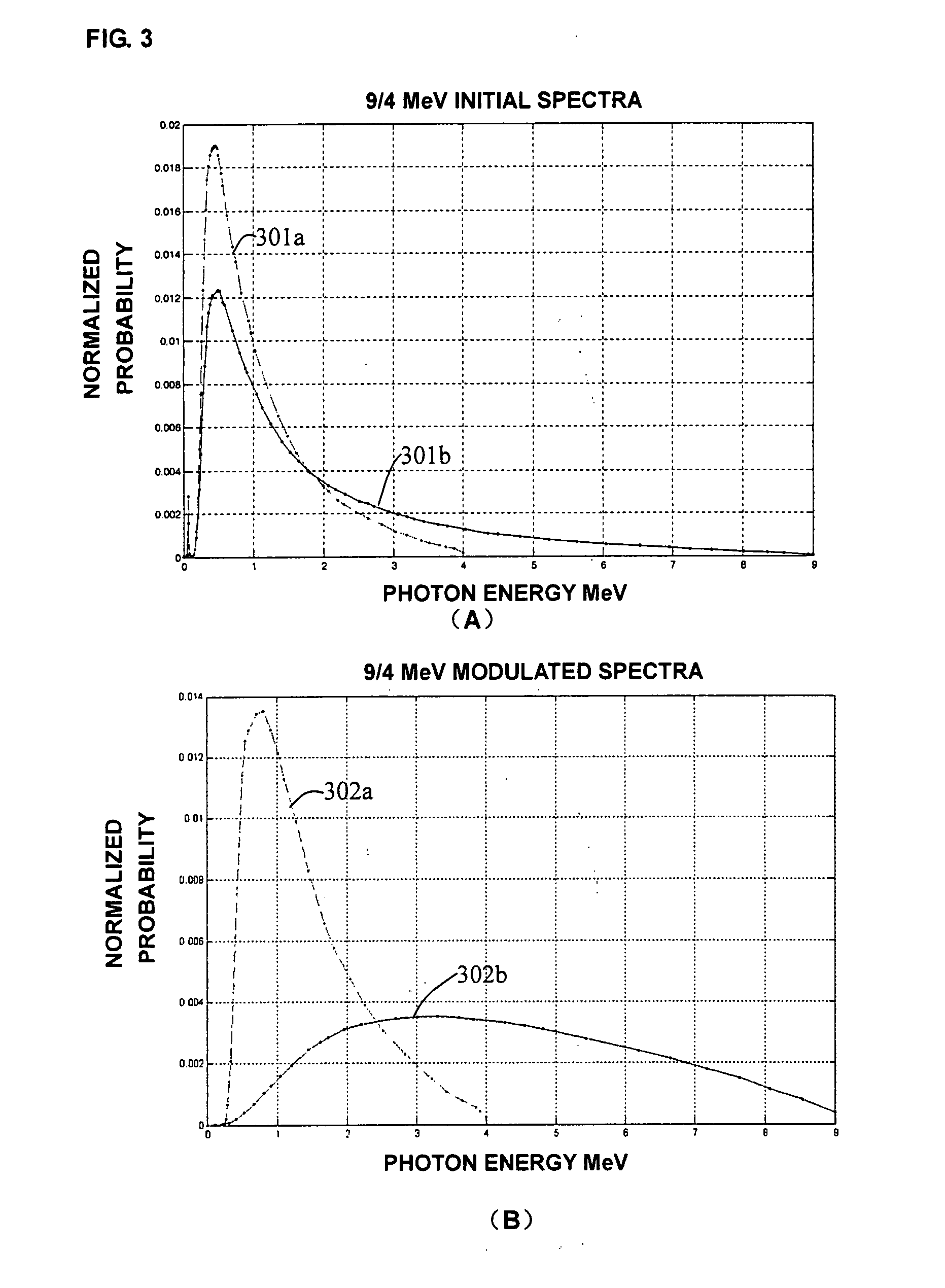

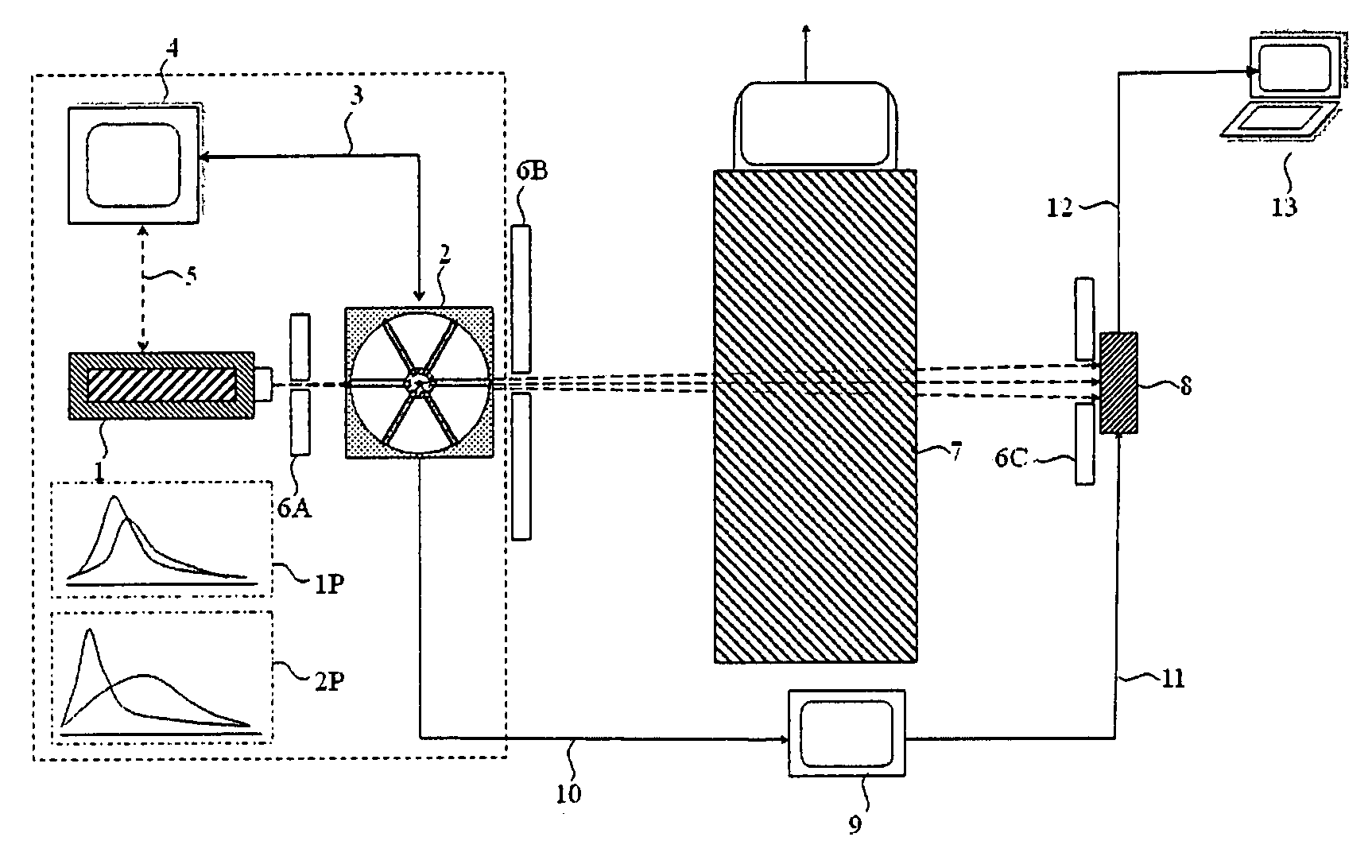

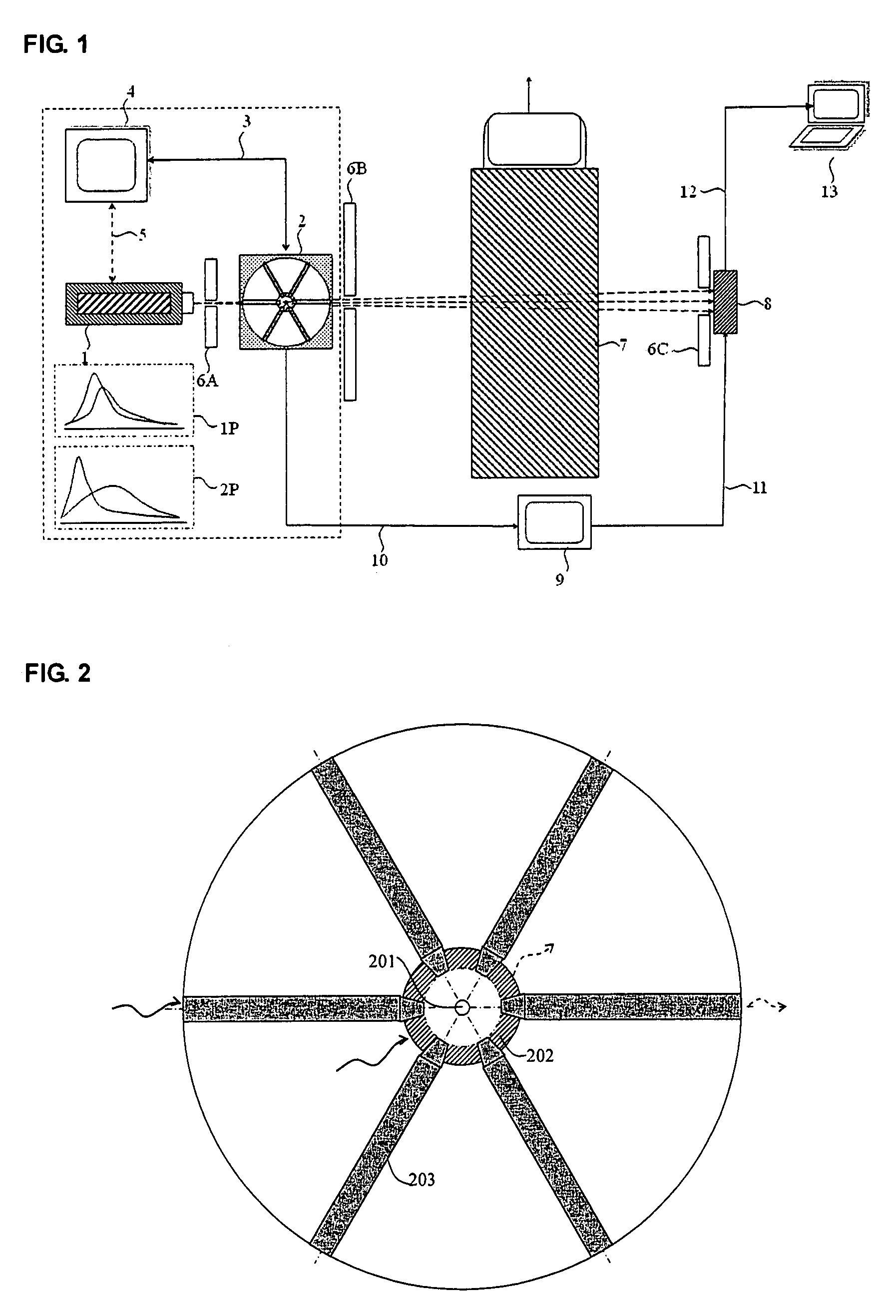

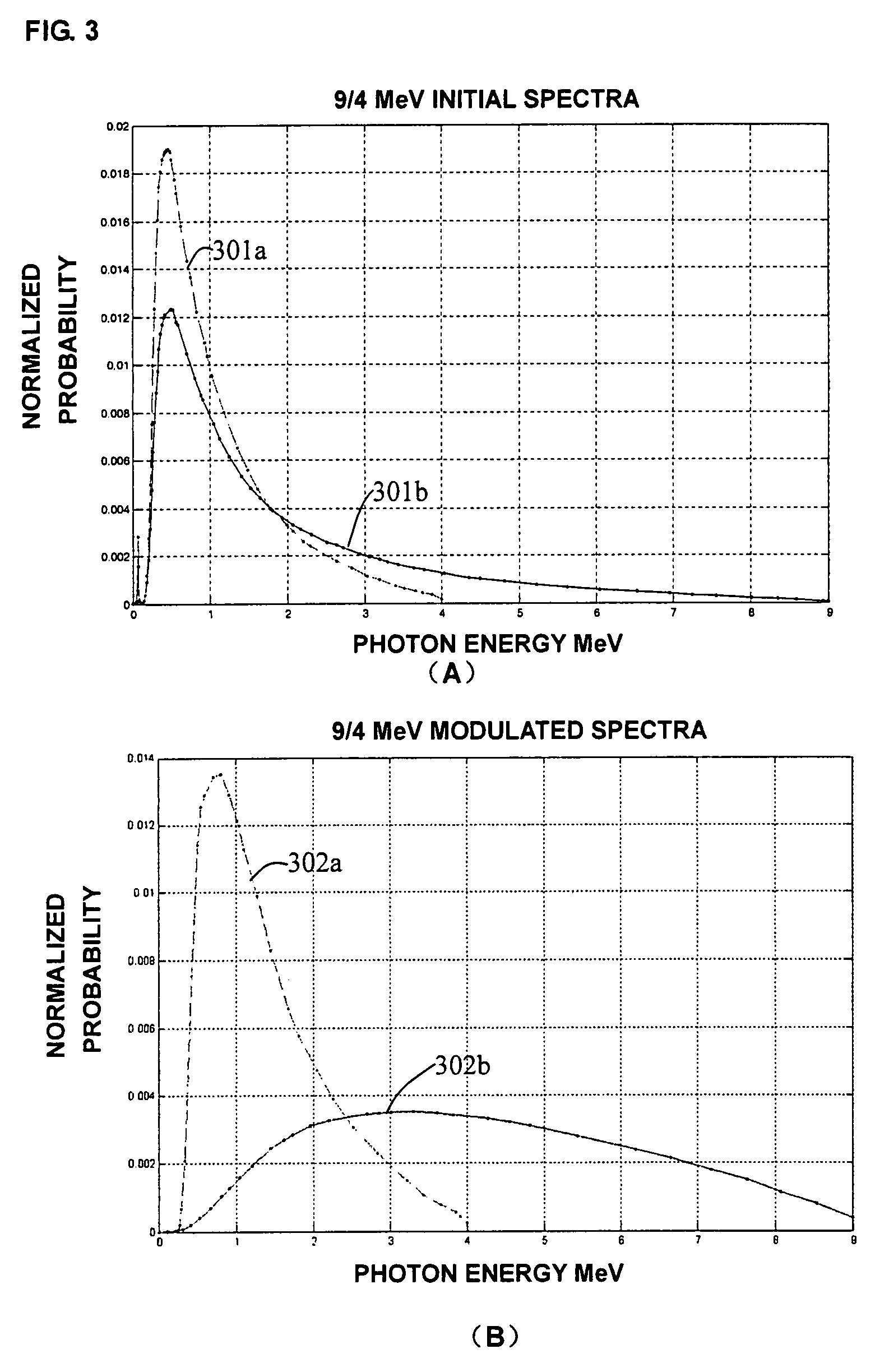

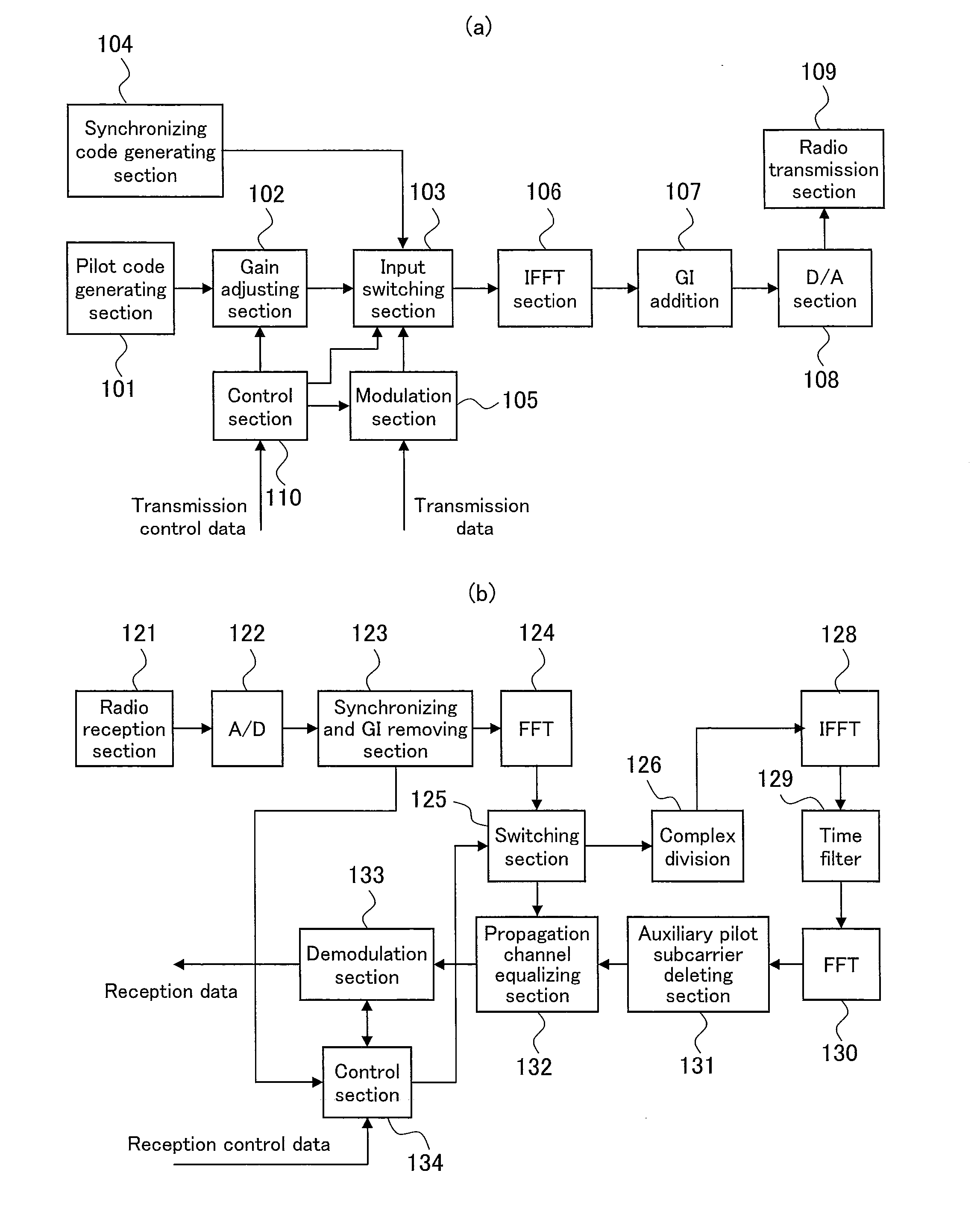

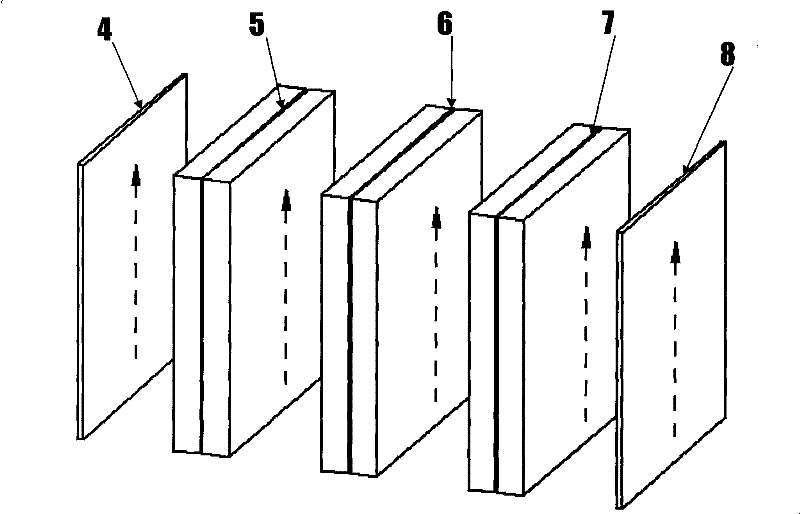

Energy spectrum modulation apparatus, material discrimination method and device, image processing method

InactiveUS20070286329A1Optimizing SpectrumEquivalent energy differenceImage data processing detailsUsing wave/particle radiation meansImaging processingAir cargo

Disclosed are an energy spectrum modulation apparatus, a material discrimination method and a device thereof, as well as an image processing method are disclosed, which can discriminate the material in large- and medium-sized objects such as cargo containers, air cargo containers, etc. by using X-rays having different energy levels. The energy spectrum modulation apparatus comprises a first energy spectrum modulation part for modulating a first ray having a first energy spectrum, and a second energy spectrum modulation part coupled to the first energy spectrum modulation part and for modulating a second ray having a second energy spectrum different from the first energy spectrum. The present invention can be used in the non-opening inspection for large-sized container cargo at places such as Customs, ports and airports.

Owner:NUCTECH CO LTD +1

Fluorenyl windmill grid material and preparation and application method thereof

ActiveCN105646529ATest thermal stabilityMild conditionsOrganic chemistrySolid-state devicesSolubilityPolymer science

The invention relates to a fluorenyl windmill grid material and a preparation and application method thereof, and belongs to the field of organic molecular materials and high and new photoelectric technologies. The fluorenyl windmill grid material is cyclic oligomer with fluorenyl micromolecules as monomers, and the specific general structural formula is shown in the description. The material has the advantages that the fluorenyl windmill grid material has both porous characteristics and semiconductor photoelectric characteristics; raw materials are cheap and easy to obtain, reaction conditions are mild, and operation is easy; the fluorenyl windmill grid material has good mechanical properties of a nanomaterial; the fluorenyl windmill grid material has good solubility, and nanofilm processing or fibration processing is facilitated; with a rigid framework, the fluorenyl windmill grid material is high in glass transition temperature, high in thermal stability, electrochemical stability and spectrum stability and the like. Thus, the fluorenyl windmill grid material is expected to become a new-generation practical organic micromolecular photoelectric material and has good application prospects in the fields of organic electronics, spintronics, optoelectronics, mechatronics, nanobiology and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

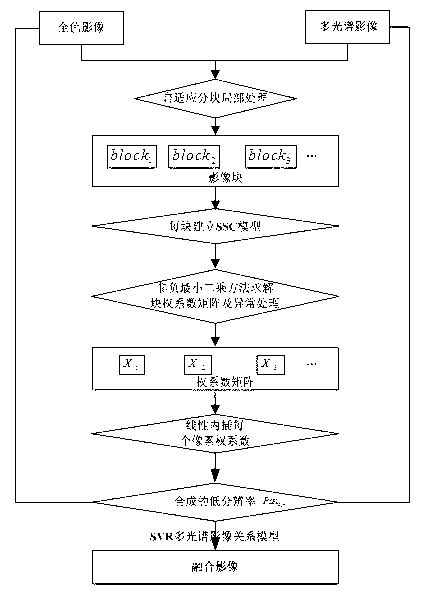

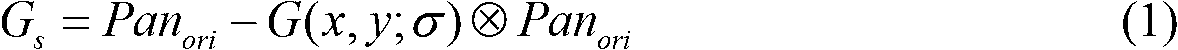

Remote-sensing image fusion method based on local correlation of light spectrum and space

InactiveCN102982517AQuality improvementThe relationship is accurateImage enhancementSelf adaptiveNon-negative least squares

The invention provides a remote-sensing image fusion method based on local correlation of light spectrum and space. According to the remote-sensing image fusion method based on the local correlation of the light spectrum and the space, a strategy of self-adaption partitioning local optimization is adopted, a whole image is partitioned, and then an observation model and a relevant fusion model are established in each image block; a weight coefficient matrix is solved by means of the non negative least square method in a light spectrum and space coherent image fusion model solving process, and the weight coefficient matrix is obtained after abnormal processing when a matrix is irreversible; a weight coefficient of each pixel is obtained after bilinear interpolation is carried out to a solved block weight coefficient matrix, and further an imitation low-resolution panchromatic image value of each pixel is obtained, and then fusion processing can be carried out pixel by pixel after the image value is put in the observation model. According to the remote-sensing image fusion method based on the local correlation of the light spectrum and the space, the original multispectral image space resolution ratio is improved, and simultaneously original spectral information can be effectively kept, and strong self-adaption processing capacity to an existing optical sensor is achieved.

