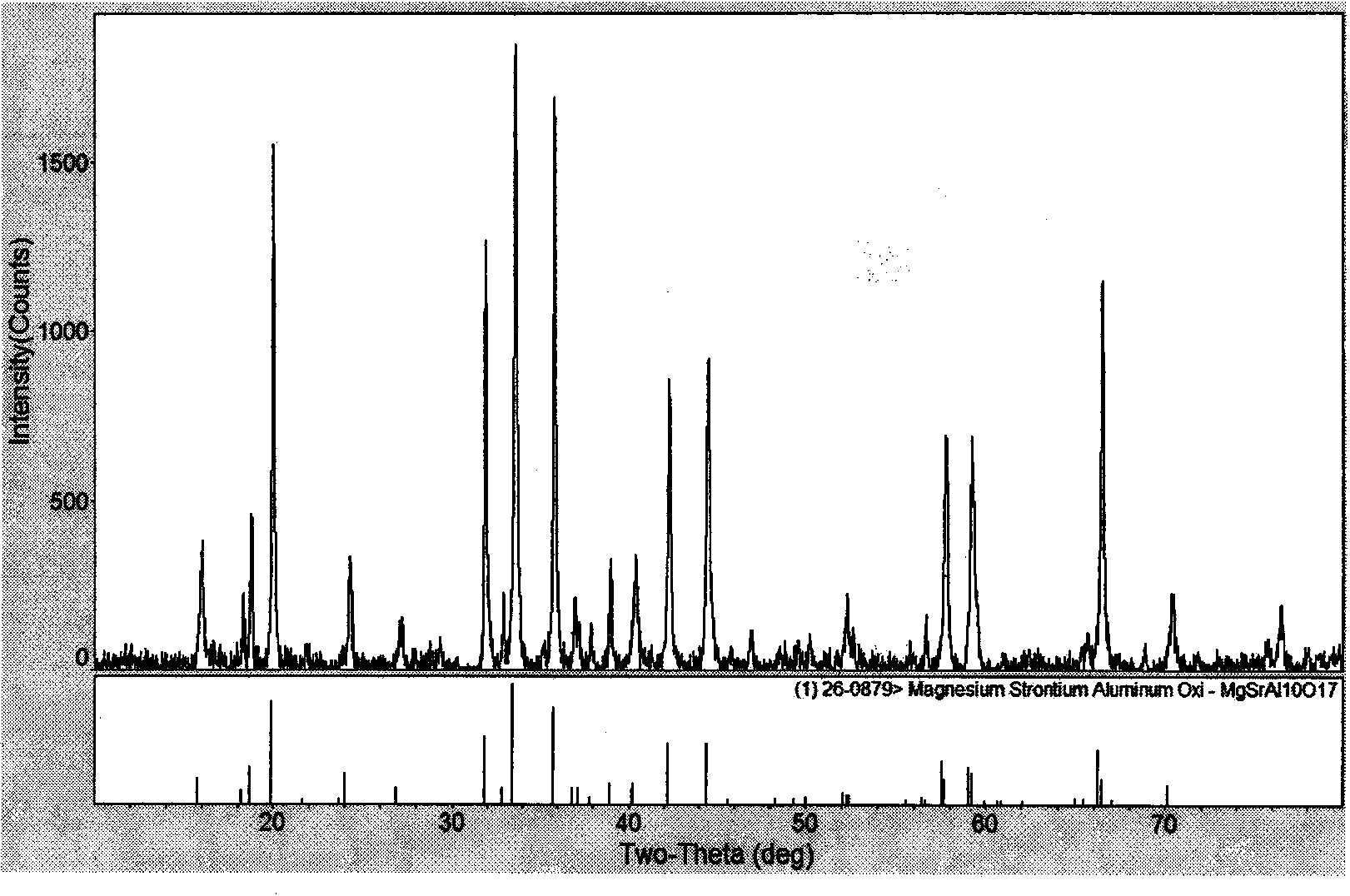

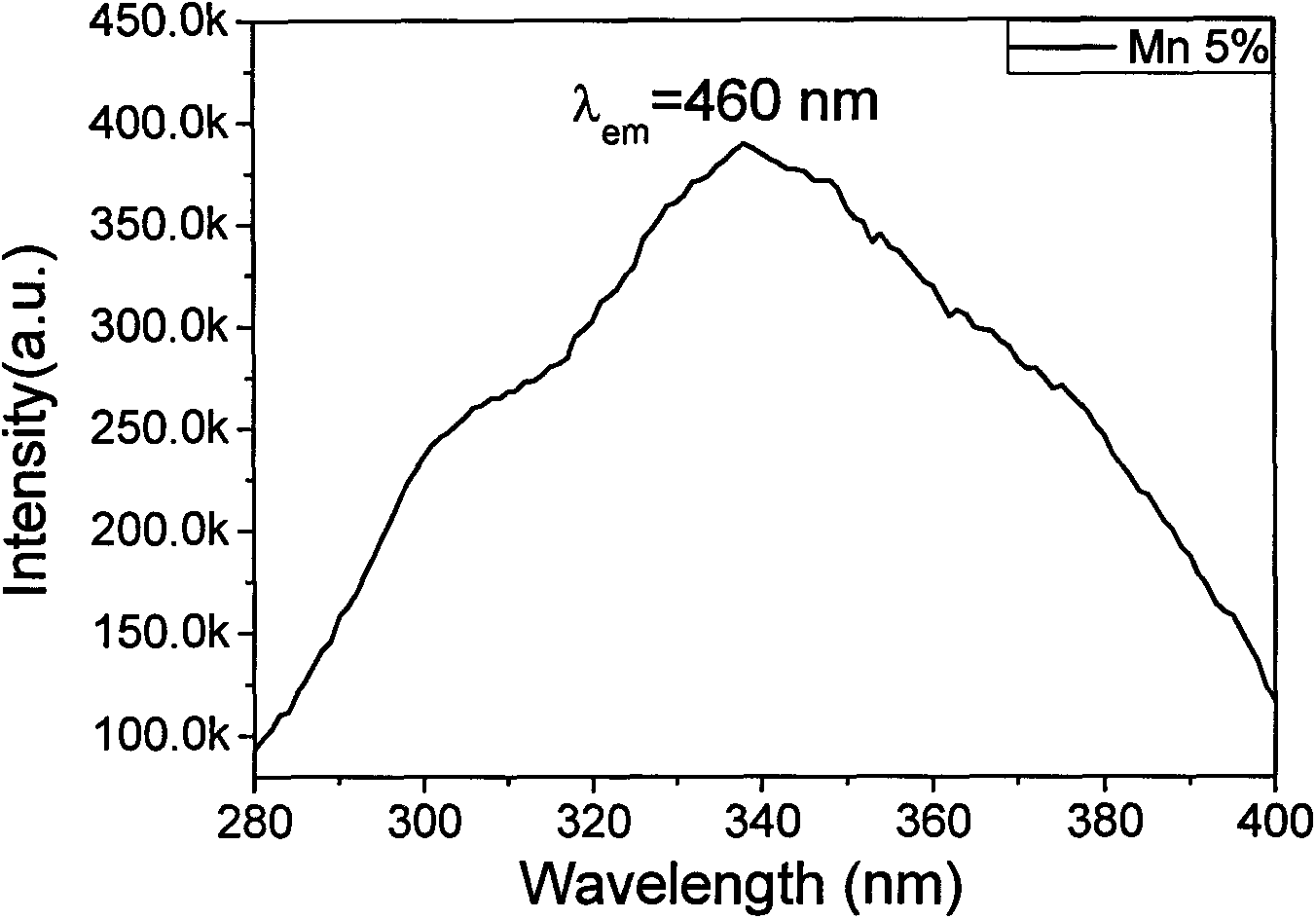

Ultraviolet-ray-excited SrMgAl10O17:Eu<2+>,Mn<2+> blue-green fluorescent powder

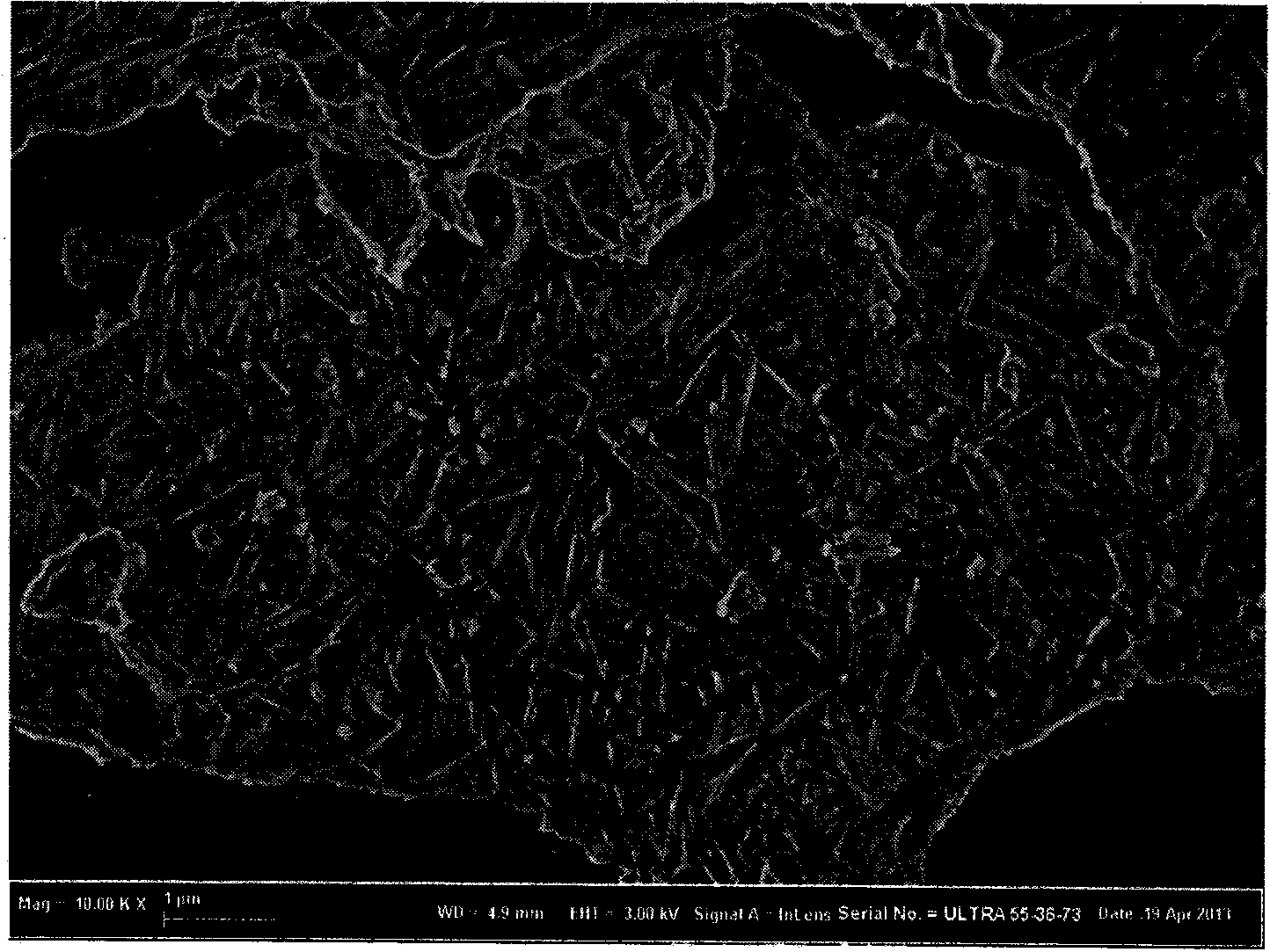

A technology of ultraviolet rays and fluorescent powder, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of single preparation method, coarse particle size of phosphor powder, and crystal form destruction, and achieve good chemical stability, high luminous efficiency, The effect of small particle size of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Accurately weigh 7.5027gAl(NO 3 ) 3 9H 2 O, 0.4021g Sr(NO 3 ) 2 , 0.5128g Mg(NO 3 ) 2 ·6H 2 O, 0.0178g Eu 2 o 3 and 0.0023g MnCO 3 ; Add urea according to the molar ratio of nitrate: urea of 1:1, add boric acid according to the molar ratio of nitrate: boric acid of 100:1, and fully mix the weighed reagents in an agate mortar;

