Trunk injection insecticidal micro-emulsion granules for preventing and controlling tree pests, preparation method and application thereof

A microemulsion and insecticide technology, applied in the field of pesticides, can solve the problems of tree damage, secondary pollution, damage to trees, etc., and achieve good physical and chemical stability, good control effect, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

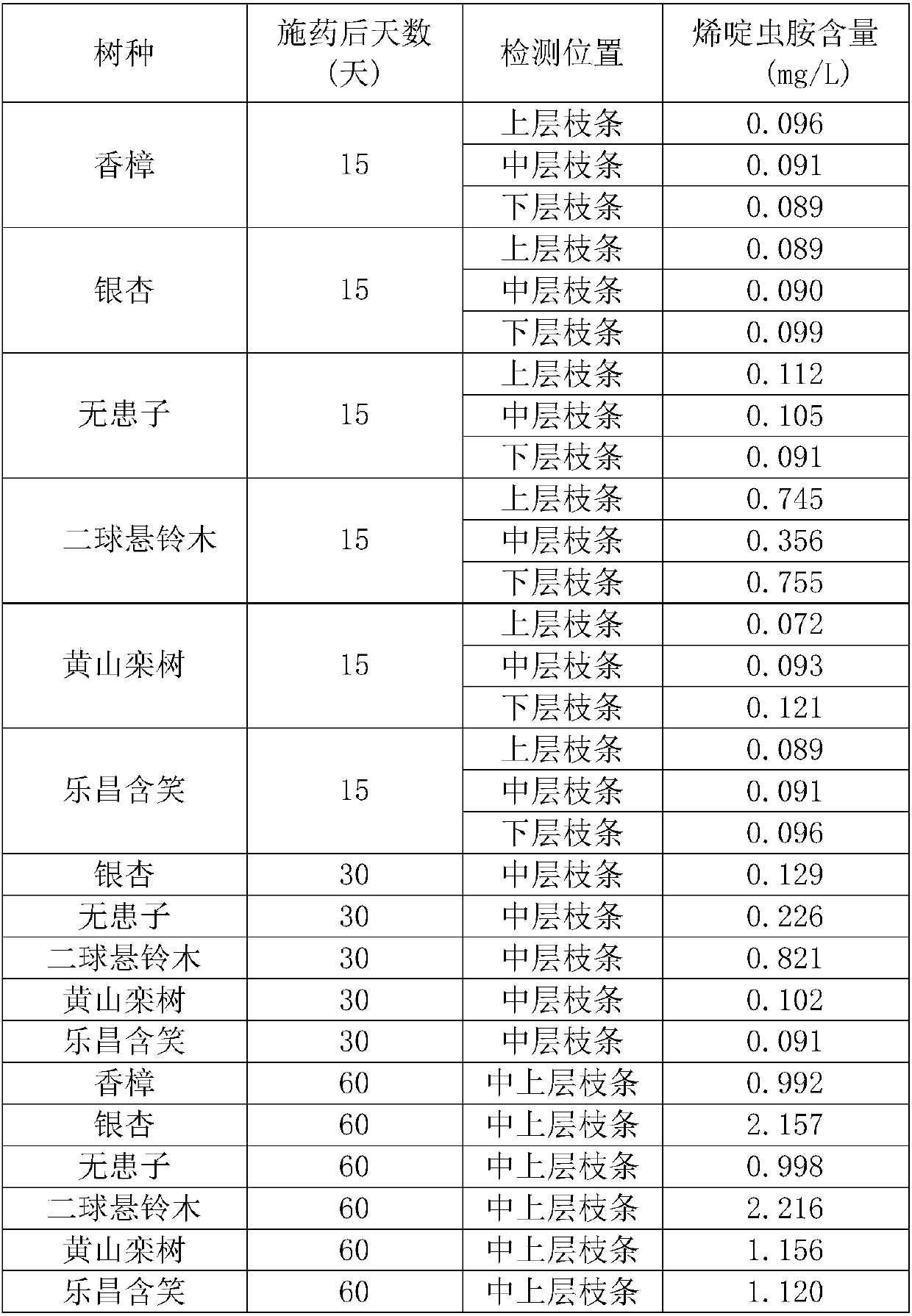

Image

Examples

preparation Embodiment 1

[0039] Dissolve 7.0g of active ingredients (wherein the active ingredients are 2.0g of emamectin benzoate and 5.0g of nitenpyram) in 5.5g of n-butanol, add 7.0g of emulsifier after heating and shaking to dissolve (wherein the emulsifier is 5.0g of alkyl Phenol ether phosphate and 2.0g castor oil polyoxyethylene ether) and fully stirred evenly to obtain an organic phase. Then take 5.0g of the organic phase, and add 11.0g of the filler (where the filler is 5.0g of D-(+)-lactose monohydrate, 5.0g of sodium benzoate and 1.0g of carboxymethyl cellulose), and stir well to the organic phase Mix evenly with the filler, and after the organic phase is completely absorbed by the filler, extrude and granulate to make cylindrical granules to obtain the insecticidal microemulsion granule for dry injection of the present invention.

preparation Embodiment 2

[0041] Dissolve 8.0g of active ingredients (wherein the active ingredients are 3.0g of methamectin and 5.0g of nitenpyram) in 5.5g of n-butanol, add 7.0g of emulsifier after heating and shaking to dissolve (wherein the emulsifier is 5.0g of alkyl Phenol ether phosphate and 2.0g castor oil polyoxyethylene ether) and fully stirred evenly to obtain an organic phase. Then take 5.0g of the organic phase, and add 11.0g of the filler (where the filler is 5.0g of D-(+)-lactose monohydrate, 5.0g of sodium benzoate and 1.0g of carboxymethyl cellulose), and stir well to the organic phase Mix evenly with the filler, and after the organic phase is completely absorbed by the filler, extrude and granulate to make cylindrical granules to obtain the insecticidal microemulsion granule for dry injection of the present invention.

preparation Embodiment 3

[0043] Dissolve 9.0g of active ingredients (wherein the active ingredients are 2.5g of emamectin benzoate and 6.5g of dinotefuran) in 5.5g of methanol, add 8.0g of emulsifier after heating and shaking to dissolve (wherein the emulsifier is 5.0g of alkylphenol ether phosphoric acid ester and 3.0g castor oil polyoxyethylene ether) and fully stirred to obtain an organic phase. Take 5.0g organic phase afterwards, and 11.0g filler (wherein filler is 5.0gD-(+)-lactose monohydrate, 5.0g sodium benzoate and 1.0g carboxymethyl cellulose) add wherein, fully stir until organic phase and The filler is mixed evenly, and after the organic phase is completely absorbed by the filler, it is extruded and granulated to make cylindrical granules to obtain the insecticidal microemulsion granule for dry injection of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com