Owner:WUHAN UNIV

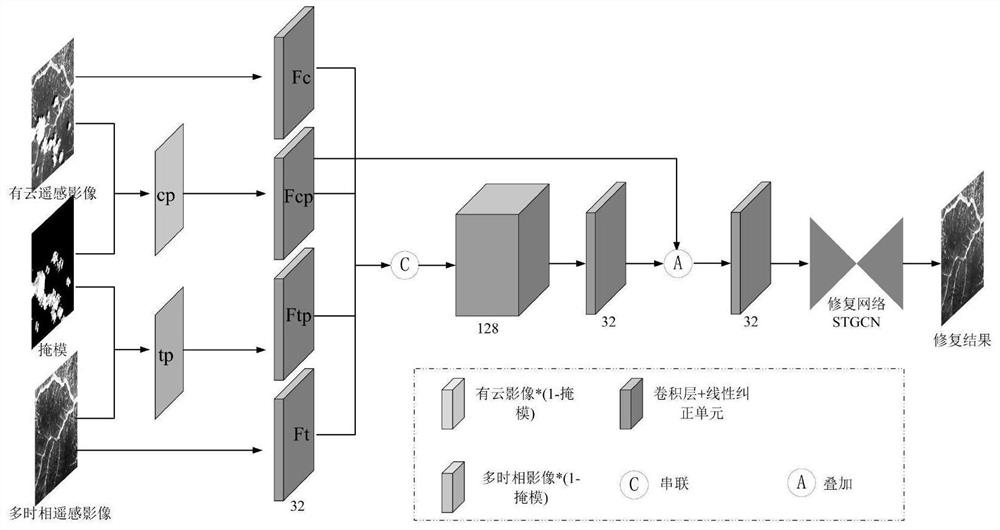

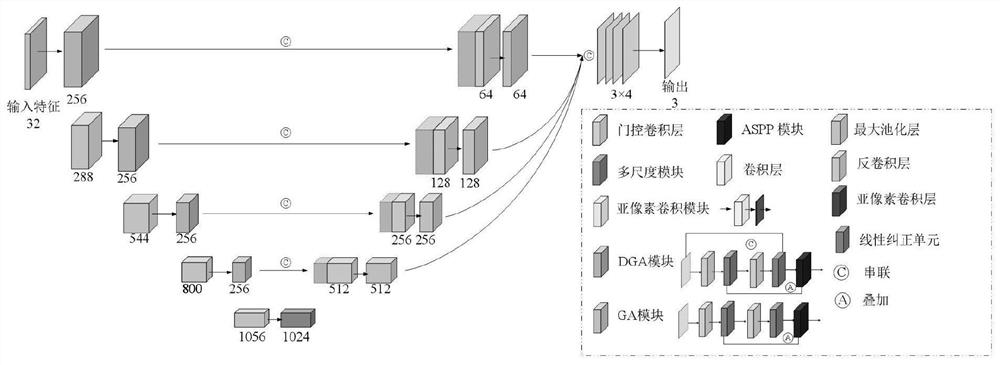

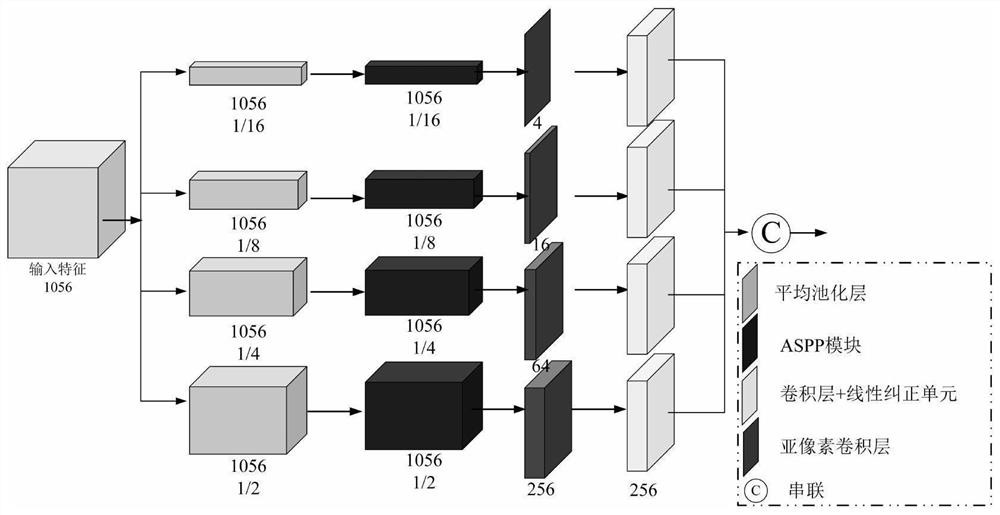

Remote sensing image cloud and shadow restoration method based on gated convolution

ActiveCN112288647AReduce the amount of parametersHigh precisionImage enhancementImage analysisComputer visionComputer science

The invention relates to a cloud and shadow restoration method based on gated convolution in combination with multi-temporal data. The method comprises the following steps: constructing a sample library by utilizing existing remote sensing images; secondly, designing a multi-temporal cloud and shadow restoration network based on gated convolution for training, and deeply mining the correlation andfeatures between a cloudy remote sensing image multi-temporal cloudless image and a pure pixel region containing missing information; then, for a real cloud-containing image, using an existing clouddetection method firstly for carrying out pixel-level semantic segmentation, and selecting a result with a high recall rate; and finally, using the trained cloud and shadow restoration network, a highrecall rate detection result, a real cloud-containing image and corresponding multi-temporal data to perform restoration work, and rebuilding missing information with high fidelity on the basis of ensuring spectral information. The invention has the advantages that the robustness is high, and the method can adapt to detection and restoration of remote sensing image clouds and shadows of differentscales.

Owner:WUHAN UNIV

Energy spectrum modulation apparatus, material discrimination method and device, image processing method

InactiveUS7702075B2Optimizing SpectrumEquivalent energy differenceImage data processing detailsUsing wave/particle radiation meansImaging processingX-ray

Disclosed are an energy spectrum modulation apparatus, a material discrimination method and a device thereof, as well as an image processing method are disclosed, which can discriminate the material in large- and medium-sized objects such as cargo containers, air cargo containers, etc. by using X-rays having different energy levels. The energy spectrum modulation apparatus comprises a first energy spectrum modulation part for modulating a first ray having a first energy spectrum, and a second energy spectrum modulation part coupled to the first energy spectrum modulation part and for modulating a second ray having a second energy spectrum different from the first energy spectrum. The present invention can be used in the non-opening inspection for large-sized container cargo at places such as Customs, ports and airports.

Owner:NUCTECH CO LTD +1

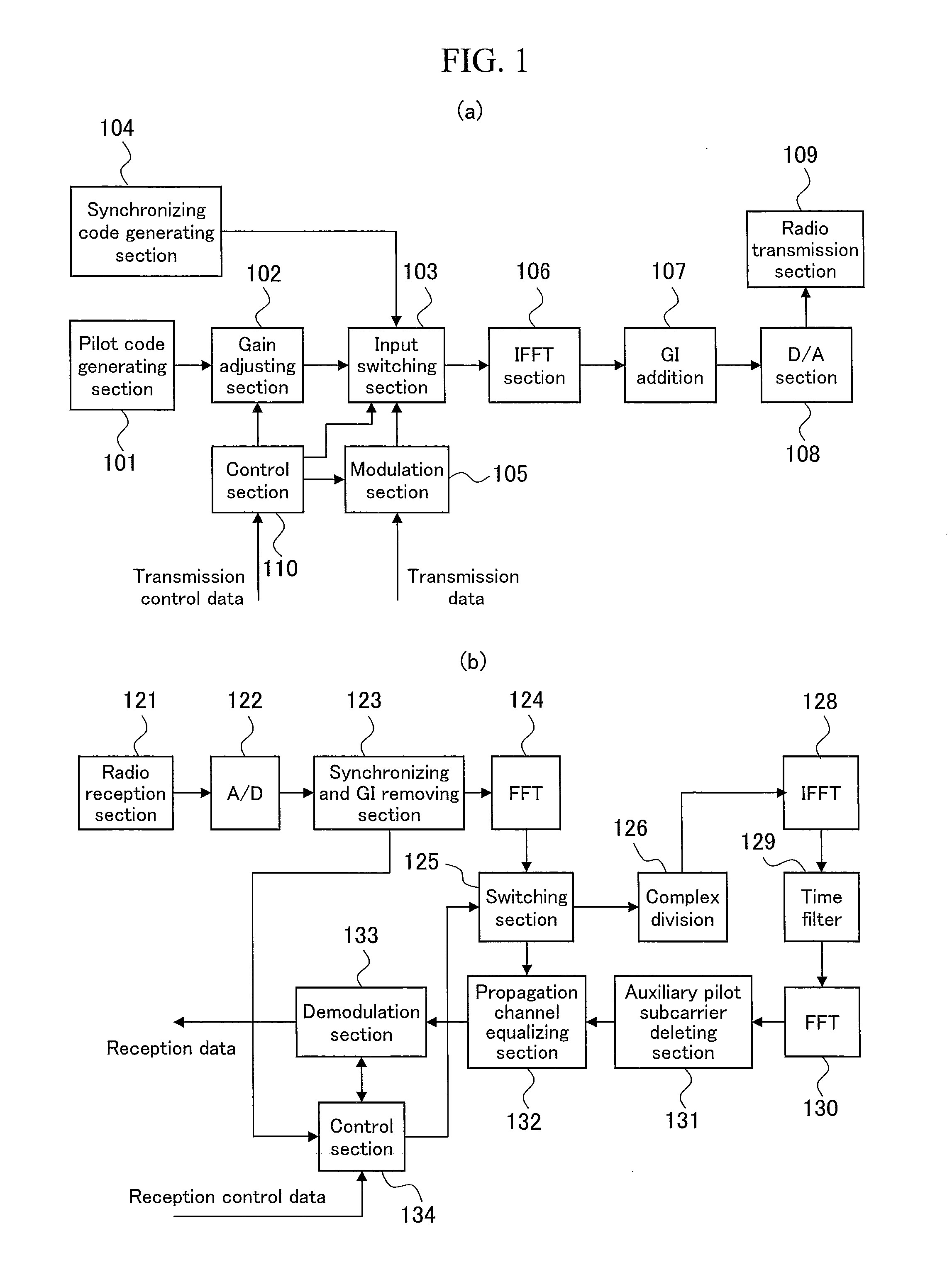

Communication apparatus

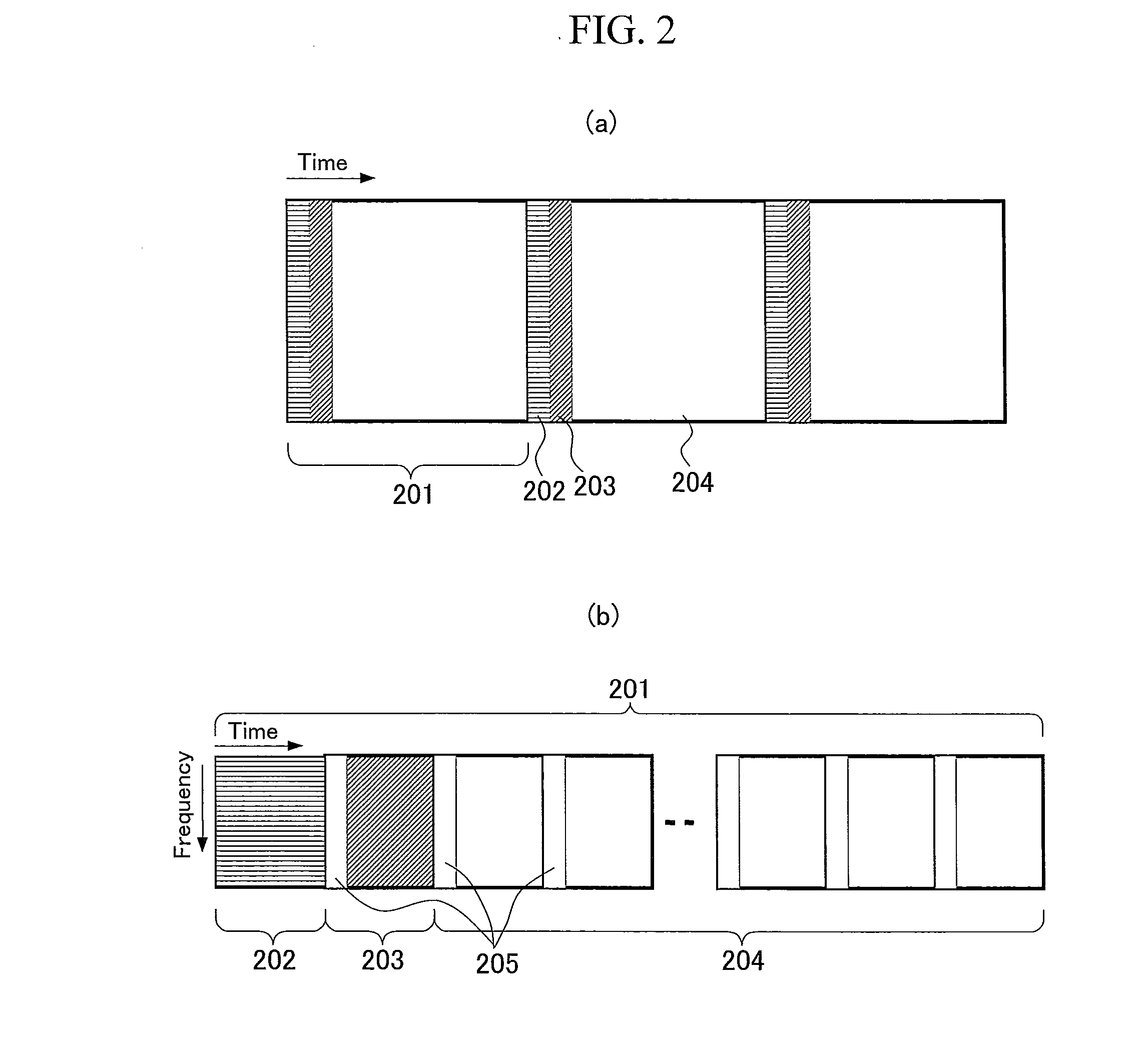

InactiveUS20100220797A1Reduce transmissionReduce signal distortionTransmission path divisionAmplitude-modulated carrier systemsTime domainFrequency spectrum

When in-phase data with an amplitude of 1 is located in each subcarrier, the envelope waveform of a time domain signal contains guard band 304 in an IDFT processing band. Thus, the waveform is such that a side lobe 306 is widely extended around the position of a point in time 0, as shown in FIG. 3(c). To allow the side lobe 306 to be suppressed, the amplitude of each band end of a transmission spectrum is smoothly reduced. Then, in a communication apparatus, the extension of the waveform on a time domain can be reduced by optimizing the spectrum of auxiliary pilot subcarriers.

