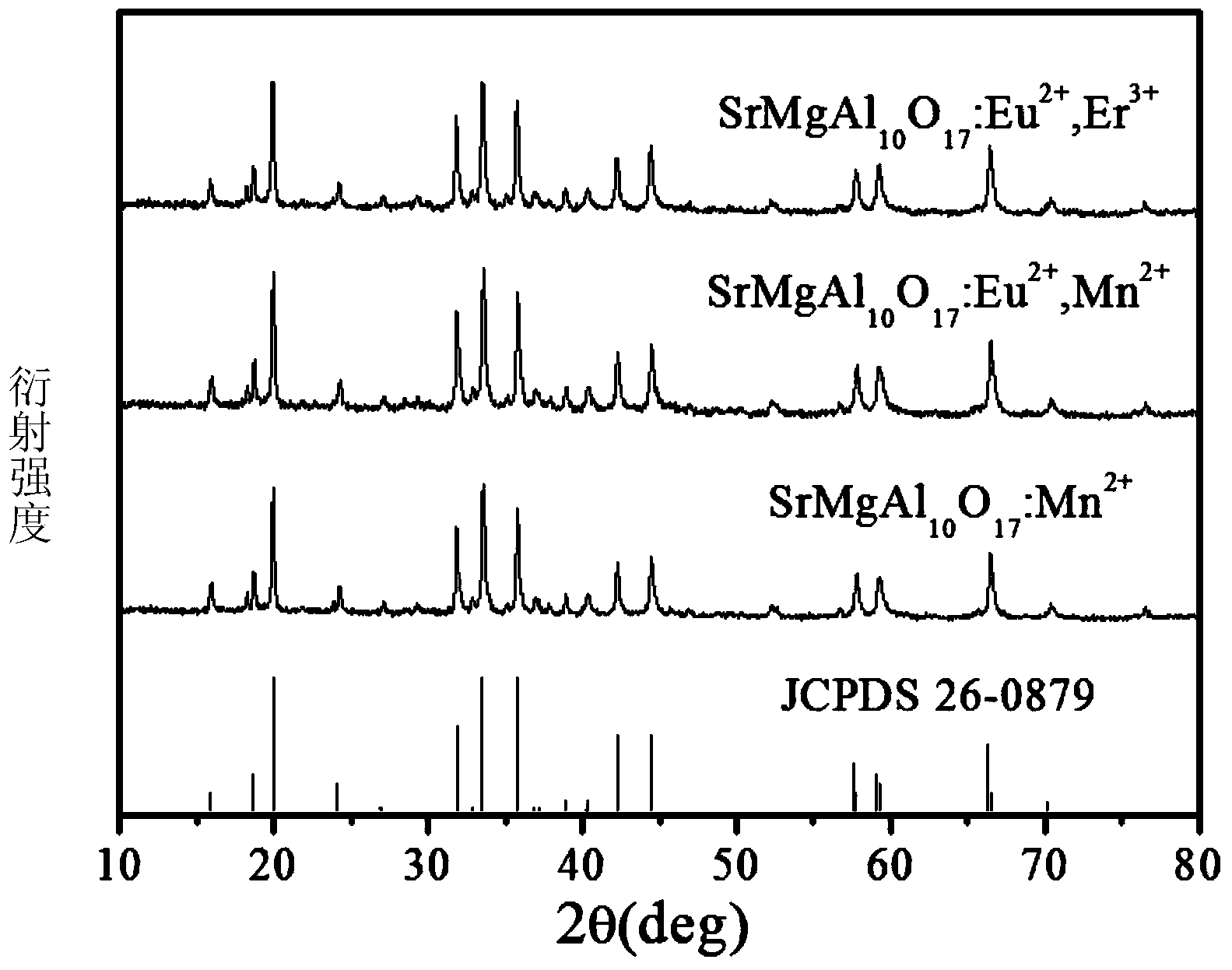

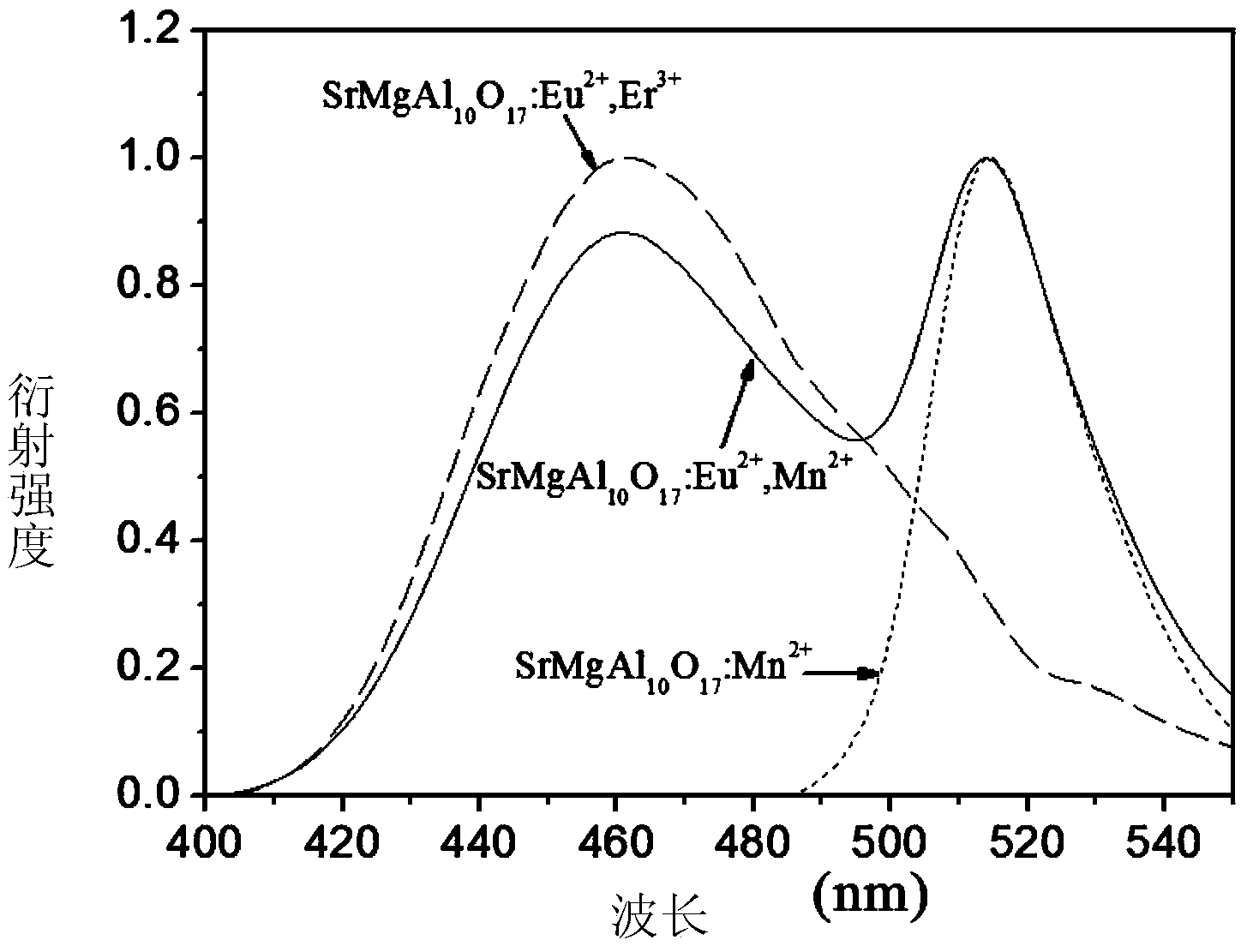

Method for preparing blue aluminate fluorescence powder via sol self-combustion method

