Method for manufacturing high-efficiency environment-friendly gas discharge lamp

A technology for gas discharge lamps and manufacturing methods, which is applied in the manufacture of discharge tubes/lamps, electrode systems, ships or lead-in wires, etc., and can solve problems such as low service life, poor color temperature consistency, and large amount of mercury injection. Achieve the effect of long service life, good consistency and less mercury injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below.

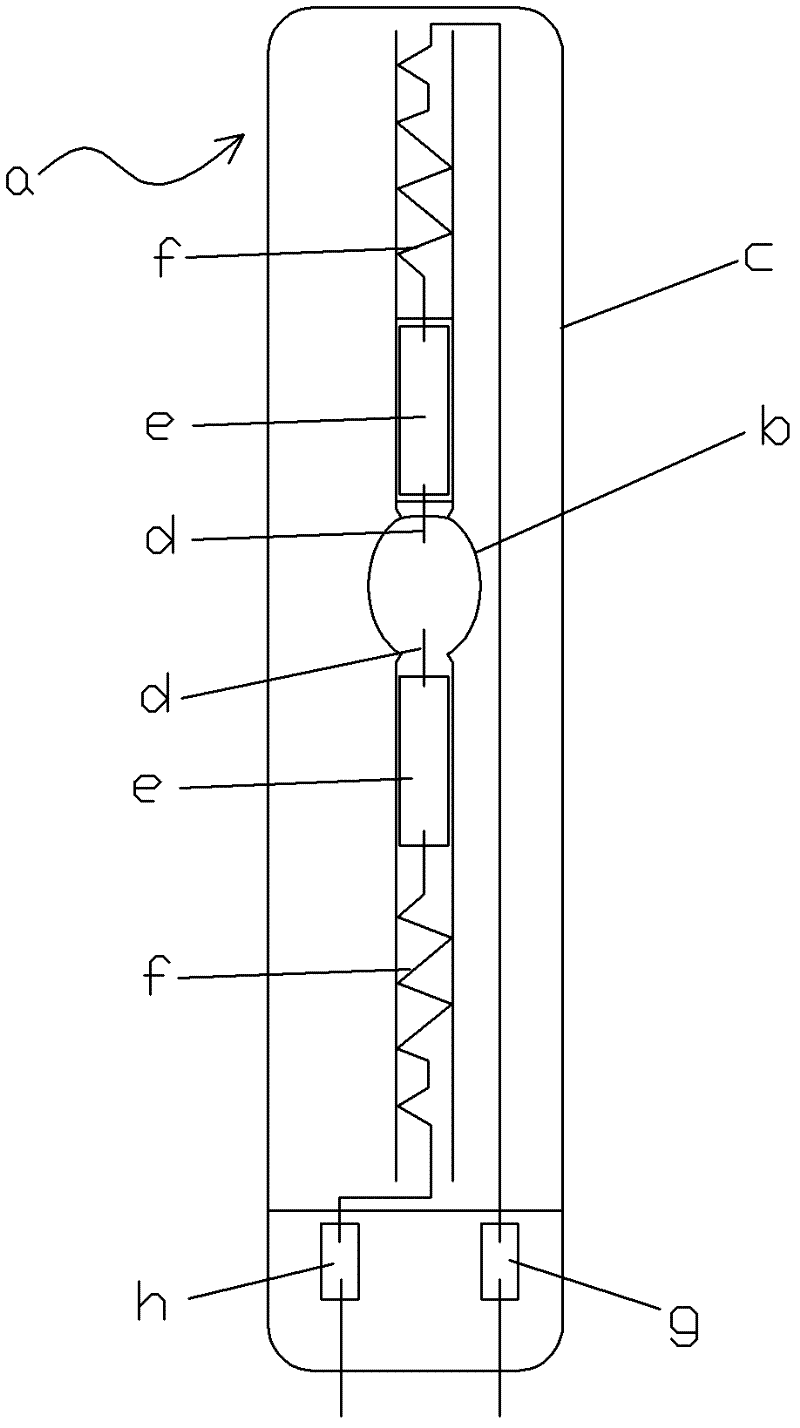

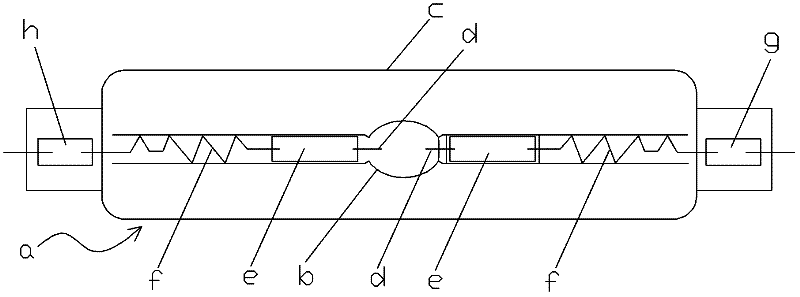

[0023] figure 1 , figure 2 Two gas discharge lamps with different constructions of the protective cover are shown respectively, the principle of which is the same for both gas discharge lamps. see figure 1 , 2 The high-efficiency and environment-friendly gas discharge lamp a of the present invention has an external protective cover c, a discharge vessel b, and two electrode assemblies. The electrode assembly is composed of a thoriated tungsten alloy electrode head d, molybdenum foil e, and molybdenum wire f connected in sequence. The discharge vessel b is olive-shaped, and it is inside the protective cover c. The thoriated tungsten alloy electrode heads a of the two electrode assemblies protrude from both ends of the discharge vessel b into the interior respectively, and provide electricity for the discharge vessel b through the two electrode assemblies. The other ends of the molybdenum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com