Owner:SHARP KK

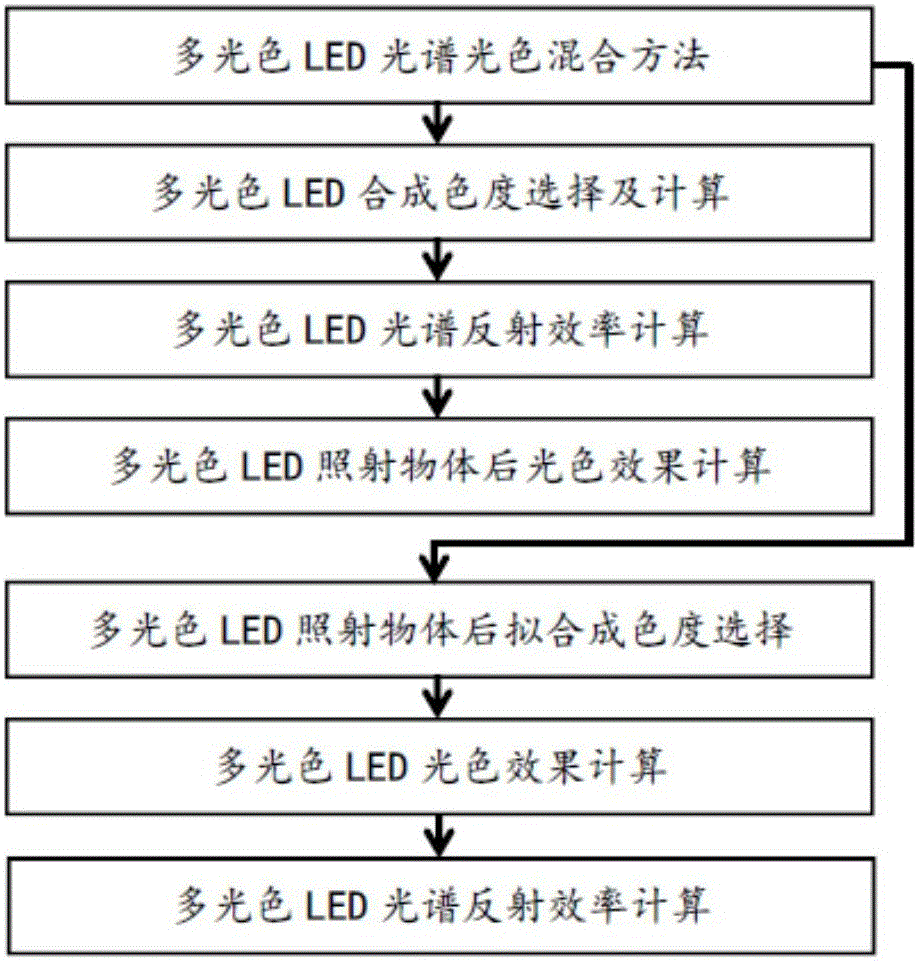

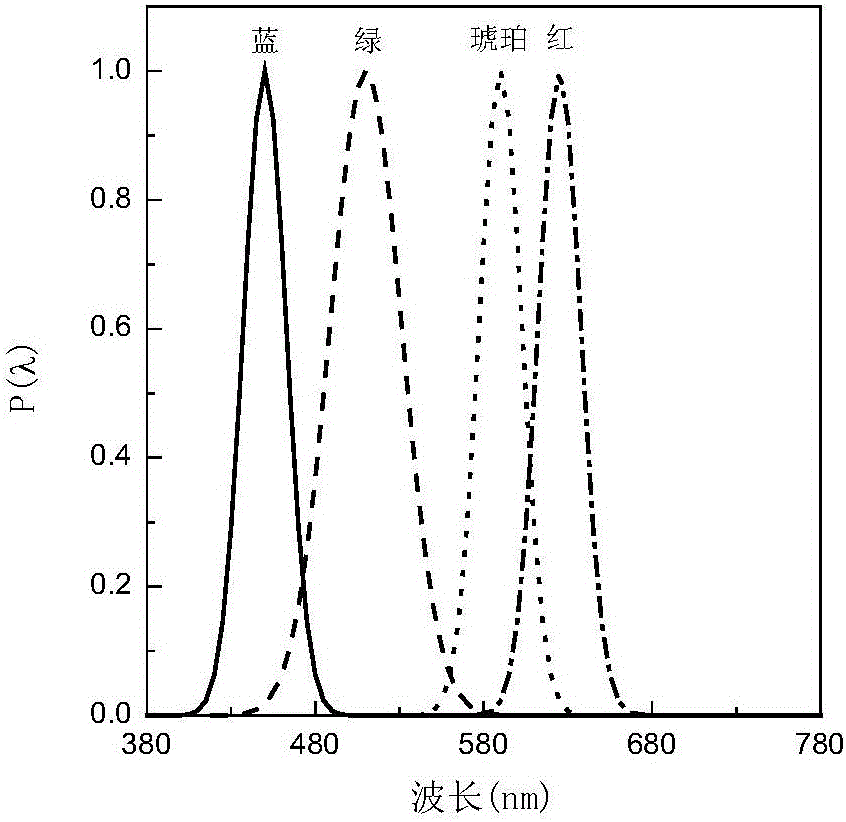

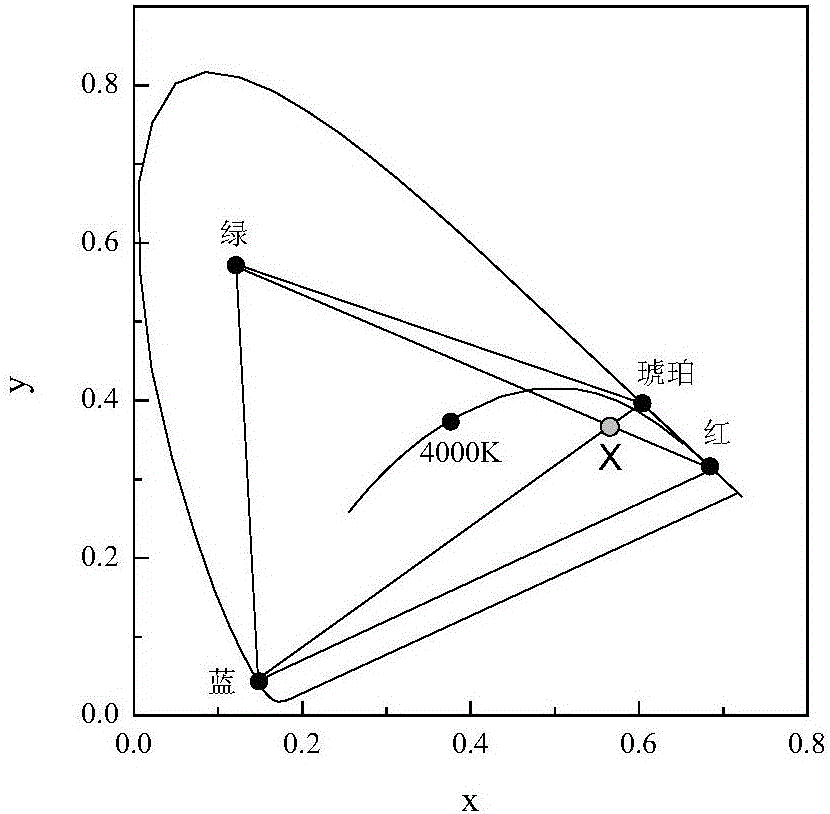

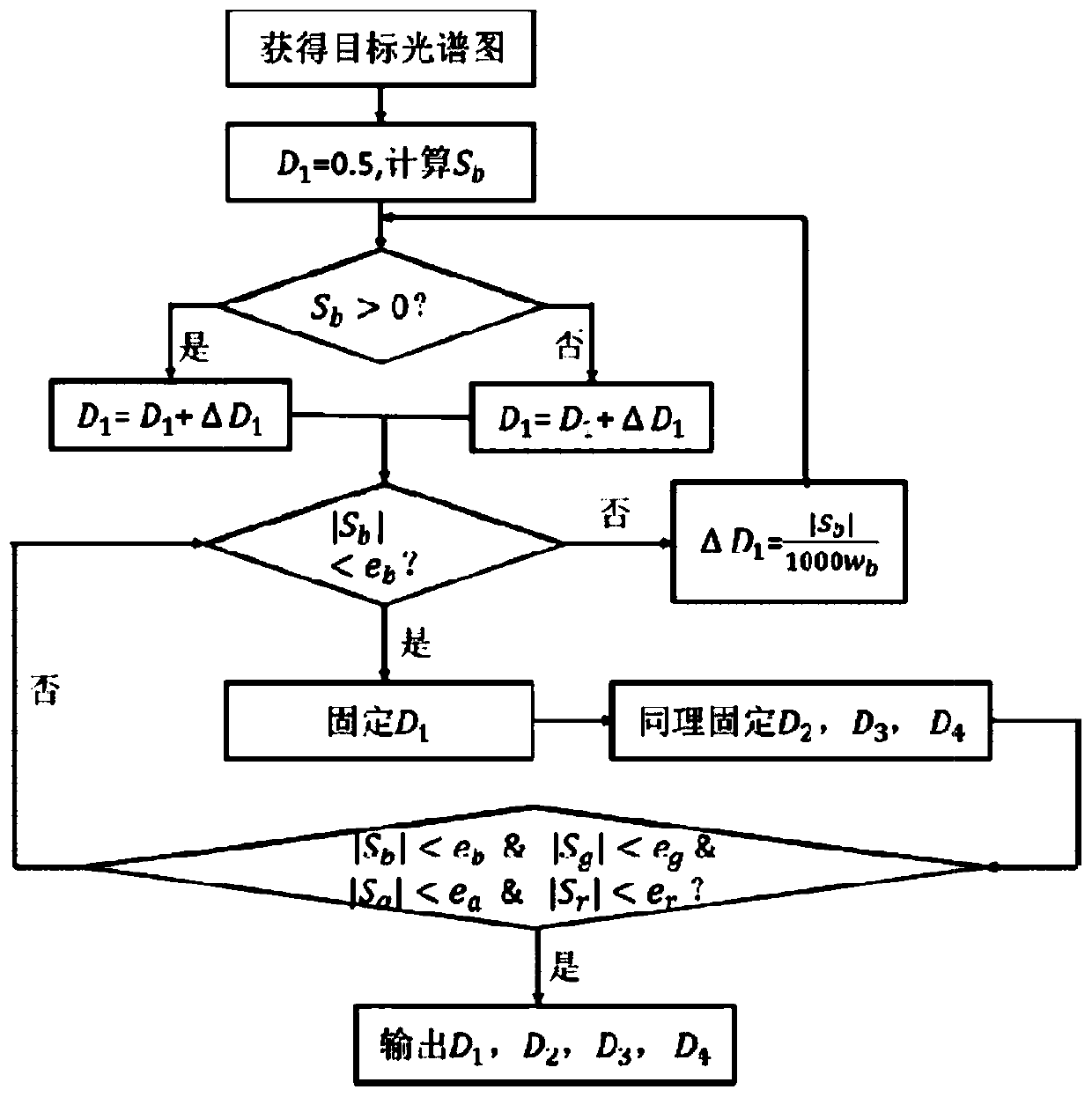

Method for optimizing spectrum of multi-light-color LED

ActiveCN105138827AAuxiliary Lighting DesignComfortable reading effectSpecial data processing applicationsColor effectHybrid approach

The invention discloses a method for optimizing a spectrum of a multi-light-color LED. The method comprises the following steps 1, 2, 3 and 4 or 1, 5, 6 and 7 of: step 1, carrying out a method for mixing light colors of the spectrum of the multi-light-color LED; step 2, selecting and computing a synthetic chromaticity of the multi-light-color LED; step 3, computing spectral reflection efficiency of the multi-light-color LED; step 4, computing a light color effect of the multi-light-color LED after irradiating an object; step 5, selecting fitting chromaticity of the multi-light-color LED after irradiating the object; step 6, computing the light color effect of the of the multi-light-color LED; and step 7, computing the spectral reflection efficiency of the multi-light-color LED. According to the method, the spectral reflection efficiency and the light color effect are improved by virtue of a spectral optimization technology; and the method is applicable to landscape lighting, scene lighting, commercial lighting and certain functional lighting occasions and the like.

Owner:SHENZHEN UNIV +1

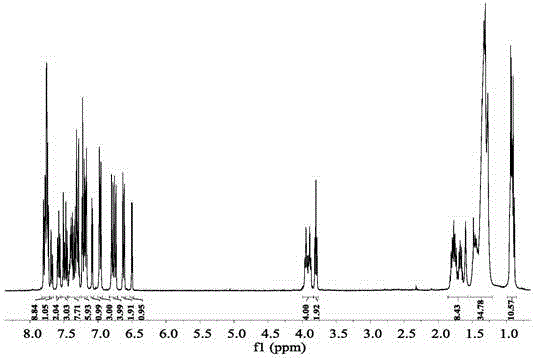

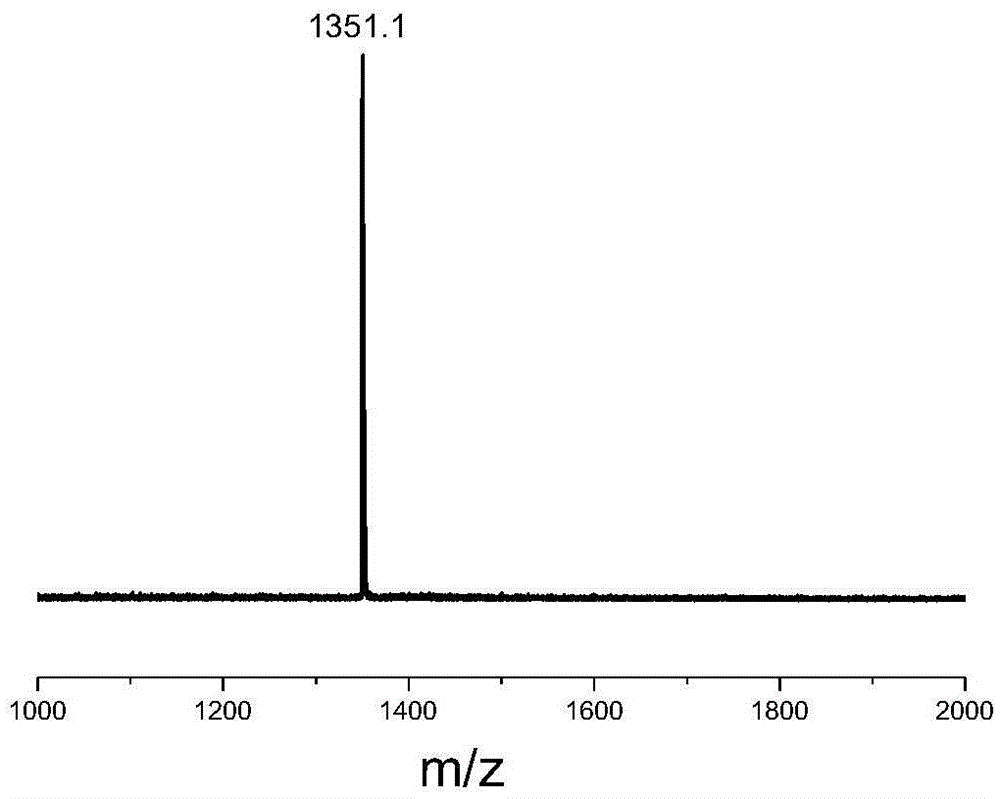

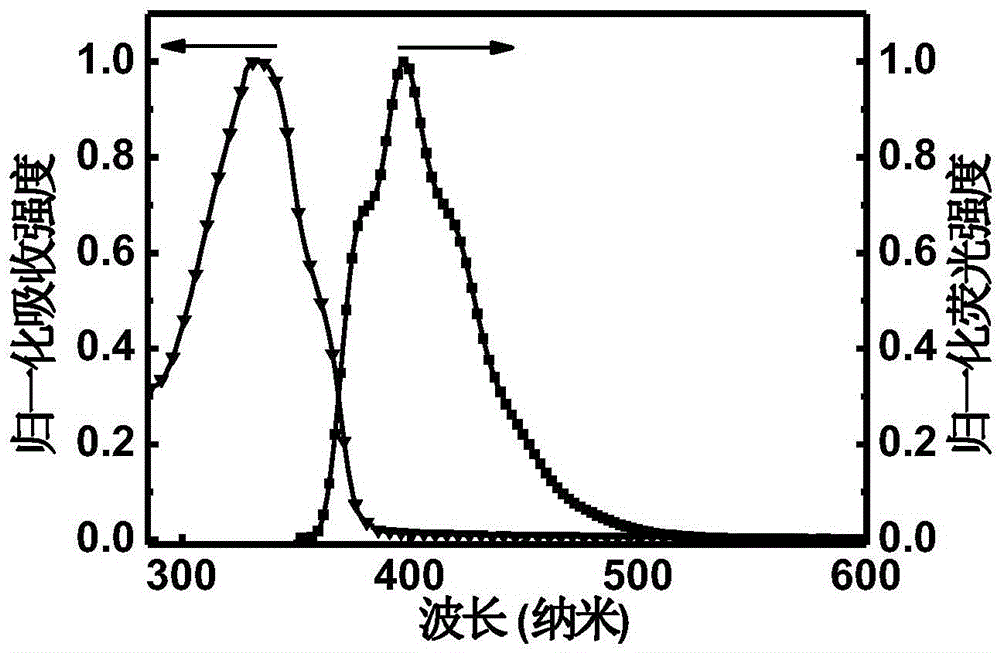

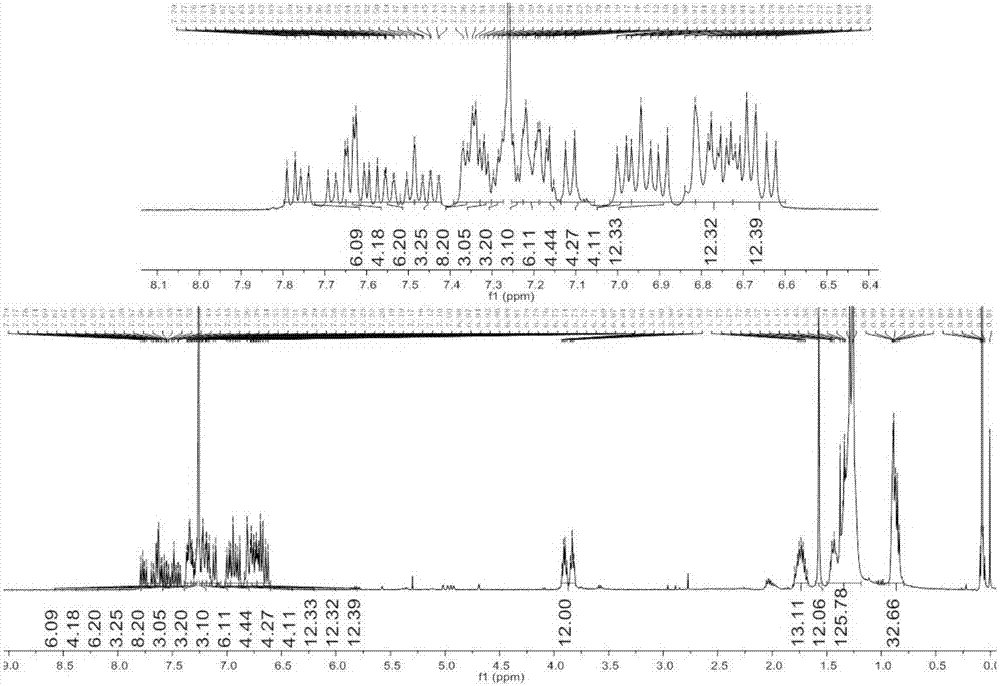

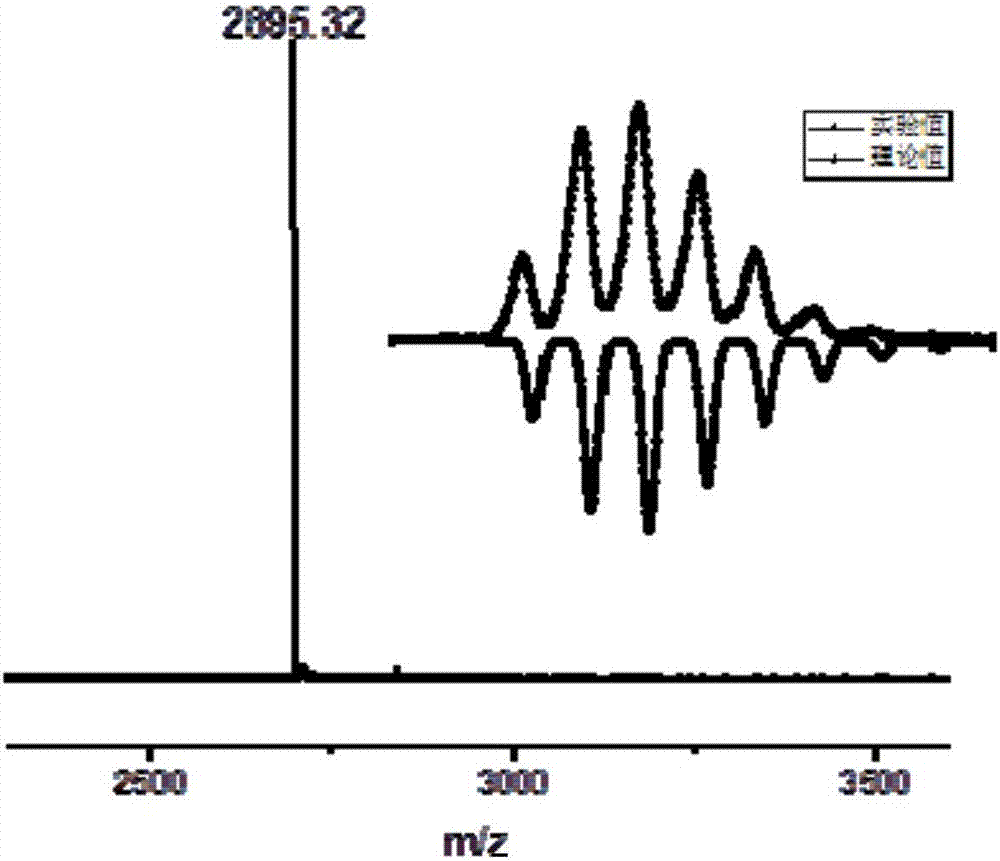

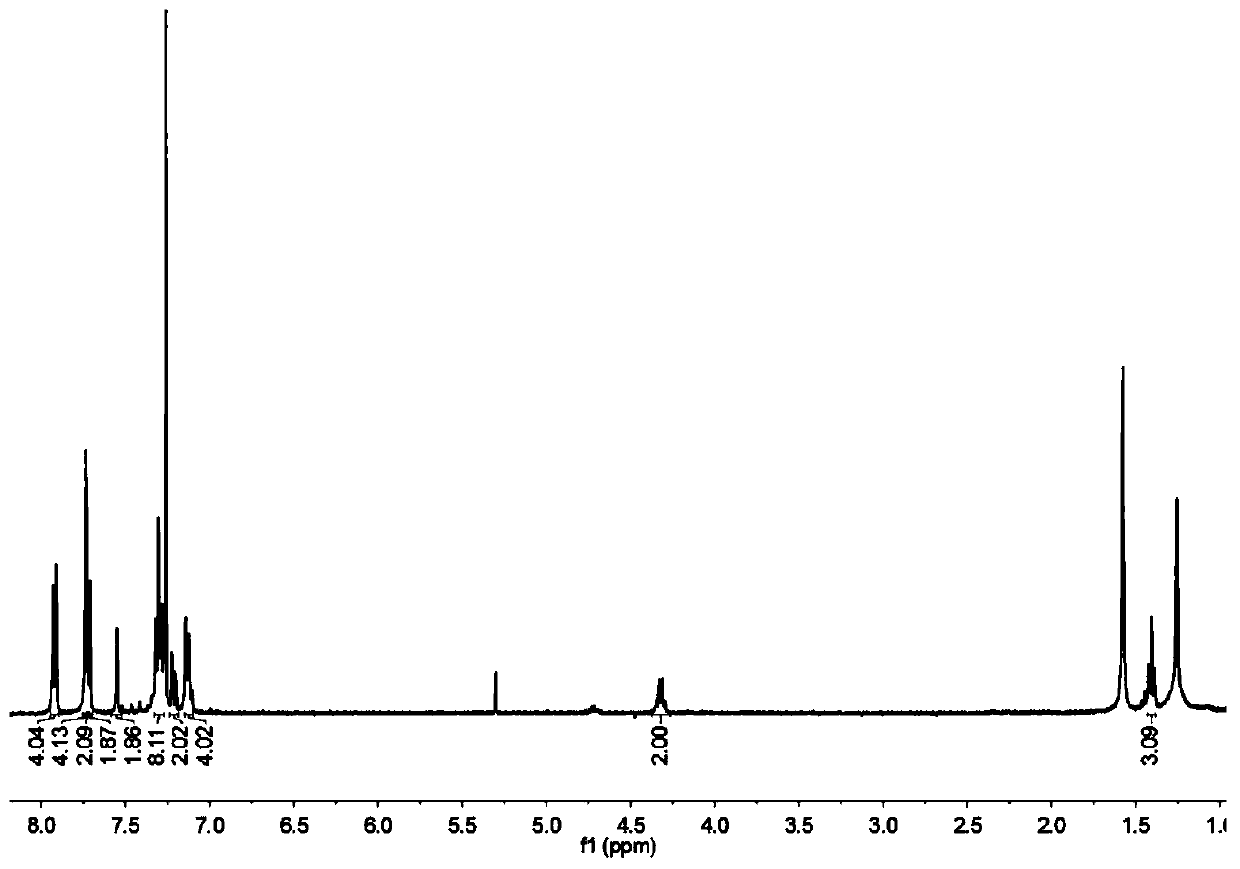

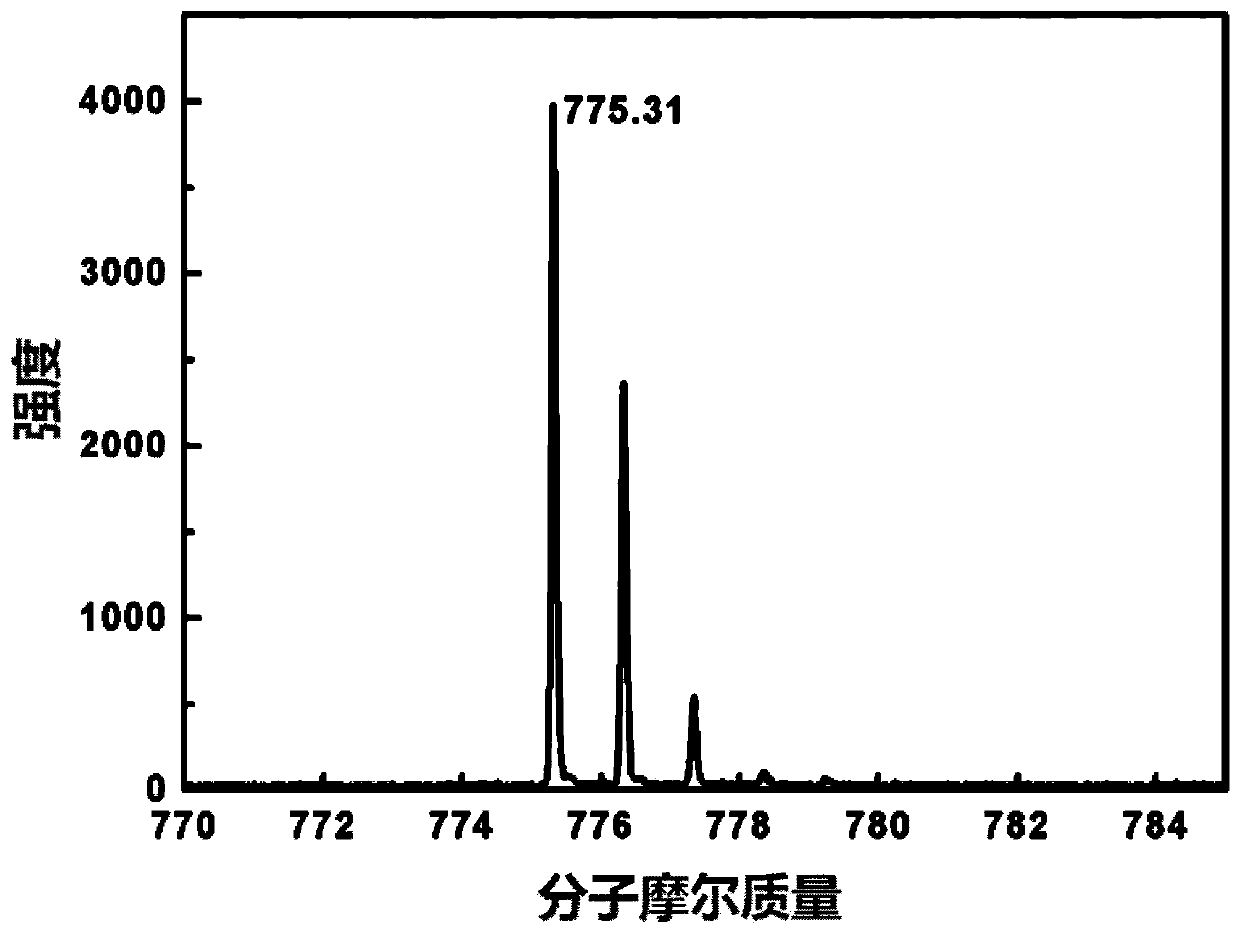

Fluorenyl triangular-prism-shaped organic cage compound, and preparation method and application of compound

