A printed circuit board for computer and its manufacturing method

A technology for printed circuit boards and computers, applied in the directions of printed circuit components, printed circuit secondary processing, circuit thermal devices, etc., can solve the problems of printed circuit boards lack of heat dissipation structure, circuit pattern falling off, difficult heat dissipation needs, etc. The effect of heat dissipation, good installation and tightness, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

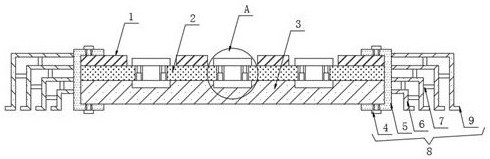

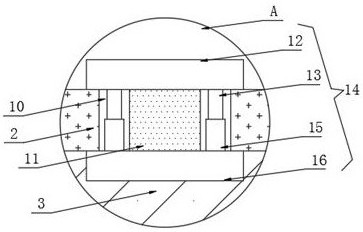

[0022] see Figure 1~2 , in an embodiment of the present invention, a printed circuit board for a computer includes a substrate 3, an insulating layer 2 affixed to the substrate 3, and a solder resist 1 uniformly sprayed on the insulating layer 2, and the interior of the insulating layer 2 is also installed with The circuit pattern 11, the two sides of the substrate 3 and the insulating layer 2 are respectively equipped with a cooling device 8, the cooling device 8 includes a screw 4, a mounting frame 5, a cooling plate 6, a heat pipe 7 and a mounting foot 9, and the mounting frame 5 is engaged with the resistance On both sides of the flux 1, the insulating layer 2 and the substrate 3, and the upper and lower surfaces of the mounting frame 5 are threadedly connected with screws 4, and the outside of the mounting frame 5 is fixedly fixed with four cooling plates 6 equidistantly from top to bottom. One end of the plate 6 is uniformly connected with mounting feet 9 perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com