[0024] Step 2: Put the reagent mixed well in the first step into a muffle furnace with an initial furnace temperature of 400°C for combustion. The entire combustion process lasts for about 1 to 2 minutes; take it out after 1 minute of heat preservation, cool and grind to obtain blue Green phosphor SrMgAl 10 o 17 : Eu 2+ , Mn 抖 .

Embodiment 2

[0026] Step 1: Accurately weigh 7.5027g Al(NO 3 ) 3 9H 2 O, 0.4021g Sr(NO 3 ) 2 , 0.5128g Mg(NO 3 ) 2 ·6H 2 O, 0.0178g Eu 2 o 3 and 0.0069g MnCO 3 ; Add urea according to the molar ratio of nitrate: urea of 1:2, add boric acid according to the molar ratio of nitrate: boric acid of 80:1, and fully mix the weighed reagents in an agate mortar;

[0027] Step 2: Put the reagent that has been fully mixed in the first step into a muffle furnace with an initial furnace temperature of 500°C for combustion. The entire combustion process lasts for about 1 to 2 minutes; take it out after 5 minutes of heat preservation, cool and grind to obtain blue Green phosphor SrMgAl10 o 17 : Eu 2+ , Mn 2+ .

Embodiment 3

[0029] Step 1: Accurately weigh 7.5027g Al(NO 3 ) 3 9H 2 O, 0.4021g Sr(NO 3 ) 2 , 0.5128g Mg(NO 3 ) 2 ·6H 2 O, 0.0178g Eu 2 o 3 and 0.0115g MnCO 3 ; Add urea according to the molar ratio of nitrate: urea of 1:3, add boric acid according to the molar ratio of nitrate: boric acid of 60:1, and fully mix the weighed reagents in an agate mortar;

[0030] Step 2: Put the reagent mixed well in the first step into a muffle furnace with an initial furnace temperature of 600°C for combustion. The entire combustion process lasts for about 1 to 2 minutes; take it out after 10 minutes of heat preservation, cool and grind to obtain Blue-green phosphor SrMgAl 10 o 17 : Eu 2+ ,Mn 2+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com