ActiveCN107501276AEasy to operateLarge cavityOrganic chemistryFluorescence/phosphorescenceSolubilityAlcohol

The invention discloses a fluorenyl triangular-prism-shaped organic cage compound, and a preparation method and an application of the compound. The fluorenyl triangular-prism-shaped organic cage compound has a structure represented as a formula I shown in the description. The preparation method comprises performing cyclization on fluorenyl dimeric tertiary alcohol under a Friedel-Crafts reaction which is catalyzed by an acid to obtain the fluorenyl triangular-prism-shaped organic cage compound. The fluorenyl triangular-prism-shape organic molecular cage has a large cavity and specific surface area, has good solubility, good heat, electrochemistry and optics stability, and thus has wide application prospects in the fields of organic light emitting devices, molecular recognition, porous materials, supramolecular chemistry and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

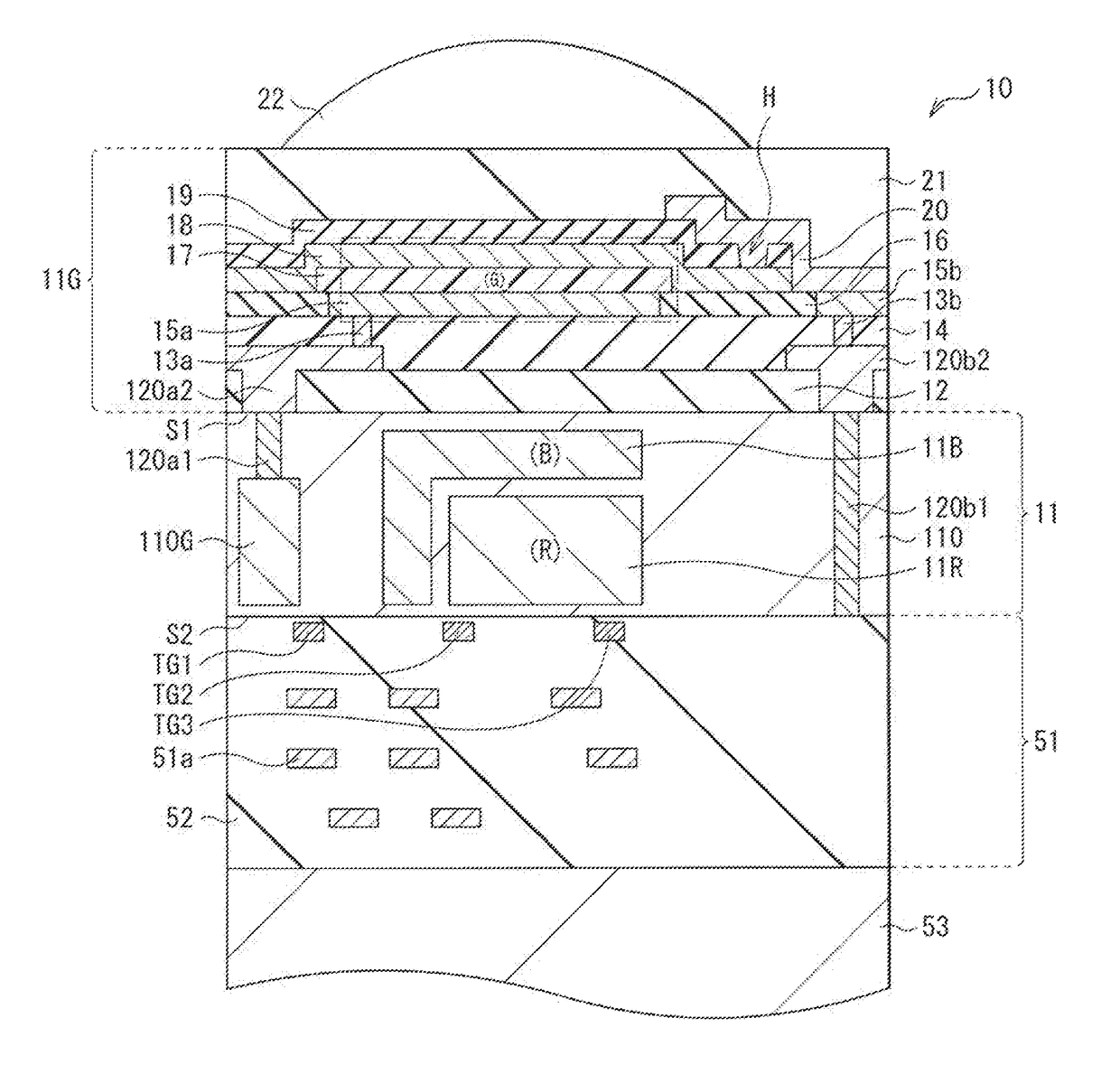

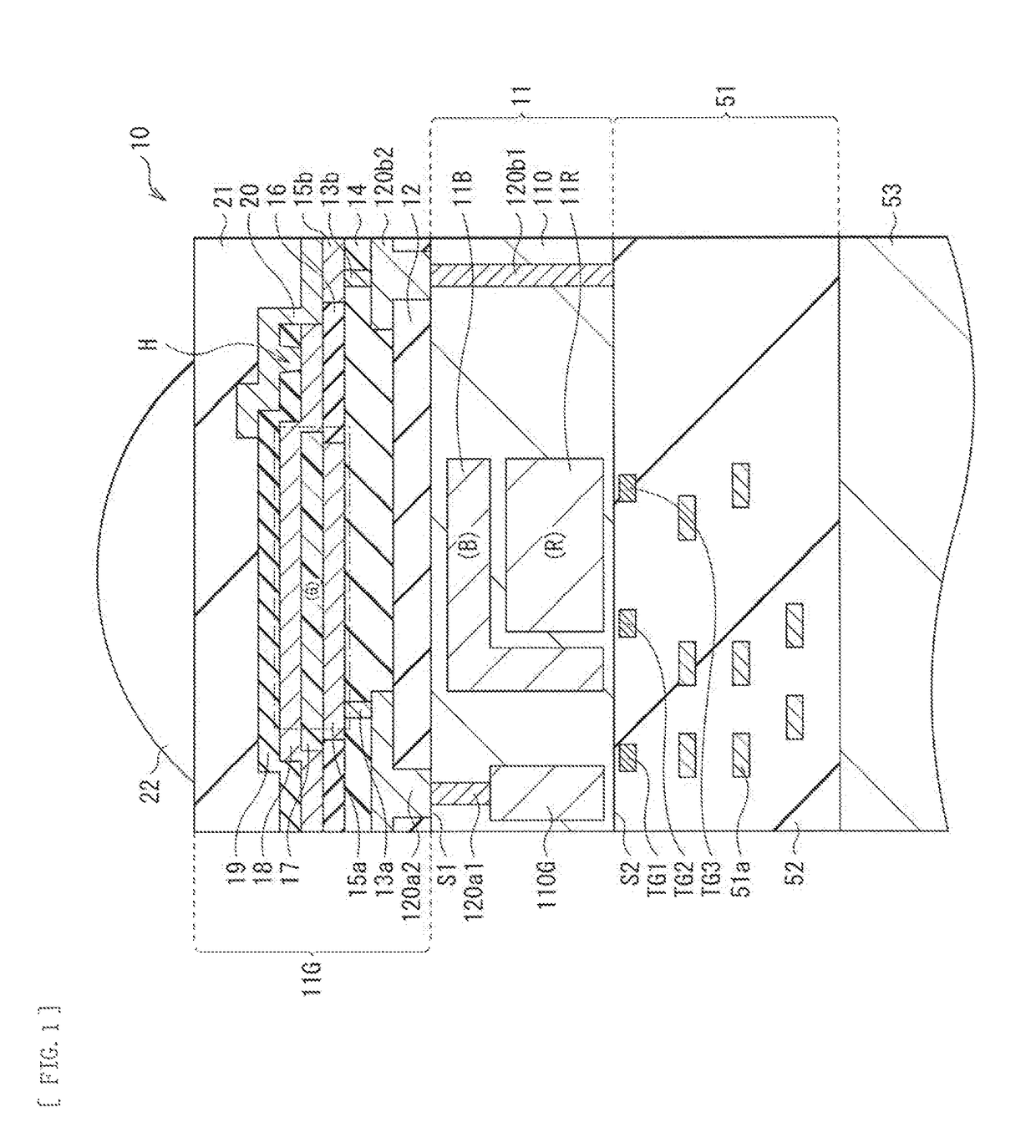

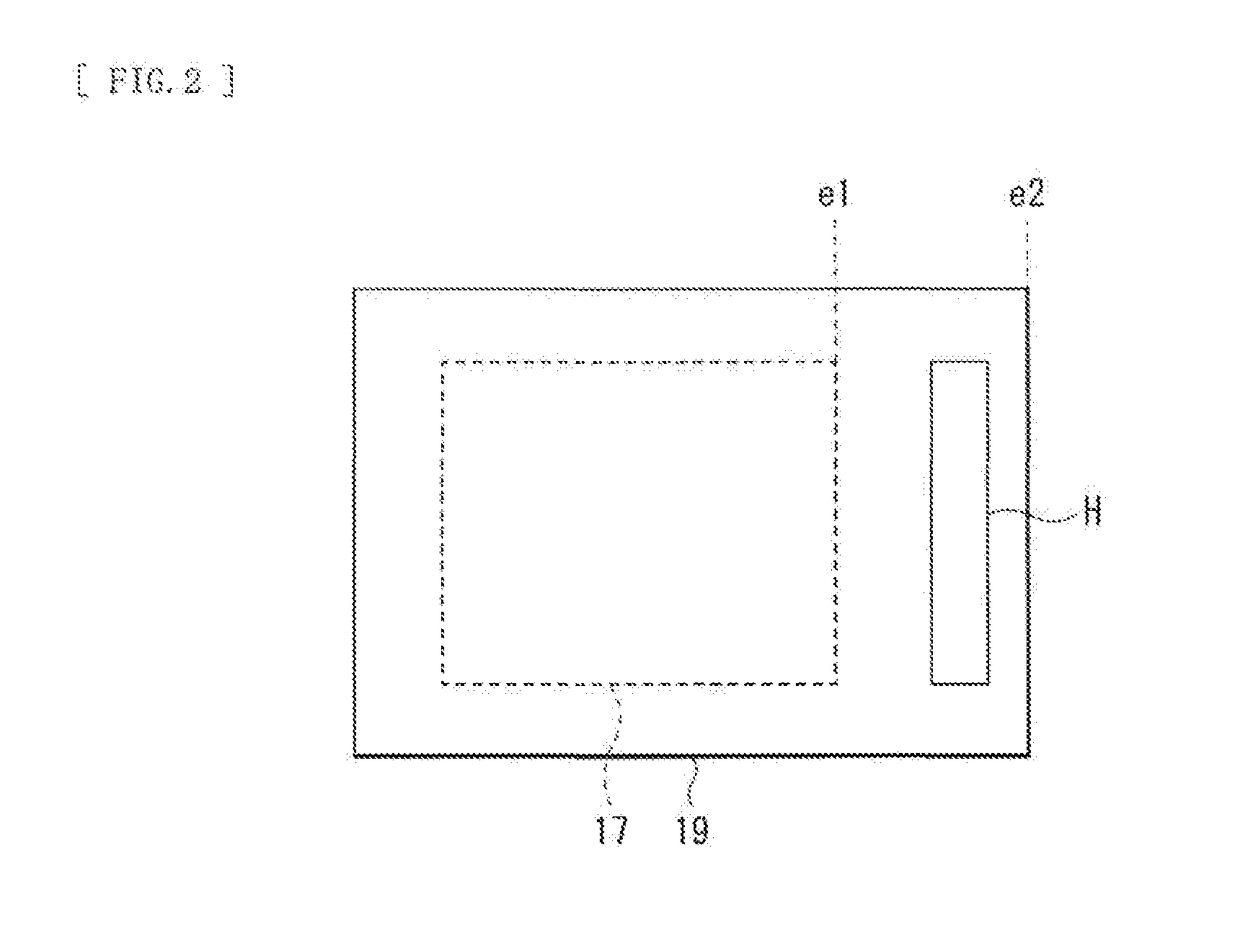

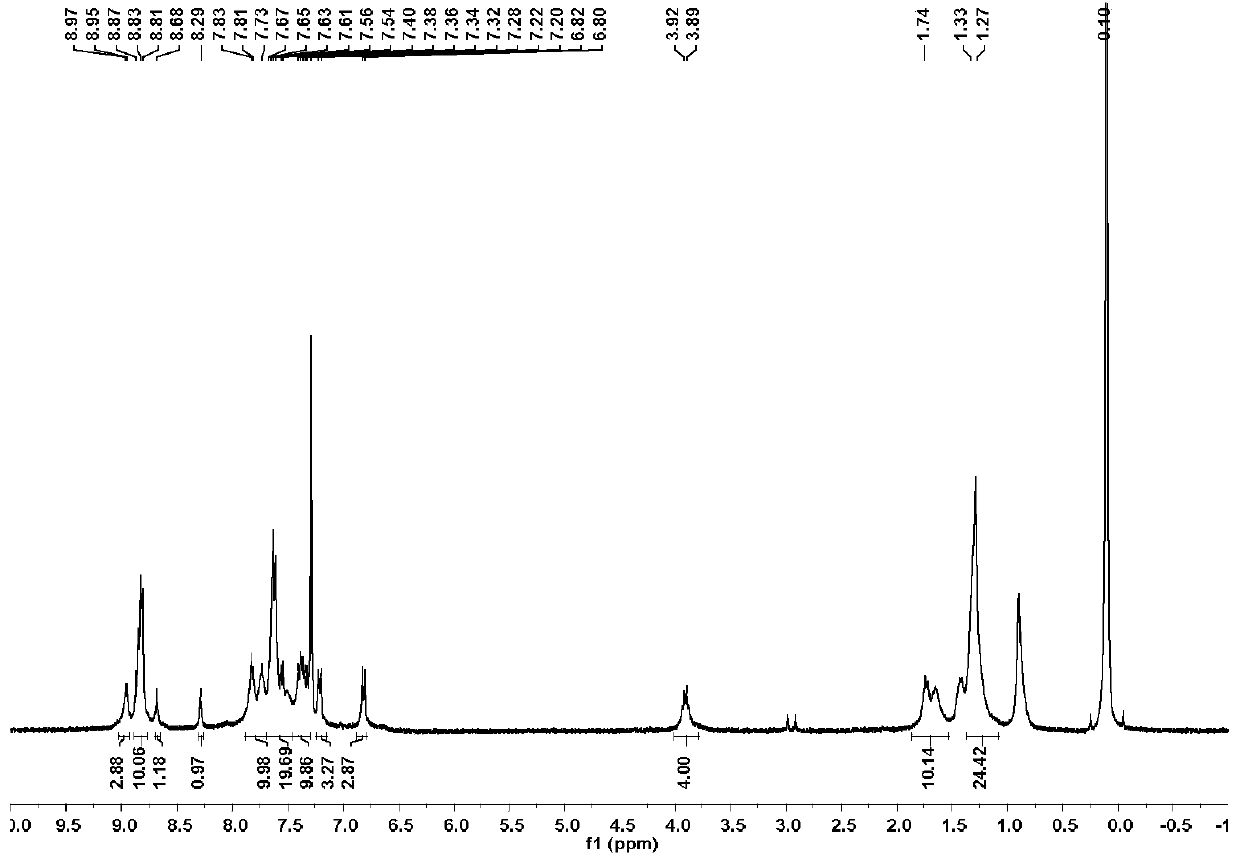

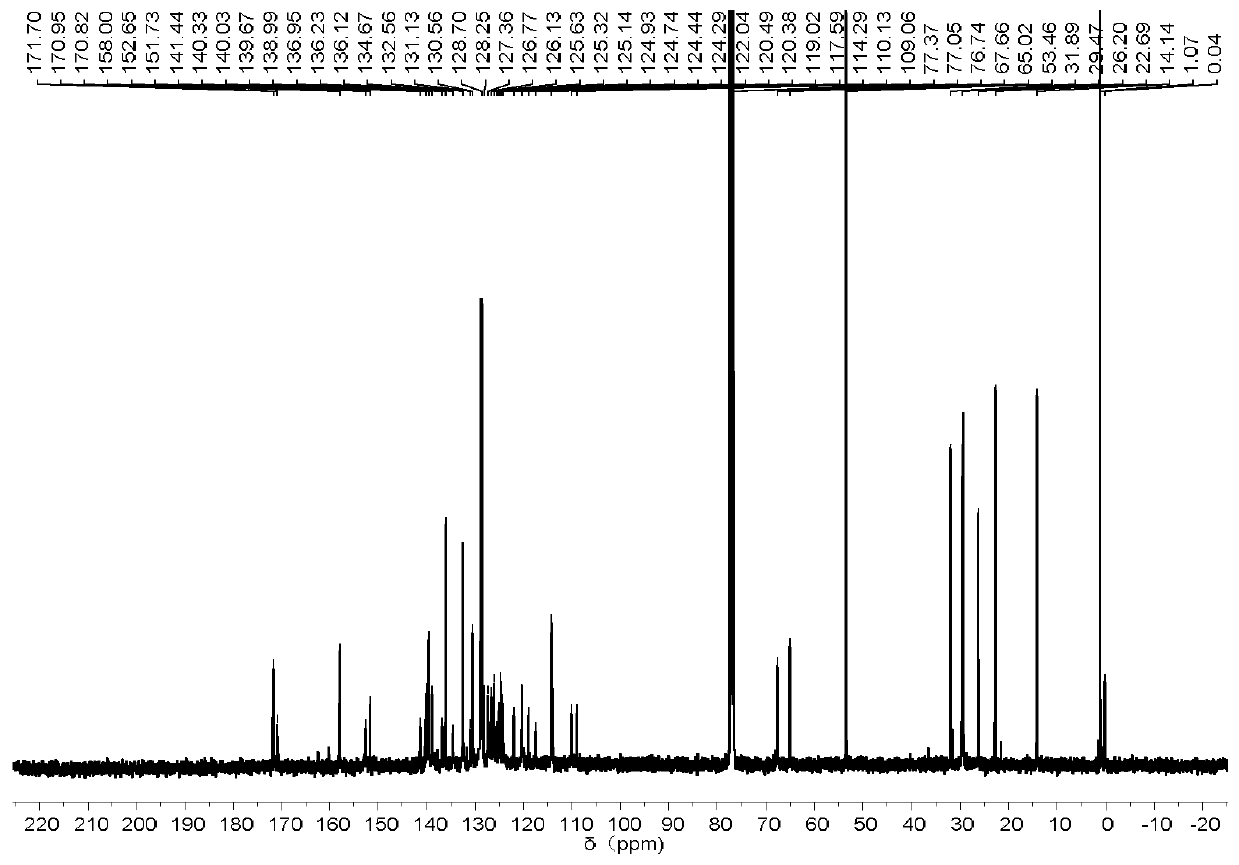

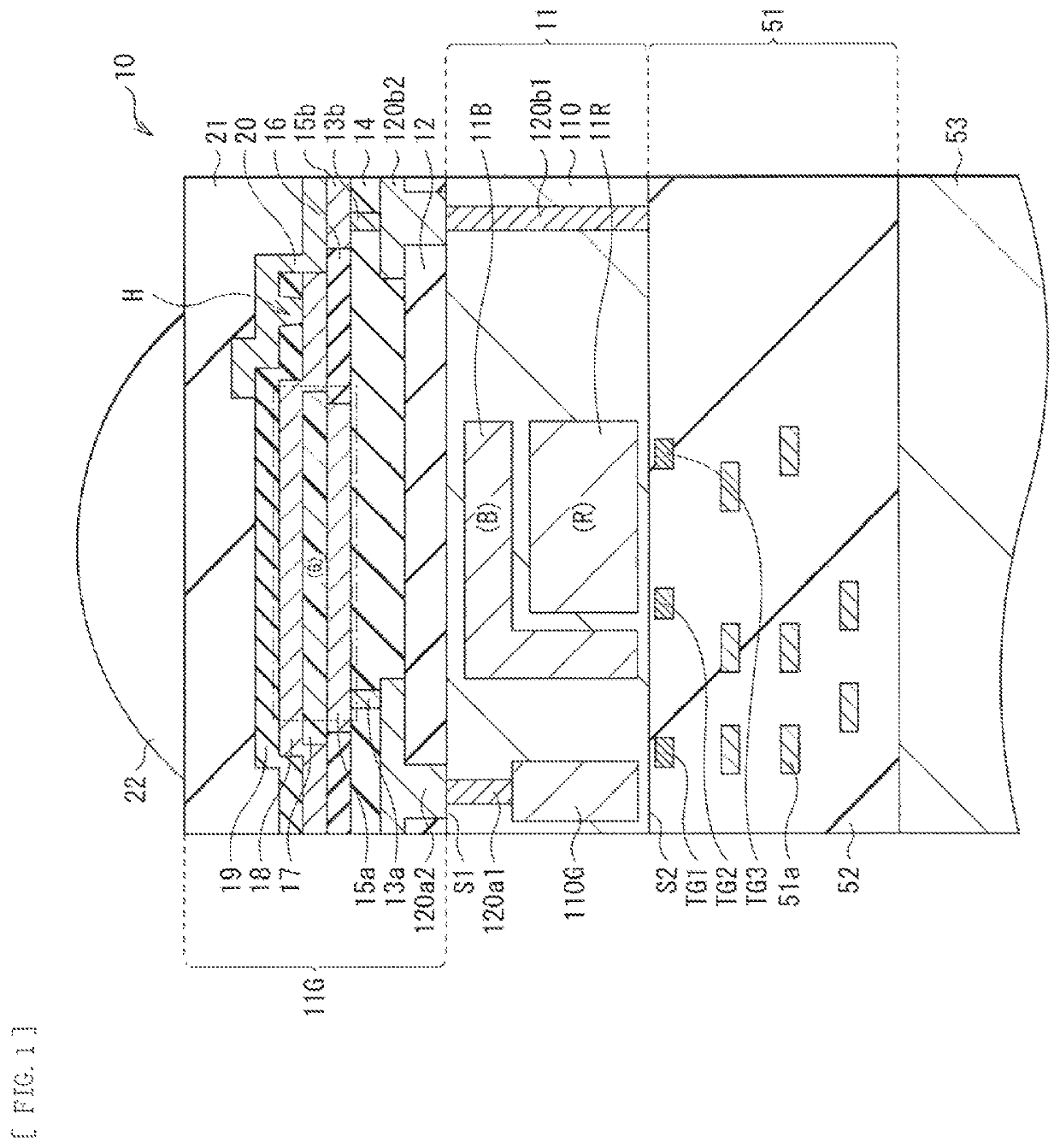

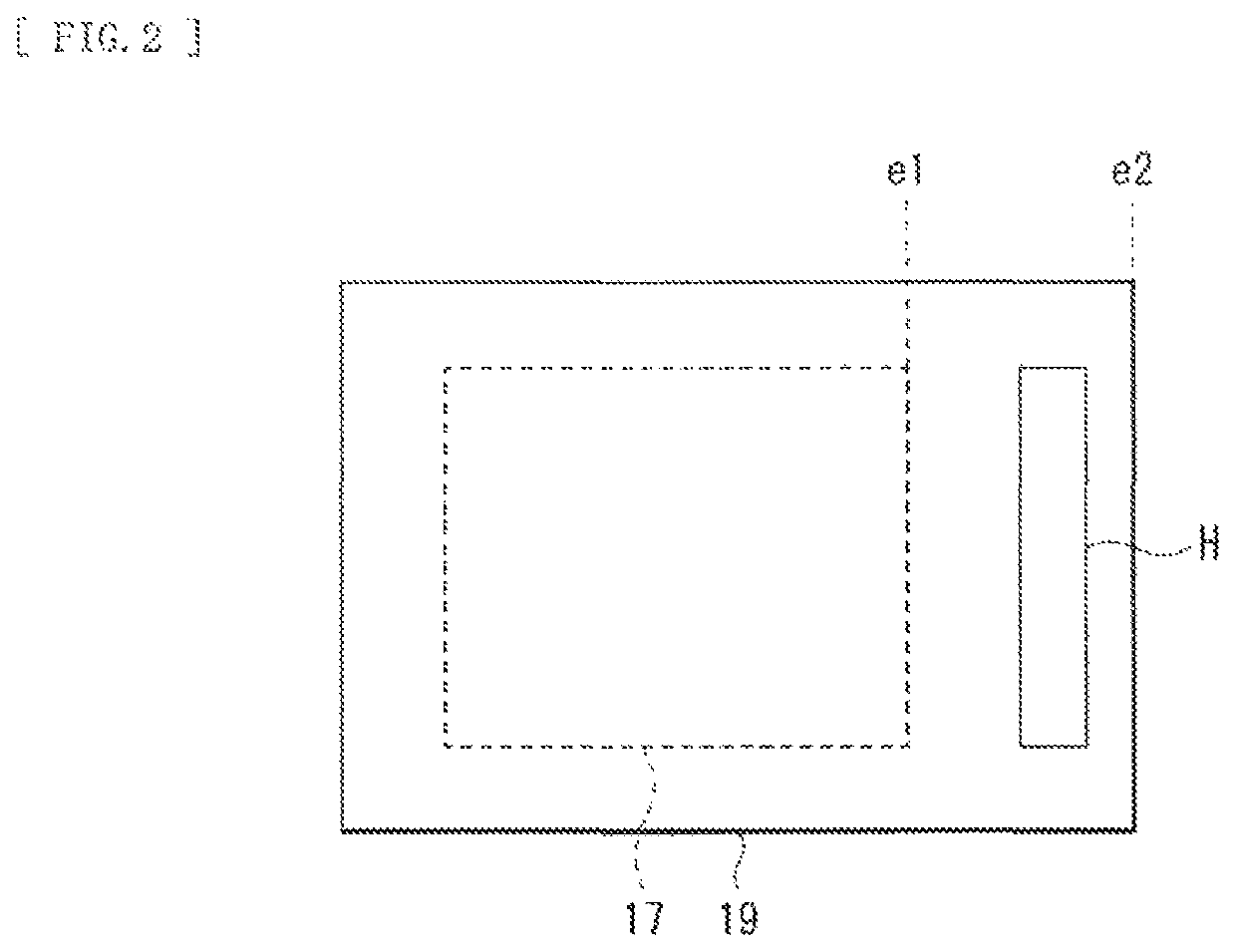

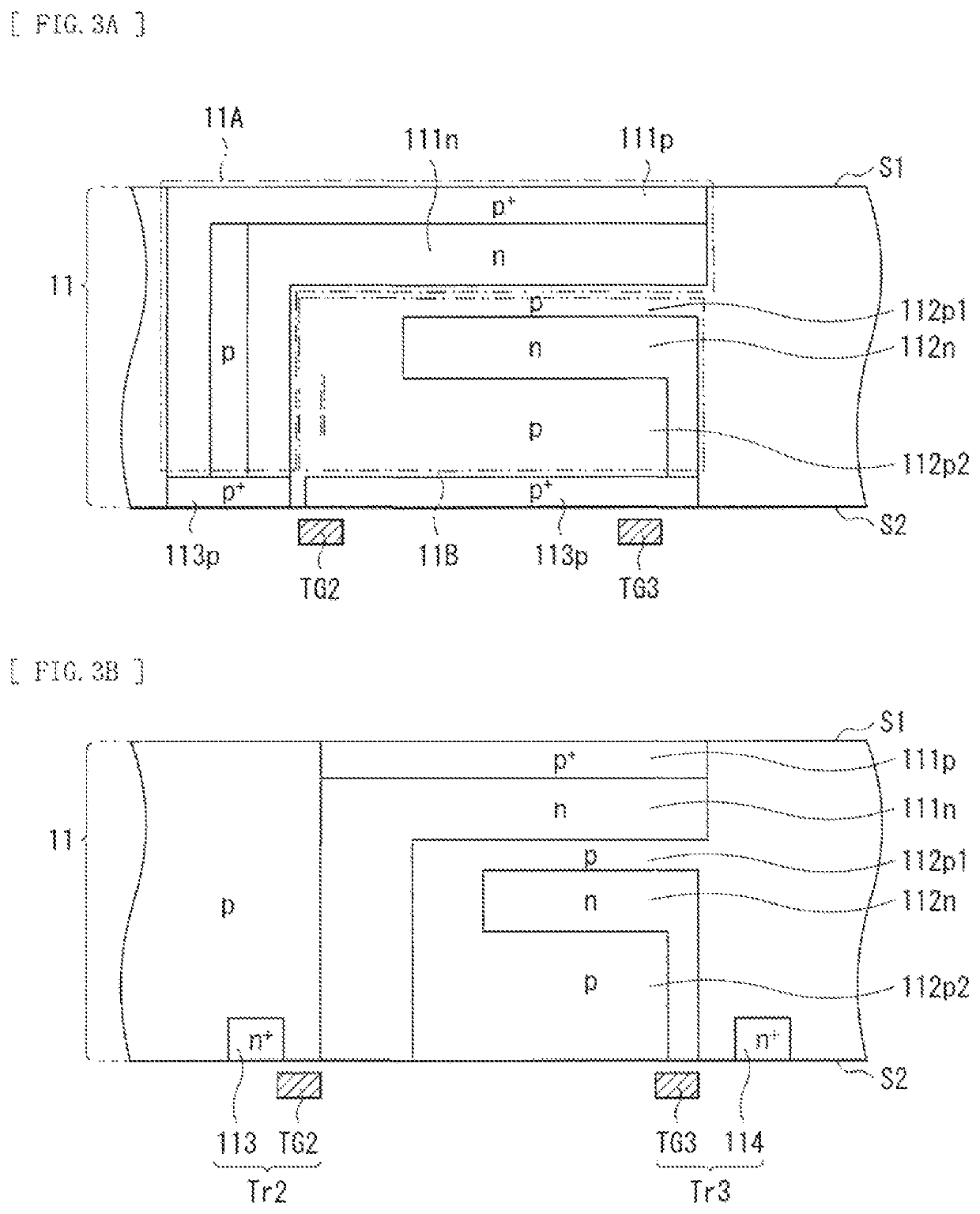

Photoelectric conversion element, solid-state imaging device, and electronic apparatus

ActiveUS20180159059A1Reduce interactionOptimizing SpectrumSolid-state devicesSemiconductor/solid-state device manufacturingPhotoelectric conversionOrganic semiconductor

A photoelectric conversion element according to an embodiment of the disclosure includes a first electrode and a second electrode, and an organic semiconductor layer. The first electrode and the second electrode are disposed to face each other. The organic semiconductor layer is provided between the first electrode and the second electrode, and contains a fullerene derivative modified by a substituent having an absorbance smaller than that of a fullerene.

Owner:SONY SEMICON SOLUTIONS CORP

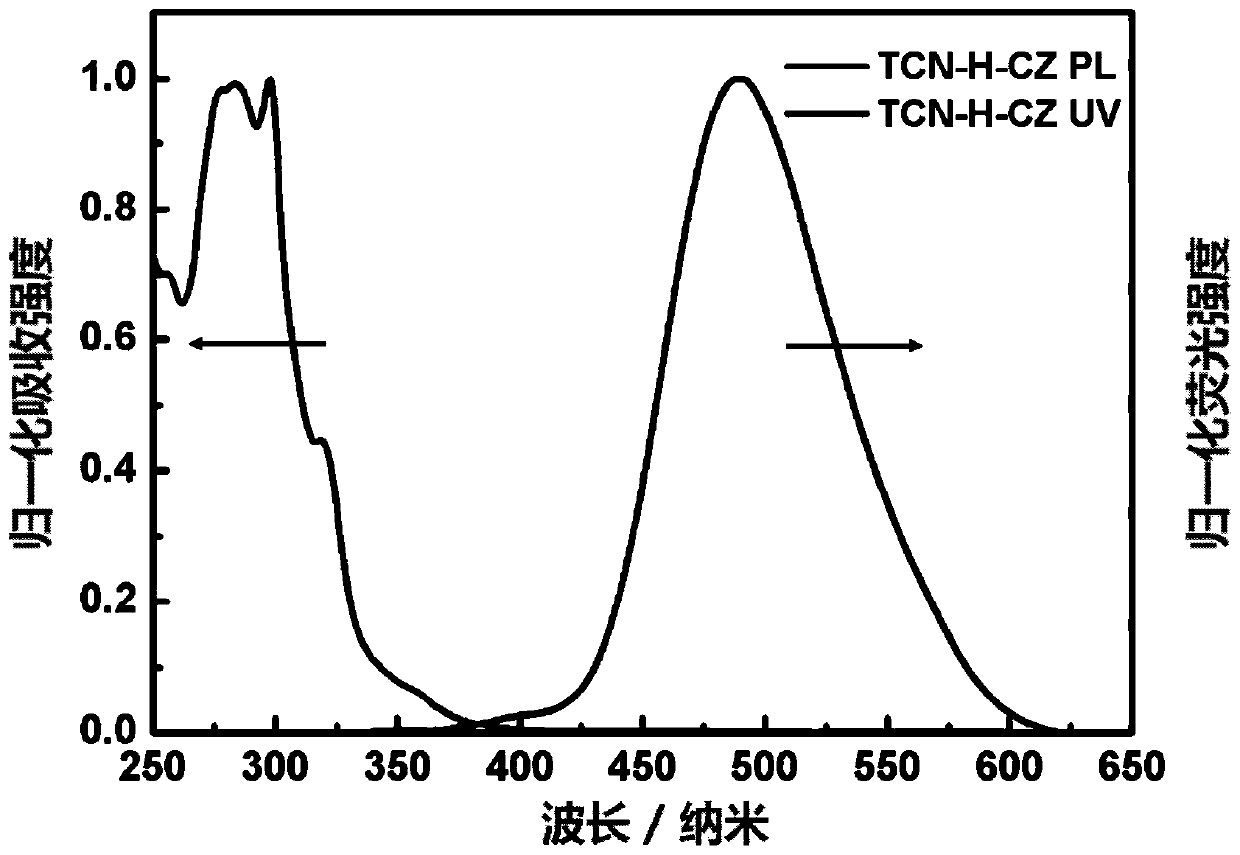

