Fluorescent powder preparation method based on polyethylene glycol and with ethanol as solvent

A polyethylene glycol and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor particle size uniformity, poor dispersion of phosphor powder, agglomeration, etc., and achieve improved luminous intensity, convenient operation, and improved dispersion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

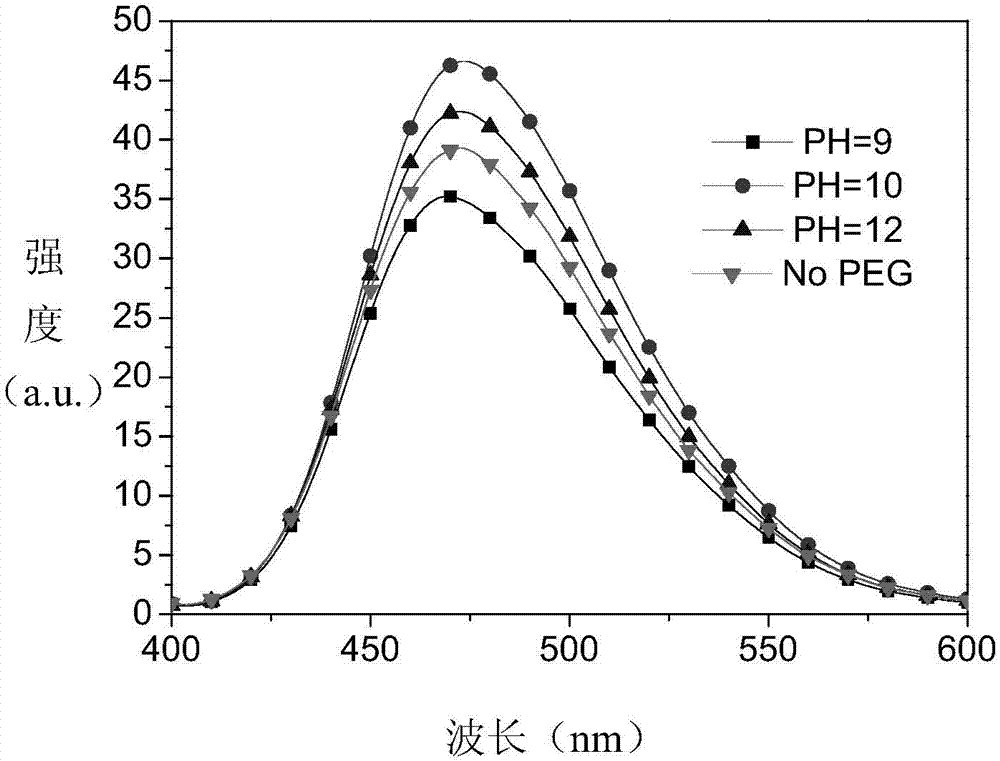

[0031] Accurately weigh 7.5027g Al(NO 3 ) 3 9H 2 O, 0.2681g Sr(NO 3 ) 2 , 0.1655g Ba(NO 3 ) 2 , 0.5128g Mg(NO 3 ) 2 ·6H 2 O, 0.0176g Eu 2 o 3 ; Press nitrate (0.024mol): urea is to add urea in the molar ratio of 1:1.5 again, press nitrate (0.024mol): boric acid is to add boric acid in the molar ratio of 100:1, press concentrated nitric acid: Sr x Ba y Ca 1-x-y Mg z Zn 1-z al 10 o 17 :Eu 2+ (0.002mol) added concentrated nitric acid in a molar ratio of 5:1, according to absolute ethanol:Sr x Ba y Ca 1-x-y Mg z Zn 1-z al 10 o 17 :Eu 2+ (0.002mol) is added absolute ethanol at a molar ratio of 8:1, and the amount of polyethylene glycol added is 0.5% by mass percent of the total mass of nitrates. Will Eu 2 o 3 Dissolve in concentrated nitric acid (mass fraction 65%), then add absolute ethanol, then add polyethylene glycol (number average molecular weight 1200) to adjust the pH to 10, then add the required nitrate to obtain a transparent solution, then add ...

Embodiment 2

[0033] Accurately weigh 7.5027g Al(NO 3 ) 3 9H 2 O, 0.3217g Sr(NO 3 ) 2 , 0.0993g Ba(NO 3 ) 2 , 0.5128g Mg(NO 3 ) 2 ·6H 2 O, 0.0176g Eu 2 o 3 ,; Add urea again by nitrate (0.024mol): urea is 1:1.5 molar ratio, by nitrate (0.024mol): boric acid is 100:1 molar ratio to add boric acid, press concentrated nitric acid: Sr x Ba y Ca 1-x-y Mg z Zn 1-z al 10 o 17 :Eu 2+ (0.002mol) added concentrated nitric acid in a molar ratio of 5:1, according to absolute ethanol:Sr x Ba y Ca 1-x-y Mg z Zn 1-z al 10 o 17 :Eu 2+ (0.002mol) is added absolute ethanol at a molar ratio of 8:1, and the addition amount of polyethylene glycol is 0.5% by mass percentage. Will Eu 2 o 3 Dissolve in concentrated nitric acid (mass fraction 65%), then add absolute ethanol, then add polyethylene glycol (number average molecular weight 1200) to adjust the pH to 10, then add the required nitrate to obtain a transparent solution, then add boric acid and urea Stir continuously to obtain the...

Embodiment 3

[0035] Accurately weigh 7.5027g Al(NO 3 ) 3 9H 2 O, 0.1340g Sr(NO 3 ) 2 , 0.3310g Ba(NO 3 ) 2 , 0.5128g Mg(NO 3 ) 2 ·6H 2 O, 0.0176g Eu 2 o 3 ,; Add urea again by nitrate (0.024mol): urea is 1:1.5 molar ratio, by nitrate (0.024mol): boric acid is 100:1 molar ratio to add boric acid, press concentrated nitric acid: Sr x Ba y Ca 1-x-y Mg z Zn 1-z al 10 o 17 :Eu 2+ (0.002mol) added concentrated nitric acid in a molar ratio of 5:1, according to absolute ethanol:Sr x Ba y Ca 1-x-y Mg z Zn 1-z al 10 o 17 :Eu 2+ (0.002mol) is added absolute ethanol at a molar ratio of 8:1, and the addition amount of polyethylene glycol is 0.5% by mass percentage. Will Eu 2 o 3 Dissolve in concentrated nitric acid (mass fraction 65%), then add absolute ethanol, then add polyethylene glycol (number average molecular weight 1200) to adjust the pH to 10, then add the required nitrate to obtain a transparent solution, then add boric acid and urea Stir continuously to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com