A technology of blue fluorescent powder and self-combustion method, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of complex process, time-consuming and energy consumption, etc., and achieve the effect of simple process, uniform distribution and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Accurately weigh 7.5027g Al(NO 3 ) 3 9H 2 O, 0.3852g Sr(NO 3 ) 2 , 0.5128gMg (NO 3 ) 2 ·6H 2 O, 0.0320g Eu 2 o 3 and 0.0115g MnCO 3 . Then press nitrate [Al(NO 3 ) 3 9H 2 O, Sr(NO 3 ) 2 and Mg(NO 3 ) 2 ·6H 2 The amount of the total substance of the three]: urea is the urea added by weighing the molar ratio of 1:1.5, according to nitrate [Al(NO 3 ) 3 9H 2 O, Sr(NO 3 ) 2 and Mg(NO 3 ) 2 ·6H 2 The amount of the total substance of the three]: boric acid is the boric acid added by weighing the mol ratio of 100:1, by every mole of Al (NO 3 ) 3 9H 2 Add concentrated nitric acid in the amount of 50ml of O, that is, Al(NO 3 ) 3 9H 2 O is 0.02 mol, and the nitric acid in the added concentrated nitric acid is 0.015 mol, according to each mole of Al(NO 3 ) 3 9H 2 O is the amount that 150ml adds dehydrated alcohol, namely Al(NO 3 ) 3 9H 2 O is 0.02mol, and the absolute ethanol added is 0.05138mol.

[0030] Will Eu 2 o 3 , MnCO 3 Dissolve in co...

Embodiment 2

[0032] Accurately weigh 7.5027g Al(NO 3 ) 3 9H 2 O, 0.3852gSr(NO 3 ) 2 , 0.5128gMg (NO 3 ) 2 ·6H 2 O, 0.0320g Eu 2 o 3 and 0.0161g MnCO 3 ; Press nitrate [Al(NO 3 ) 3 9H 2 O, Sr(NO 3 ) 2 and Mg(NO 3 ) 2 ·6H 2 The amount of the total substance of the three]: urea is the urea added by weighing the molar ratio of 1:1.5, according to nitrate [Al(NO 3 ) 3 9H 2 O, Sr(NO 3 ) 2 and Mg(NO 3 ) 2 ·6H 2 The amount of the total substance of the three]: boric acid is the boric acid added by weighing the mol ratio of 100:1, by every mole of Al (NO 3 ) 3 9H 2 Add concentrated nitric acid in the amount of 50ml of O, that is, Al(NO 3 ) 3 9H 2 O is 0.02 mol, and the nitric acid in the added concentrated nitric acid is 0.015 mol, according to each mole of Al(NO 3 ) 3 9H 2 O is the amount that 150ml adds dehydrated alcohol, namely Al(NO 3 ) 3 9H 2 O is 0.02mol, and the absolute ethanol added is 0.05138mol.

[0033] Will Eu 2 o 3 , MnCO 3 Dissolve in concentra...

Embodiment 3

[0035] Accurately weigh 7.5027g Al(NO 3 ) 3 9H 2 O, 0.42326g Sr(NO 3 ) 2 , 0.5128gMg (NO 3 ) 2 ·6H 2 O, 0.0115g MnCO 3 ; Press nitrate [Al(NO 3 ) 3 9H 2 O, Sr(NO 3 ) 2 and Mg(NO 3 ) 2 ·6H 2The amount of the total substance of the three]: urea is the urea added by weighing the molar ratio of 1:1.5, according to nitrate [Al(NO 3 ) 3 9H 2 O, Sr(NO 3 ) 2 and Mg(NO 3 ) 2 ·6H 2 The amount of the total substance of the three]: boric acid is the boric acid added by weighing the mol ratio of 100:1, by every mole of Al (NO 3 ) 3 9H 2 Add concentrated nitric acid in the amount of 50ml of O, that is, Al(NO 3 ) 3 9H 2 O is 0.02 mol, and the nitric acid in the added concentrated nitric acid is 0.015 mol, according to each mole of Al(NO 3 ) 3 9H 2 O is the amount that 150ml adds dehydrated alcohol, namely Al(NO 3 ) 3 9H 2 O is 0.02mol, and the absolute ethanol added is 0.05138mol.

[0036] MnCO 3 Dissolve in concentrated nitric acid to obtain a transparent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com