A-D-A type nano-corner lattice with thermal activation delayed fluorescence properties and preparation method and application thereof

InactiveCN110078738ASimple structureRegular structureOrganic chemistrySolid-state devicesFluorescenceSynthesis methods

The invention discloses an A-D-A type nano-corner lattice with thermal activation delayed fluorescence properties and a preparation method and the application of the A-D-A type nano-corner lattice with the thermal activation delayed fluorescence properties. The nano-corner lattice is based on fluorene or diazafluorene and has a rigid geometric structure. A-D-A type nano-corner lattice molecules exhibit cyclic characteristics and unique and excellent TADF characteristics; the A-D-A type nano-corner lattice is cheap in raw materials, easy in preparation, mild in reaction conditions and unique inperformances and high in thermal and electrochemical stability and spectral stability; the materials are novel in structure and excellent in performances and can be synthesized by an aromatic nucleophilic substitution reaction, the synthesis method is simple and the yield is high; an organic electroluminescent device can be prepared by a solution processing method and taken as a light-emitting layer material, so that the A-D-A type nano-corner lattice has the advantages of high luminous efficiency, low efficiency roll-off and capability of effectively reducing the turn-on voltage and the like. The A-D-A type nano-corner lattice disclosed by the invention is expected to become a new generation of new practical organic molecular optoelectronic materials, and has a very good application prospect in the fields of the organic electroluminescent device and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

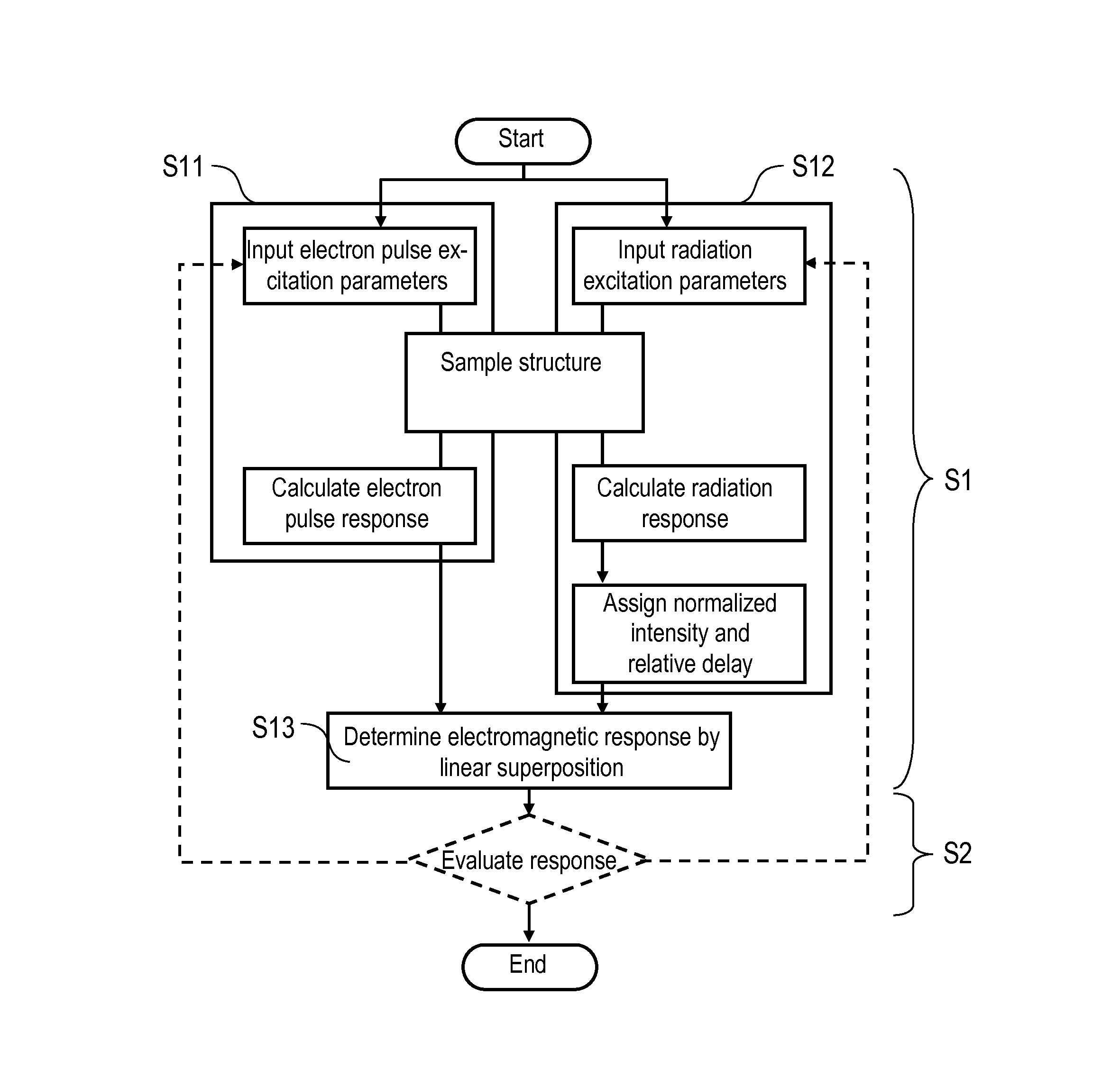

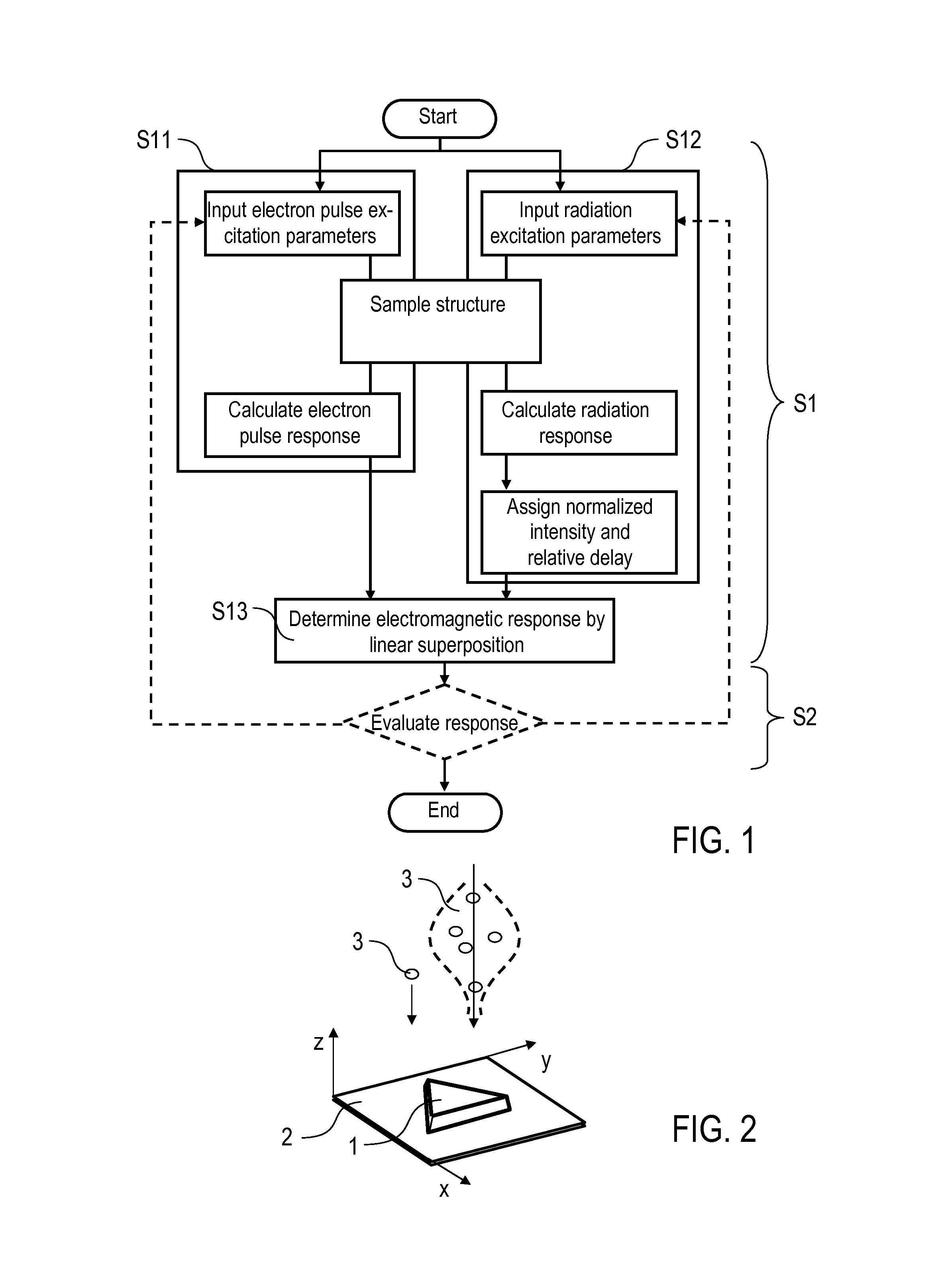

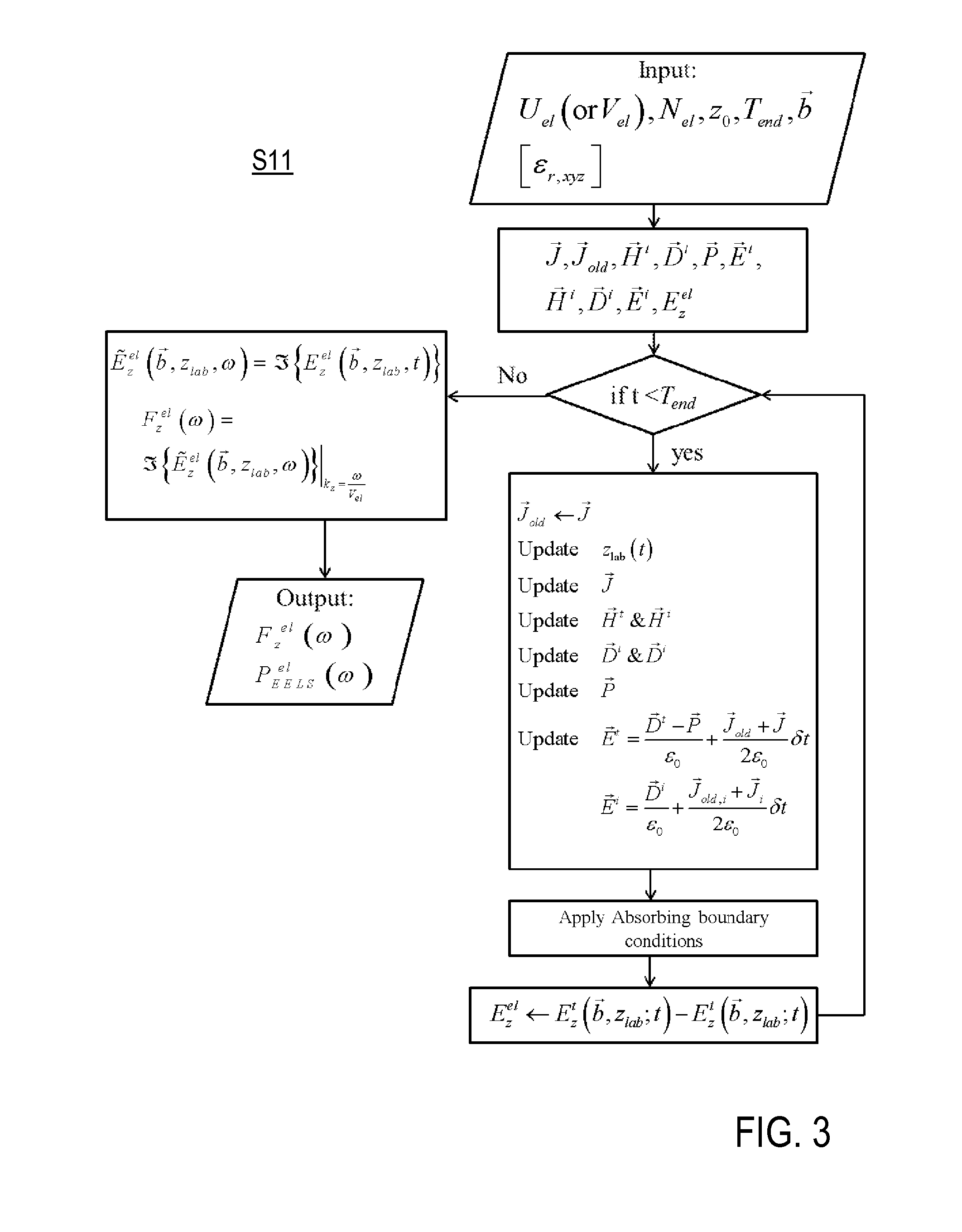

Determining an electromagnetic response of a sample

InactiveUS20140297205A1Search is time-consumeOptimization of responseMaterial analysis using wave/particle radiationElectric discharge tubesElectromagnetic responseRadiation pulse

Determining electromagnetic response of sample structure having predetermined bulk permittivity and permeability, to electron and radiation pulses, includes calculating electron pulse response of sample structure to electron pulse excitation, using finite-difference time-domain method. Electron pulse excitation is represented by non-singular current source driven by relativistic moving non-Coulombian electron charges, electron pulse response is calculated based on interaction of electron pulse excitation with electromagnetic modes of sample structure at laboratory frame, and electron pulse response depends on bulk permittivity and permeability of sample structure, calculating radiation response of sample structure to electromagnetic radiation excitation, using finite-difference time-domain method. Radiation response depends on bulk permittivity and permeability of sample structure, and providing electromagnetic response of sample structure by superimposing electron pulse response and radiation response. Electromagnetic response comprises electron-energy-loss spectra and / or experienced phase of electron wave functions after interacting with photons of electromagnetic radiation excitation. Method and measuring apparatus are also described.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

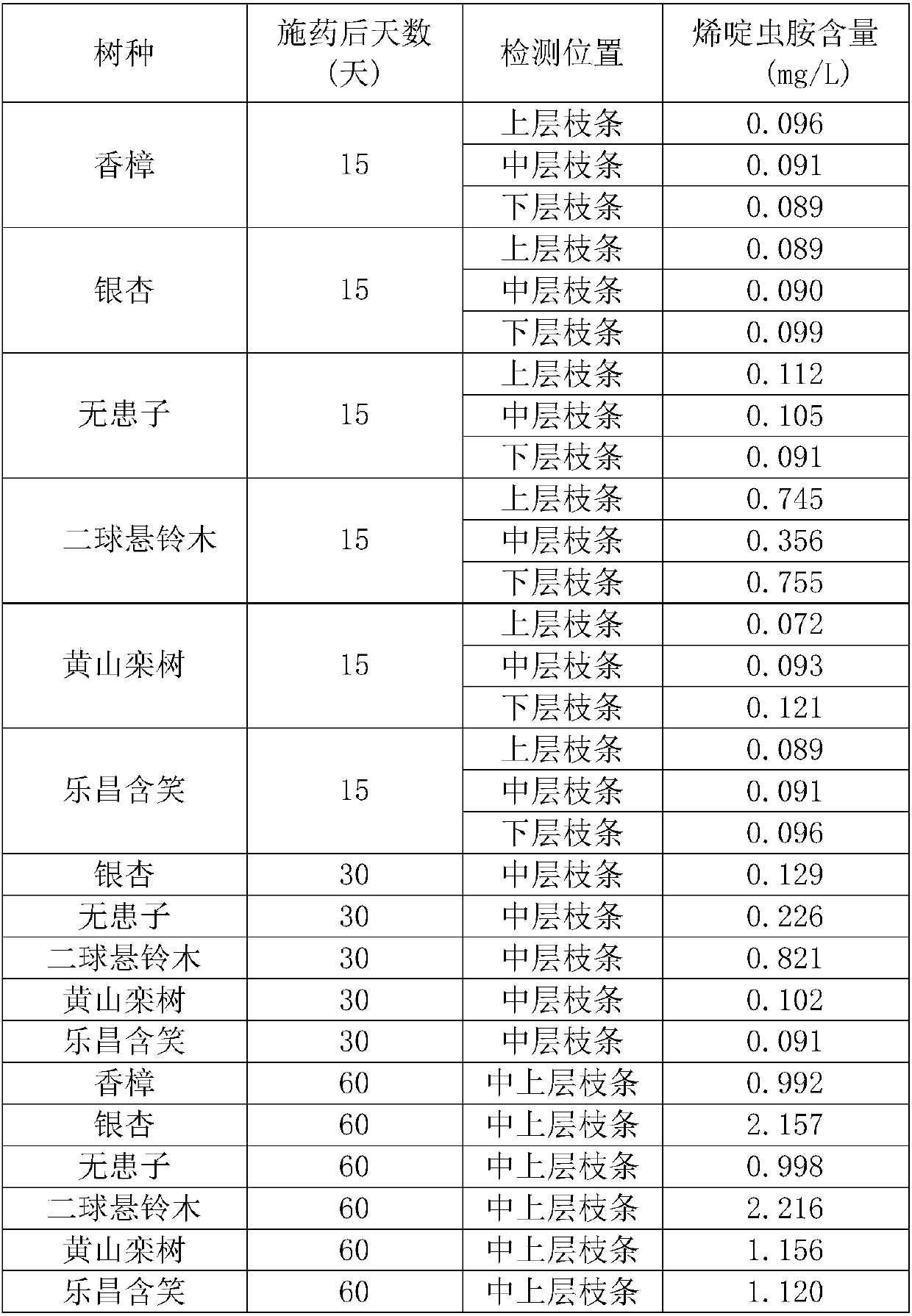

Trunk injection insecticidal micro-emulsion granules for preventing and controlling tree pests, preparation method and application thereof

The invention discloses trunk injection insecticidal micro-emulsion granules for preventing and controlling tree pests, a preparation method and an application thereof. The insecticidal micro-emulsiongranules contain the following components, by weight percent, active ingredients 9.5-12.5%, emulsifier 9.5-14.5%, co-solvent 6-8% and filler 65-72%, wherein the active ingredients are emamectin benzoate and / or neonicotinoid insecticides, and the weight percent of the above components is based on the total weight of the insecticidal micro-emulsion granules. According to the insecticidal micro-emulsion granules, a novel solid preparation is prepared by adjusting the contents of the active ingredients, the emulsifier, the co-solvent and the filler, wherein the novel solid preparation has a certain shape and good physicochemical stability, and can be effectively absorbed by plant tissues and passed to a target location by virtue of transpiration and diffusion in the tree body.

Owner:ZHEJIANG FORESTRY UNIVERSITY

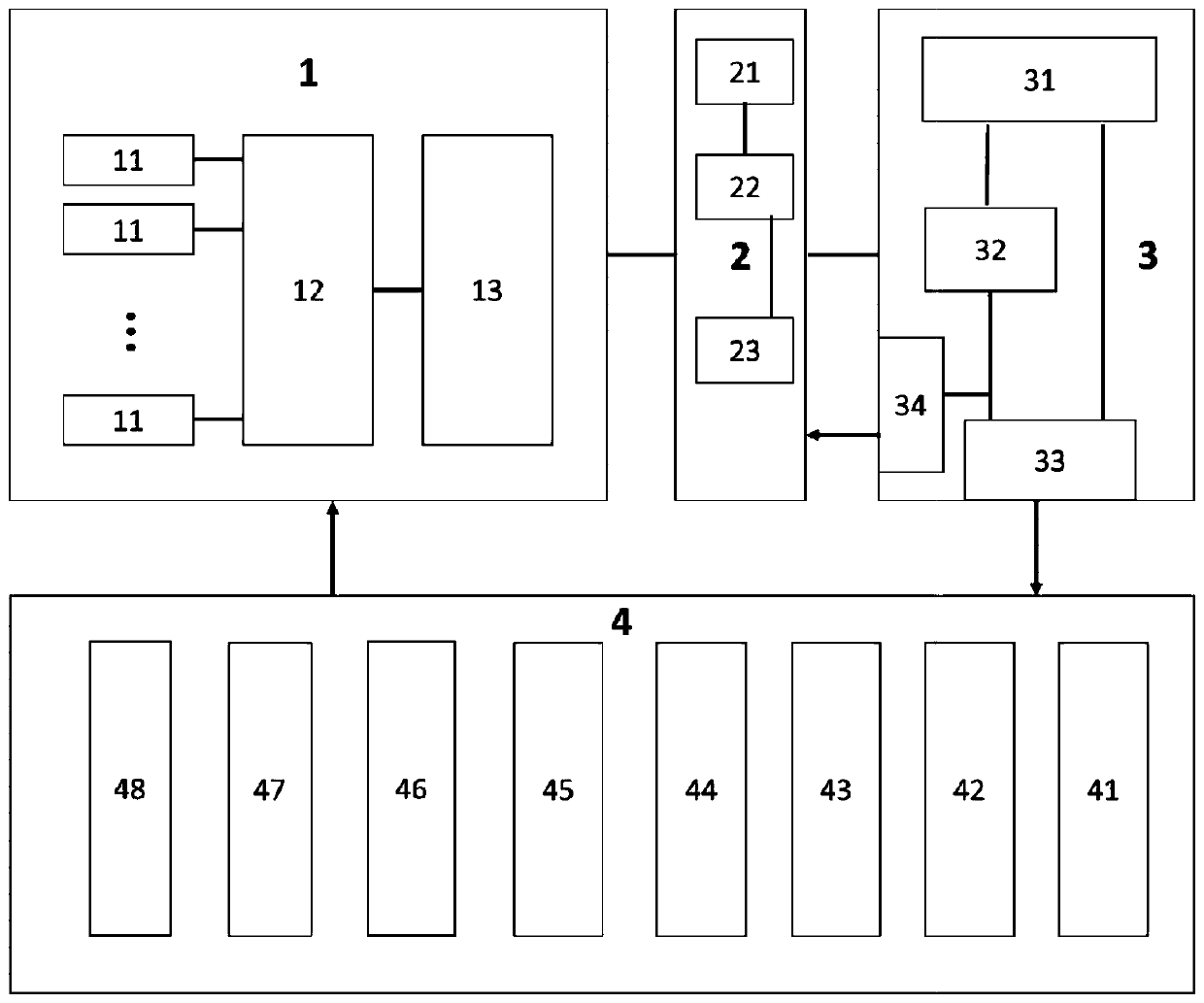

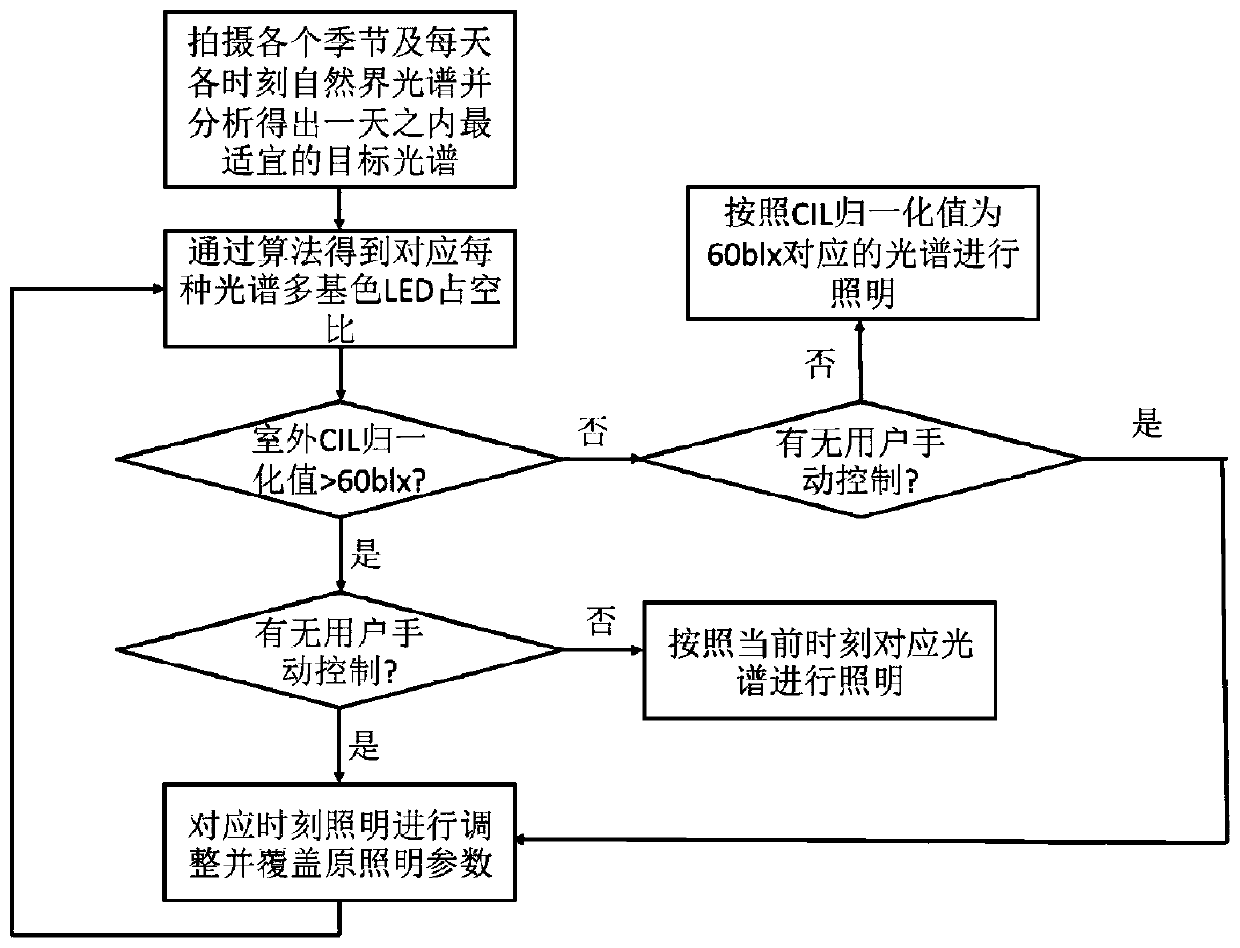

Healthy illumination system capable of effectively regulating and controlling circadian rhythm of human body

PendingCN109874195AImprove satisfactionHigh feasibilityElectrical apparatusElectroluminescent light sourcesHuman bodyMicrocomputer

The invention provides a healthy illumination system capable of effectively regulating and controlling circadian rhythm of a human body. The natural light is guided into a spectrum sensor module through a sealed reflector module to be analyzed to form a natural light spectrum, and the natural light spectrum is stored and sent to a central processing subsystem; a feedback processing module receivesthe illumination light fed back by an LED illumination subsystem and draws an illumination spectrum image to be transmitted to the central processing subsystem; a main control microcomputer module isused for classifying the natural light spectrums transmitted by a spectrum acquisition subsystem, analyzing the change tendency of circadian rhythm illumination CIL value and CAF value which are universal to natural light spectrum in one day, drawing out various target spectrum information in different time within one day by combining with the circadian rhythm curve of the human body, and simulating a target spectrum through a progressive method; and by comparing the simulated target spectrum with a lighting spectrum, the lighting spectrum is optimized to obtain a lighting spectrum closest tothe target spectrum.

Owner:XIAMEN UNIV

Tri-indene-pyrene derivative blue-light emitting material, and preparation method and application thereof

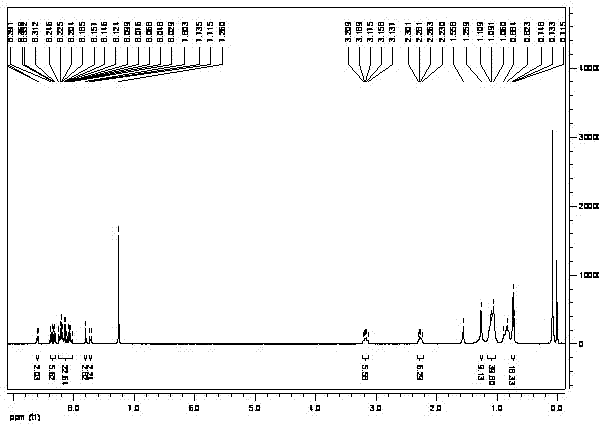

InactiveCN103242129AClear chemical structureModerate chemical structureSolid-state devicesSemiconductor/solid-state device manufacturingBlue emissionOrganic laser

The invention relates to a tri-indene-pyrene derivative blue-light emitting material, and a preparation method and application thereof. The material is a polysubstituted compound taking tri-indene as a core and seals the end by pyrene; the general formula structure is shown in the specification, wherein R is alkyl of C1-C12; the material has the characteristics that the material is simple in synthetic process, easy for volume production and easy to purify, and high chemical purity can be obtained by a simple column chromatography method; and the material displays excellent luminescence property, thermal stability, amorphous performance and spectral thermal stability when being applied as a luminescent film material, and has important application potential in the fields such organic electroluminescence and organic laser. In particular, an organic electroluminescence device using the material as the luminescent layer has efficient electroluminescent blue emission, improved color purity and excellent spectrum and apparatus stability; and the material is a blue organic electroluminescent material with practical prospect.

Owner:NANJING UNIV OF POSTS & TELECOMM

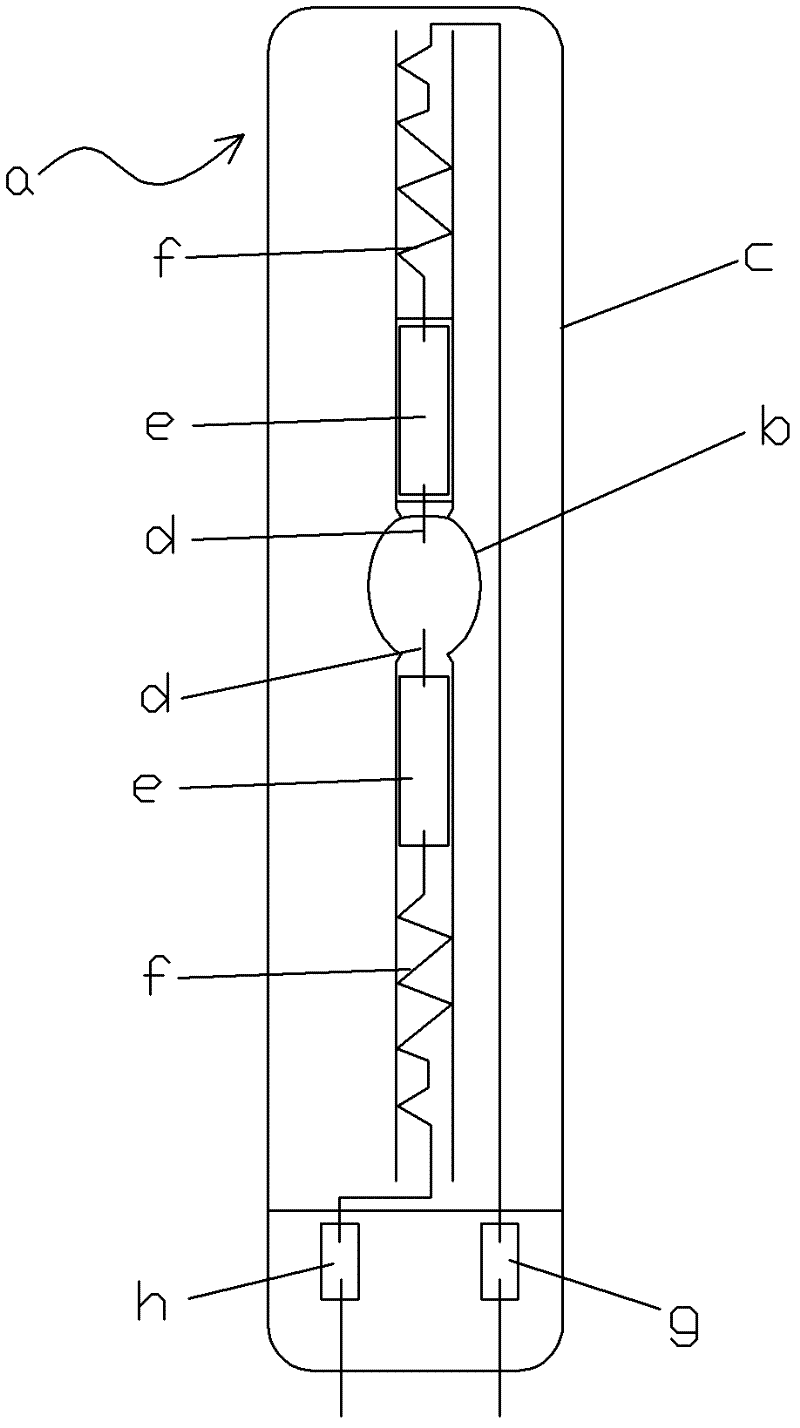

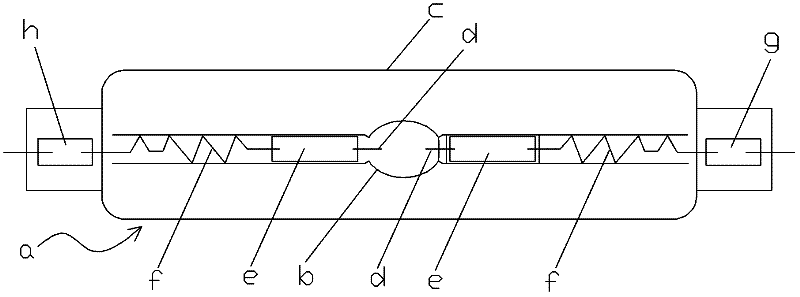

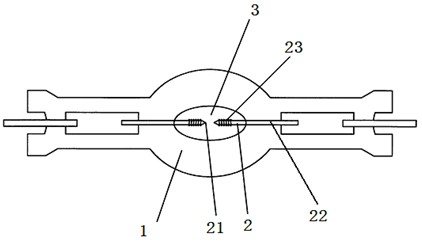

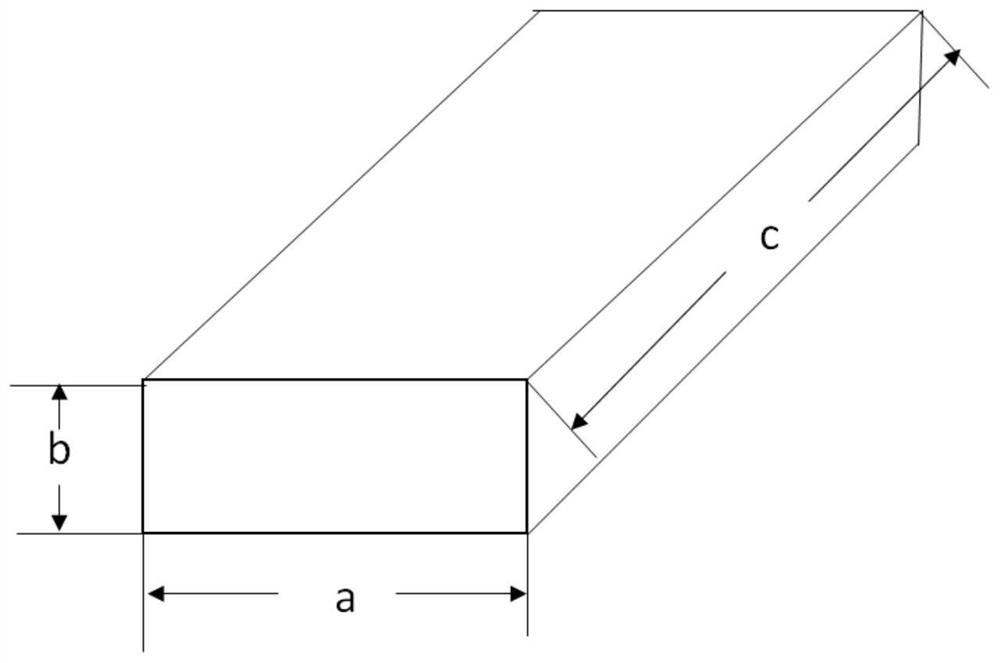

Method for manufacturing high-efficiency environment-friendly gas discharge lamp

InactiveCN102339701AOptimizing SpectrumGood colorTube/lamp vessel fillingVessels or leading-in conductors manufactureElectricityGas-discharge lamp

The invention relates to a method for manufacturing a high-efficiency environment-friendly gas discharge lamp. The method comprises the following steps of: 1, forming a ball bulb in a quartz tube; 2, filing an electrode assembly into the quartz tube, and extending one end of a thorium tungsten electrode tip to the ball bulb; 3, hooping the quartz tube and a molybdenum foil of the electrode assembly; 4, putting the quartz tube into an inert gas box with water oxygen content of not more than 1ppm, wherein the box is connected with a vacuum furnace; putting the quartz tube into the furnace, vacuumizing to 4*10<-4>Pa, heating an inner container to the temperature of between 1,000 and 1,080 DEG C, controlling an outer container to be 25 DEG C, keeping cooling, and discharging impurities; 5, taking the quartz tube out of the vacuum furnace after cooling, adding pills from the second end, and inserting a second electrode assembly into the ball bulb, wherein the second electrode assembly is coaxial with the first electrode tip; 6, connecting the second end and an extraction and filling table, vacuumizing the ball bulb to 4*10<-4>Pa, filling inert gas, and sealing the second end; 7, making the second end of the quartz tube upward, inserting the quartz tube into liquid nitrogen, liquefying the inert gas to the ball bulb, and inserting the quartz tube into a pressing sealer with a liquid nitrogen tank; and 8, making the quartz tube form a conductive connector, and pressing and sealing the quartz tube on an outer cover, wherein the two electrode assemblies are electrically connected with a conductive assembly respectively.

Owner:浙江拜克光电技术有限公司

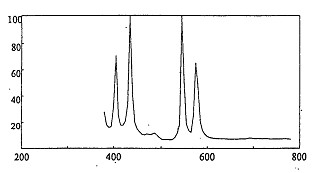

Ultrahigh-voltage metal halogen and mercury lamp

ActiveCN102163534AReduce erosionIncreased red light spectrumGas discharge lamp detailsLithiumHalogen

The invention discloses an ultrahigh-voltage metal halogen and mercury lamp. The ultrahigh-voltage metal halogen and mercury lamp comprises a lamp body and an electrode; a lamp cavity is formed inside the lamp body; the electrode extends into the lamp cavity; mercury and mercury halide are filled inside the lamp cavity; and one or a combination of gallium halide, lithium halide, zinc halide, arrowhead halide and scandium halide is filled inside the lamp cavity. In the ultrahigh-voltage gold, halogen and mercury lamp, the metal halide is added into the lamp cavity; the electrode head is configured to be a conical tip head to form tip-end discharging, so the red light spectrum can be increased, the blue light spectrum can be enhanced, and the three base colors, namely red, blue and green, tend to balance; therefore, the light color is improved and the brightness is enhanced. Moreover, by limiting the percentage composition of the metal halide, the light color can be further improved, the brightness and the lighting effect can be enhanced, and the problem that the lamp may be blasted under ultrahigh voltage can be avoided effectively.

Owner:SHANGHAI HAOYE OPTOELECTRONICS TECH

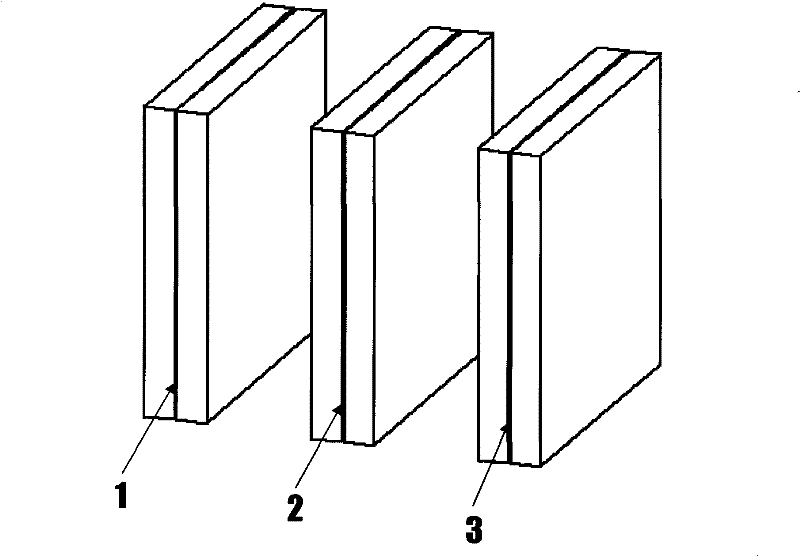

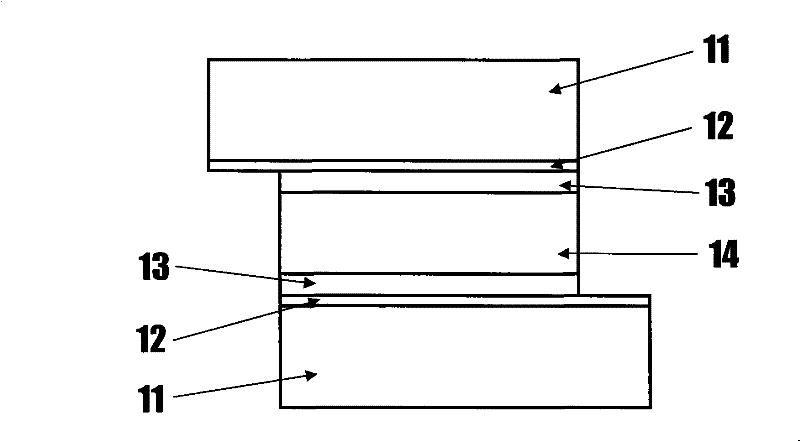

Third level Fabry-Perot cavity type tunable ray filter system

InactiveCN101533159BThe preparation process is matureWide filter spectrumNon-linear opticsImage resolutionFilter system

The invention discloses a third level Fabry-Perot cavity type tunable ray filter system, comprising two structures. The first structure comprises three Fabry-Perot cavities, wherein, the Fabry-Perot cavities are electrically tunable; the second structure comprises a polarizer, the three Fabry-Perot cavities and an analyzer, wherein, the Fabry-Perot cavities have the tunable effect only on the linearly polarized light which goes through the polarizer. The invention realizes continuously adjustable narrowband light-filtering within the wide spectral range by the reasonable design of the three Fabry-Perot cavities, the Fabry-Perot cavities have mature fabrication process, and the implementation of the whole system is convenient. The invention further has the characteristics of large aperture, simple assembling, wide light-filtering spectrum range and high spectral resolution, and can be applied in the fields of remote sensing, biomedicine, astronomical observation and the like.

Owner:ZHEJIANG UNIV

Spirofluorenexanthene type electron transport material and preparation method and application thereof

InactiveCN109796442AGood thermal, electrochemicalImprove stabilityOrganic chemistrySolid-state devicesOptical propertyActive site

The invention discloses a spirofluorenexanthene type electron transport material and a preparation method and application thereof. Active sites on a skeleton of fluorene and xanthene can be introducedinto photoelectric active groups, and are easy to modify without changing a cross structure, so that electron-transport is facilitated. The spirofluorenexanthene type electron transport material hasgood thermal, electrochemical and spectral stability by means of the cross structure, and the optical property and the electrical property can be achieved by changing the photoactive active groups. Therefore, the spirofluorenexanthene type electron transport material has good application prospects in the field of organic photoelectricity.

Owner:NANJING UNIV OF POSTS & TELECOMM

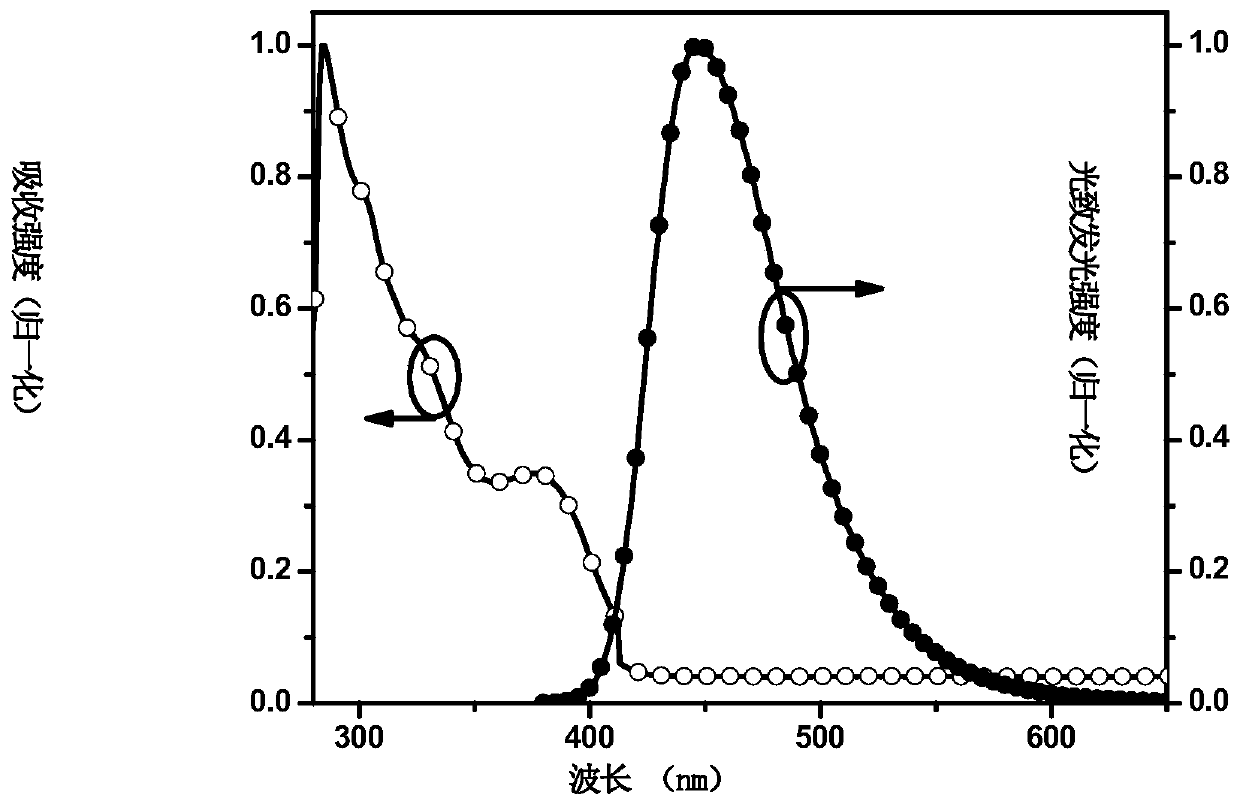

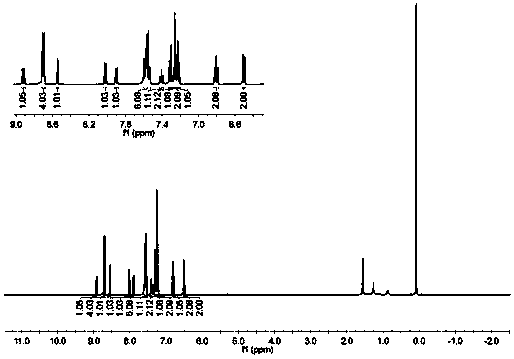

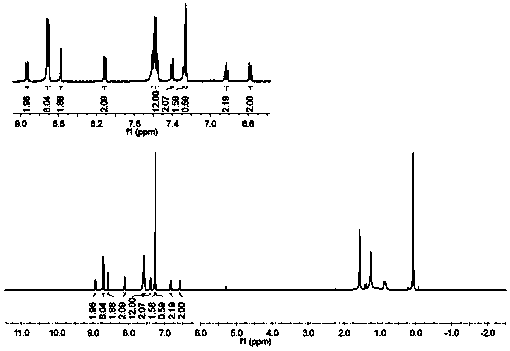

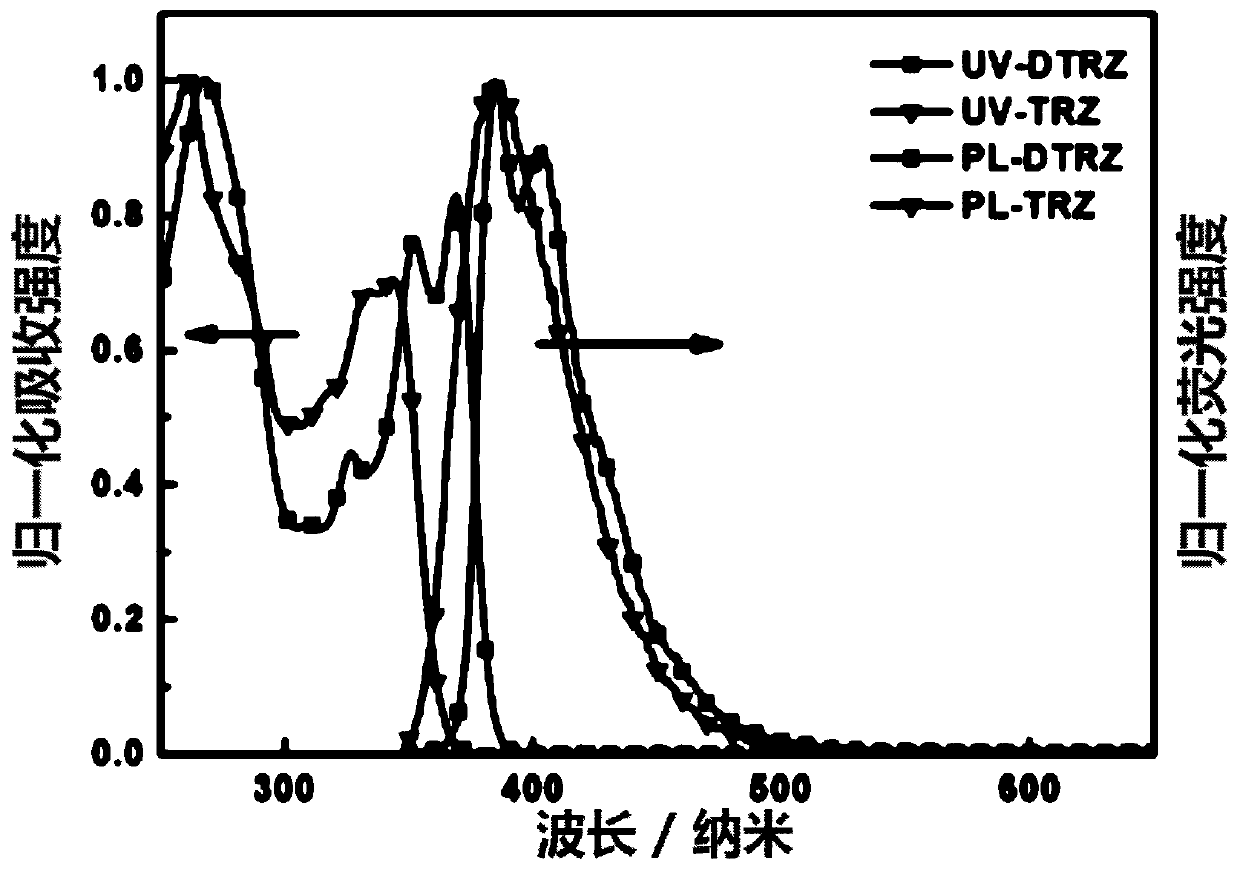

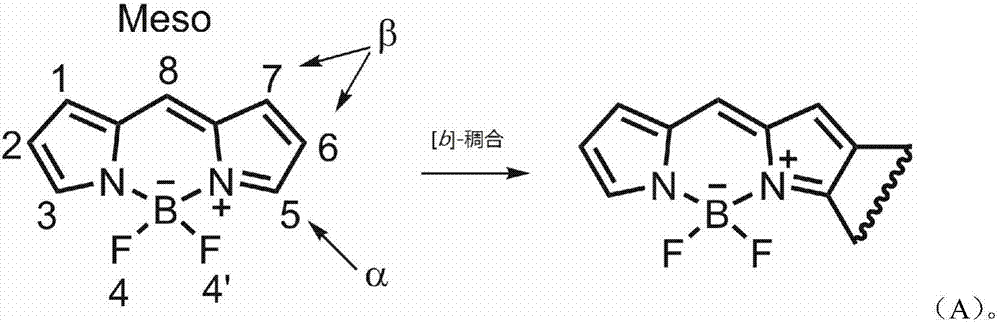

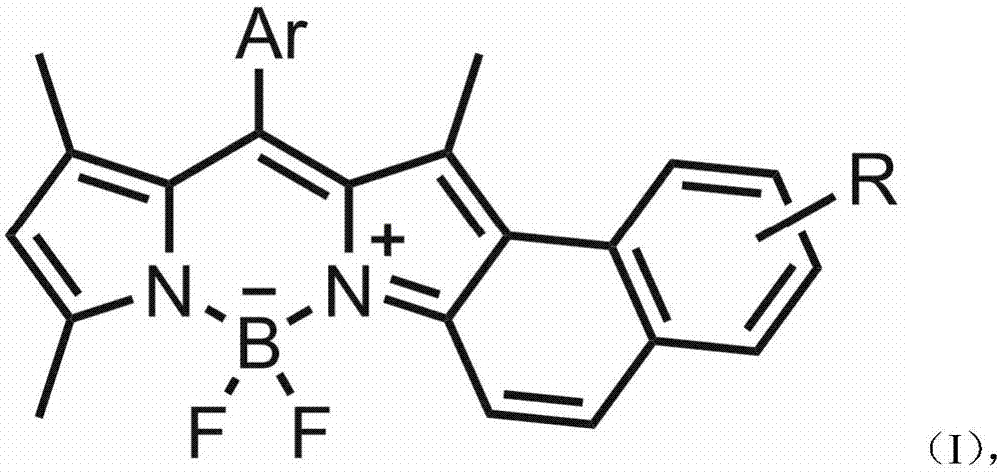

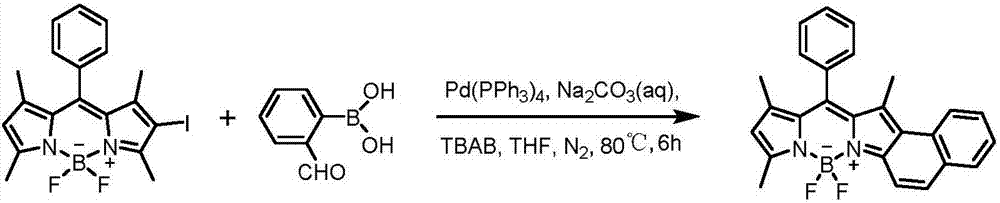

Asymmetric naphthalene ring fused boron dipyrromethene fluorescent dye and preparation method thereof

ActiveCN106946918AExtended π orbitalConducive to delocalizationAzo dyesGroup 3/13 element organic compoundsFuranFluorescence

The invention belongs to the technical fields of fine chemical industry and organic synthesis, and concretely relates to an asymmetric naphthalene ring fused boron dipyrromethene fluorescent dye and a preparation method thereof. The asymmetric naphthalene ring fused boron dipyrromethene fluorescent dye has a structure represented by formula (I) shown in the description; and in the formula (I), Ar is selected from a phenyl group, a substituted phenyl group, a thienyl group, a substituted thienyl group, a furyl group and a substituted furyl group, and R is selected from a methyl group, a methoxy group and a fluoro group. The asymmetric naphthalene ring fused boron dipyrromethene fluorescent dye has the advantages of simple synthesis method, convenience in separation, and high yield, also has excellent spectral properties, such as high molar extinction coefficient and strong fluorescence emission, in order to realize high light stability, and can be further modified to form a molecular probe.

Owner:JIANGSU UNIV OF SCI & TECH

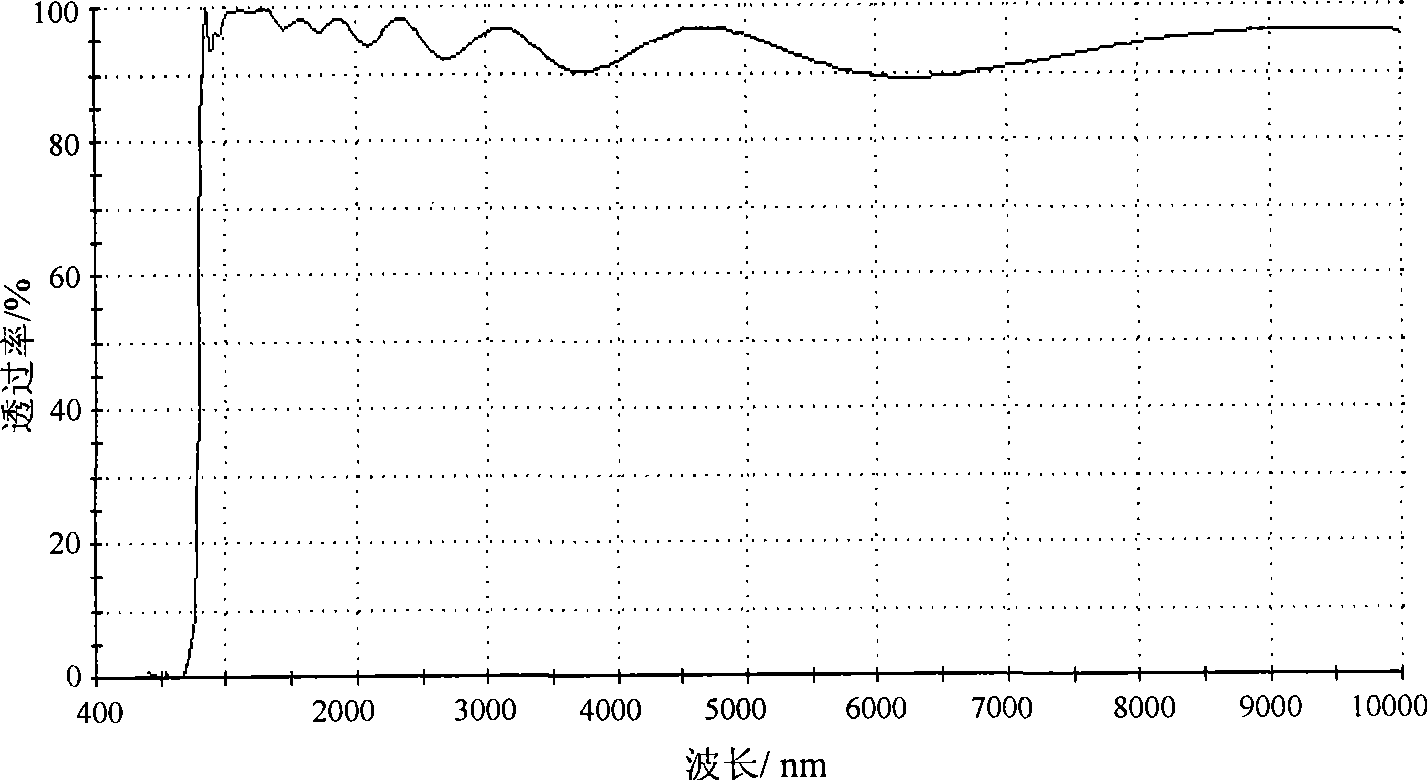

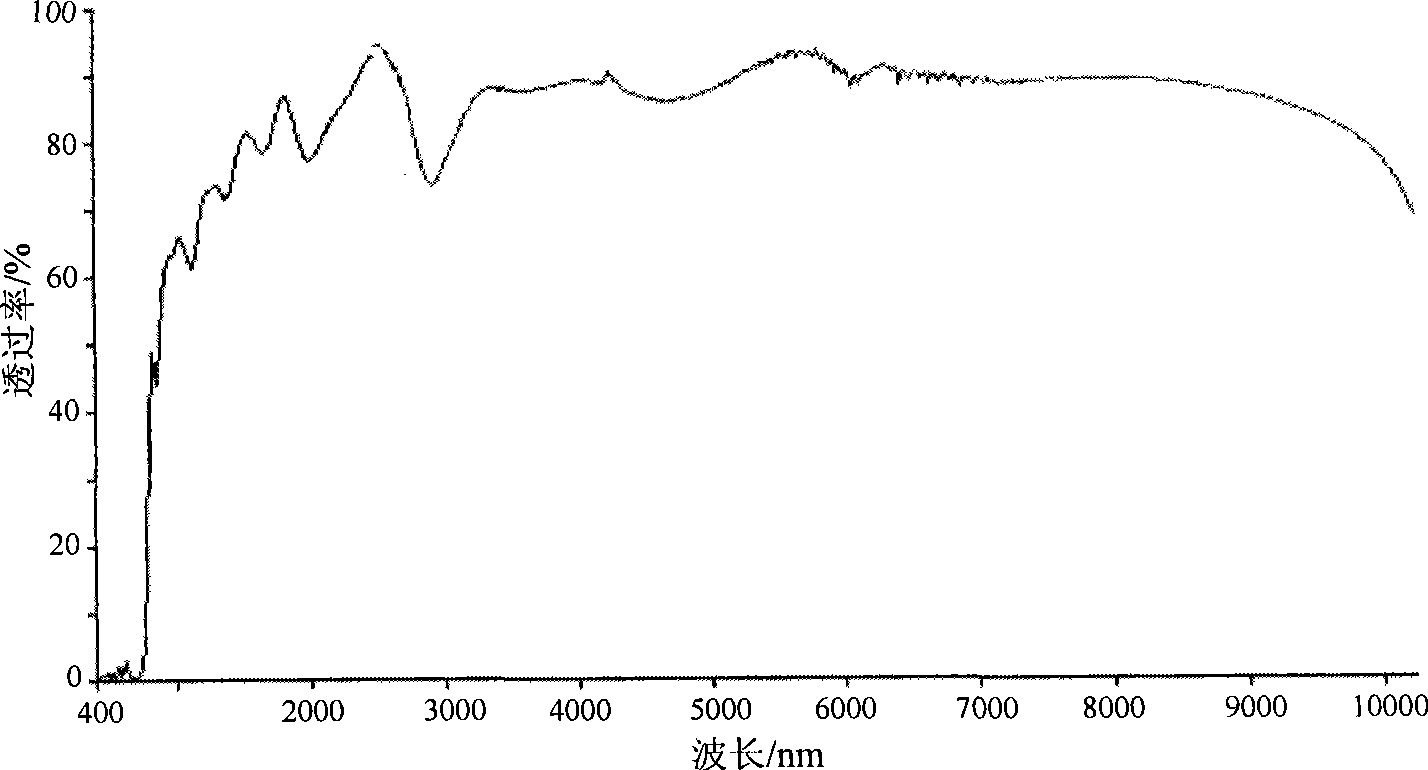

0.4-10.0 micrometer ultra-wide spectrum dichroic filter

InactiveCN101470265AImprove reflectivityWide spectral rangeOptical elementsMicrometerRefractive index

The invention discloses a 0.4-10.0 microns ultra-wide spectrum dichroic mirror. The ultra-wide spectrum dichroic mirror utilizes barium fluoride as a film coating substrate, utilizes titanium dioxide and cryolite as film coating materials, and expands a reflecting belt through overlapping a plurality of long-wave passed film systems with different wave lengths. A design film system of the ultra-wide spectrum dichroic mirror is BaF2 / 1.2(0.5HL0.5H)5(0.5HL0.5H)5 / 0.8(0.5HL0.5H)5 / 2L / Air, wherein the H and L are respectively 1 / 4 wave-length optical thicknesses of a high refractive index material and a low refractive index material, and the center wave-length is 550nm, the result proves that the average reflectance of the ultra-wide dichroic mirror is 98.93% in the waveband of 0.4-0.748 mu m, and the average transmittance is 86.64% in the waveband of 1.5-10.0 mu m. The ultra-wide spectrum dichroic mirror has the advantages of high reflectance in a reflecting area, wide spectrum range in the reflecting area, changing fast from the reflecting area to a transmitting area, high transmittance in the transmitting area, and having excellent spectra and mechanics stability. Further, the invention can be applied to optical systems in the field of spectroanalysis instruments, projecting cameras, special illuminating devices, television cameras, aerospace engineering and the like.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

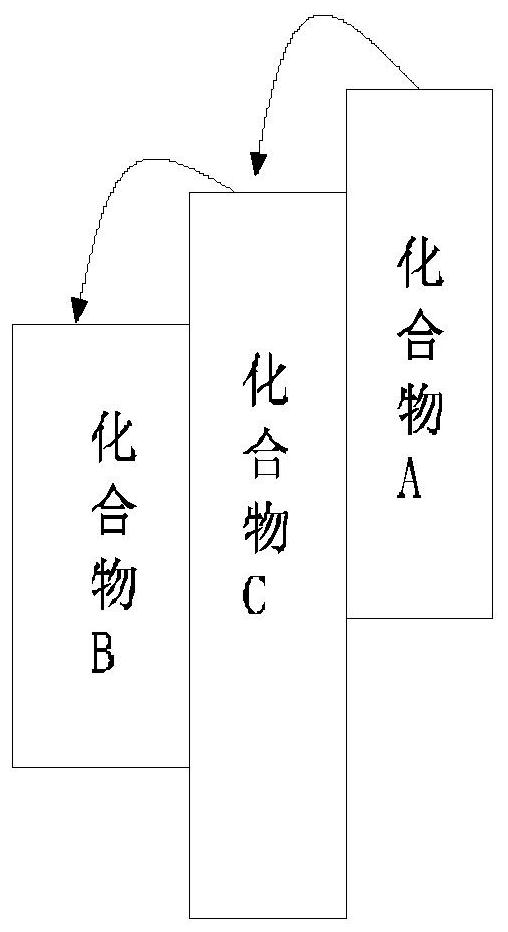

Light-emitting display device and preparation method thereof and display device

PendingCN111785858AAvoid quenchingImprove external quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a light-emitting display device and a preparation method thereof and a display device. The light-emitting display device comprises a cathode, an anode and a light-emitting layerlocated between the cathode and the anode. The light-emitting layer at least comprises a compound A, a compound B and a compound C, the compound A and the compound B are compounded to form an exciplex, the compound C is used as a host compound, and the exciplex is dispersed in the compound C.

Owner:BOE TECH GRP CO LTD

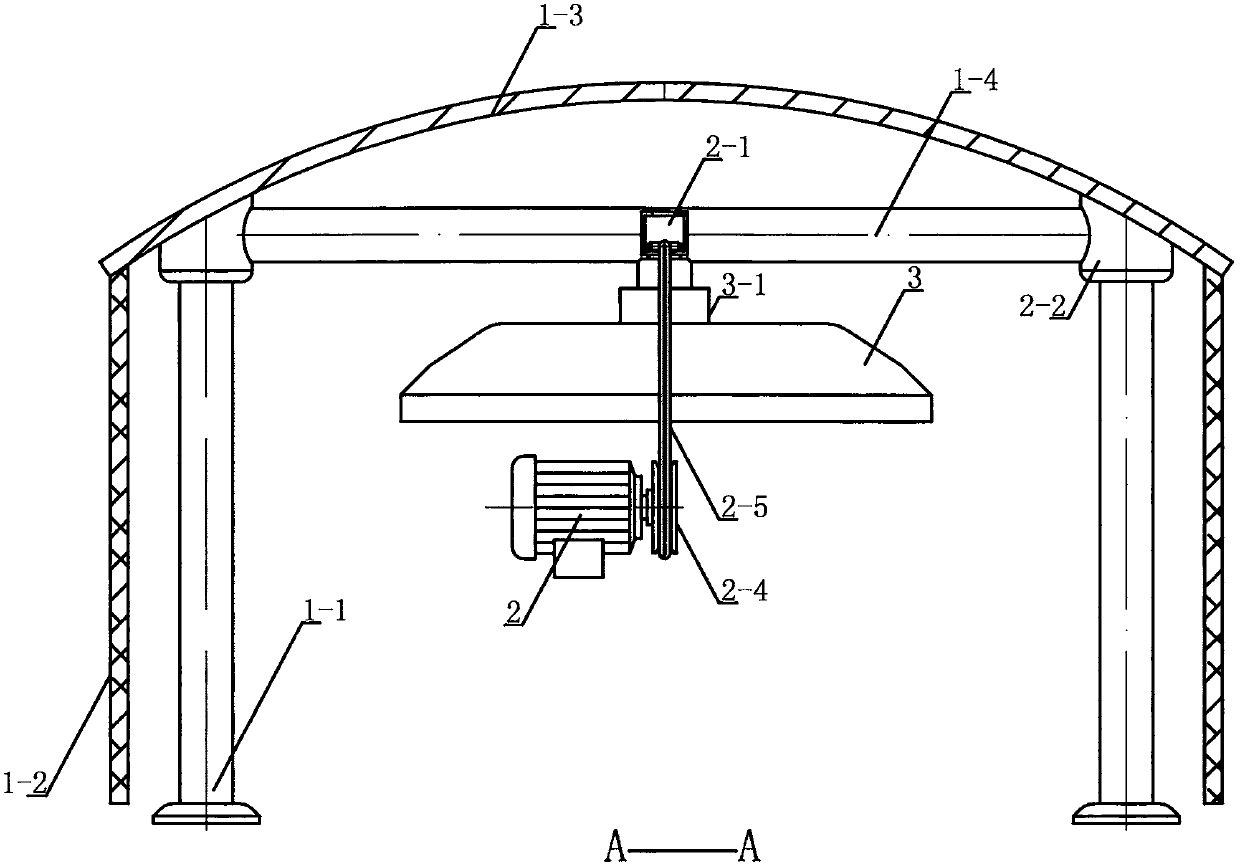

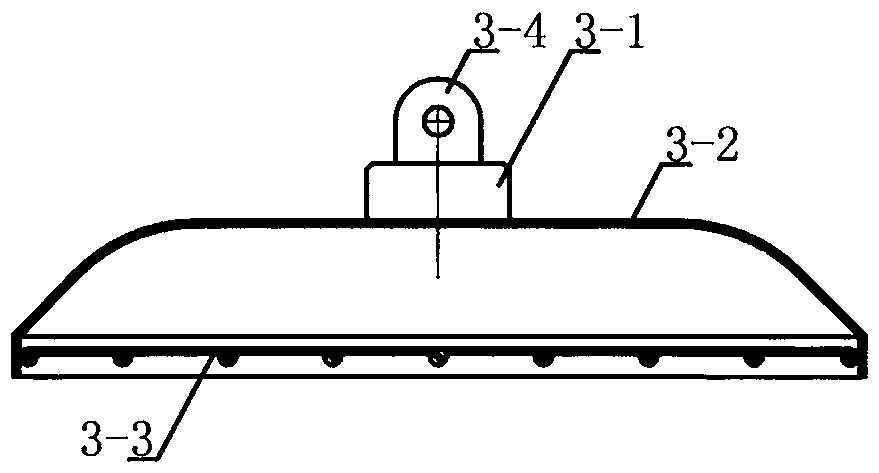

Controllable spectral plant cultivation greenhouse

InactiveCN109548523AImprove qualityIncrease harvestClimate change adaptationGreenhouse cultivationEnergy technologyGreenhouse

The invention discloses a controllable spectral plant cultivation greenhouse, which mainly consists of vertical columns, chapiter woods, a beam, a greenhouse wall, a greenhouse top cover, a cloud rail, a speed reduction motor, a pull rope, a spectral radiance holder, a rope buckle ring, a built-in ratchet wheel mechanism rope winding plate, a pull rope, a spectral radiance holder and a lifting threaded seat, wherein the beam is mounted between the chapiter woods to form frames; the cloud rail is mounted on the beam between the two frames; rolling sleeves mounted in a radial direction of hanging shafts above the spectral radiance holder are embedded into two sides of a sliding chute of the cloud rail; the spectral radiance holder can select infrared spectral radiance or blue ray spectral radiance in combination with a growing rule of crops, and a holder traction mechanism is controlled to adjust a cloud rail motion state according to requirements for plant radiance time and frequency; asolar photovaltaic energy technology and a lithium battery energy storage technology are adopted to promote quality improvement and yield increase of the crops without increasing carbon discharging.

Owner:王敏 +1

H-Shape cyanation opto-electric transmission type material and preparation method and application thereof

InactiveCN109761878AImprove performanceImprove stabilityOrganic chemistrySolid-state devicesHost materialEngineering

The invention discloses an H-Shape cyanidation opto-electric transmission type material and a preparation method and application thereof. Double-spiro fluorenyl is connected with a core (Ar1) by sp<3>carbon, an ''H'' structure is exhibited in space, and the cyanation is performed on fluorenyl two arms to facilitate electron or hole transmission. Due to the introduction of classical electron-withdrawing cyano-based fragments, the transmission material of the type has certain electron / hole transmission properties and can be used as a host material in the field of photovoltaic materials. The preparation method of the H-Shape cyanidation material which exhibits the ''H'' shape in space and has excellent performance is provided, the H-Shape cyanidation material of the type can further regulatethe ability of accepting receptors by regulating the number of cyano groups, molecular energy levels are regulated, good solution-processable opto-electric transmission materials are achieved, good stability in terms of electrochemistry, thermal and spectrum is achieved, and the H-Shape cyanidation opto-electric transmission type material is a kind of material with good application prospects in the field of opto-electric transmission.

Owner:NANJING UNIV OF POSTS & TELECOMM

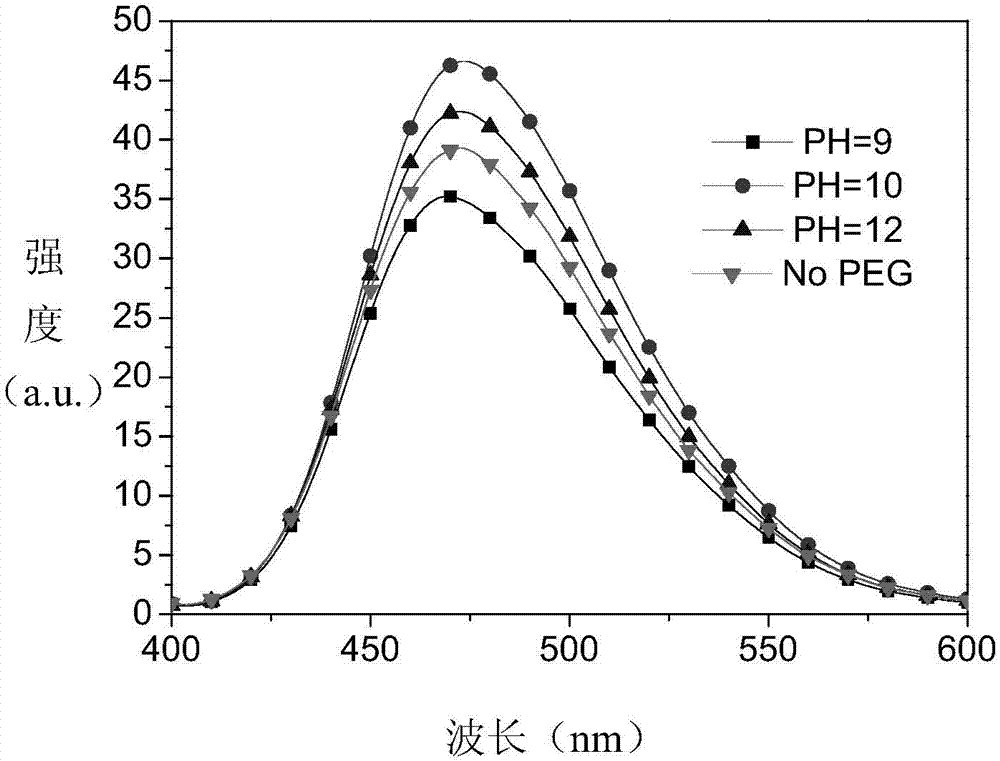

Fluorescent powder preparation method based on polyethylene glycol and with ethanol as solvent

InactiveCN104745181AHigh diffraction peakNo miscellaneous peaksLuminescent compositionsWater bathsPolyethylene glycol

The invention discloses a fluorescent powder preparation method based on polyethylene glycol and with ethanol as solvent, and belongs to the field of preparation of fluorescent powder. By utilizing sol gel combustion method, with polyethylene glycol (PEG) as dispersing agent, absolute ethyl alcohol as solvent and incendiary agent, urea as complexing agent and reducing agent, and nitrate as oxidant, through introducing fluxing agent boric acid, dissolving into absolute ethyl alcohol together with metal nitrate, heating in a water bath to form sol, cooling to obtain white gel, then heating the gel in a Muffle furnace until the gel burns spontaneously to form fluffy powder, cooling and grinding, so as to obtain fluorescent powder. The method is simple in process, free in pollution, low in synthesis temperature, short in reaction time, low in cost, low in energy consumption and high in quenching concentration; by utilizing surface dispersing agent PEG and solvent ethyl alcohol, the products are prevented from gathering, the dispersion property of the fluorescent powder and the evenness of particle size are improved, the fluorescent powder has excellent light emitting strength, and therefore the prepared fluorescent powder is better applicable for LED (light emitting diode) products.

Owner:LONGTENG LIGHTING GRP +1

Photoelectric conversion element, solid-state imaging device, and electronic apparatus

ActiveUS11349092B2Improve photoelectric conversion efficiencyReduce interactionTelevision system detailsSolid-state devicesPhotoelectric conversionOrganic semiconductor

A photoelectric conversion element according to an embodiment of the disclosure includes a first electrode and a second electrode, and an organic semiconductor layer. The first electrode and the second electrode are disposed to face each other. The organic semiconductor layer is provided between the first electrode and the second electrode, and contains a fullerene derivative modified by a substituent having an absorbance smaller than that of a fullerene.

Owner:SONY SEMICON SOLUTIONS CORP

A method for realizing no mode hopping in semiconductor laser chip wave locking

ActiveCN111740310BOptimizing SpectrumSimple technical meansLaser detailsSemiconductor lasersErbium lasersHeat sink

The invention provides a method for realizing no mode-hopping in the wave-locking of a semiconductor laser chip, and solves the phenomenon of film-hopping in the spectrum of the existing single-tube chip, and this phenomenon will cause the problem that the wave-locking cannot be performed during the VBG wave-locking process. The method of the present invention includes the following steps: step 1, setting a plurality of grooves on the upper surface of the auxiliary heat sink, and the plurality of grooves are equidistantly arranged; step 2, mounting the ceramic heat sink with a single-tube chip on the auxiliary heat sink The upper surface of the heat sink; step 3, installing the auxiliary heat sink on the components of the optical fiber. At the same time, the mode-hop-free semiconductor laser of the present invention includes a single-tube chip, a ceramic heat sink, and an auxiliary heat sink that are stacked in sequence. The surface of the auxiliary heat sink and the ceramic heat sink is provided with multiple grooves, and the multiple grooves distance setting. The method of the present invention carries out groove design on the auxiliary heat sink, and the groove can release stress when the COS is mounted on the auxiliary heat sink to obtain a better spectrum, and then VBG wave locking can be performed.

Owner:XIAN LIXIN PHOTOELECTRIC SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com