Explosion-proof monitoring control method and system for low-temperature plasma organic waste gas treatment

A low-temperature plasma, organic waste gas technology, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problem of short-term and long-term simultaneous prevention and control of explosion risks, and achieve the effect of reducing explosion risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

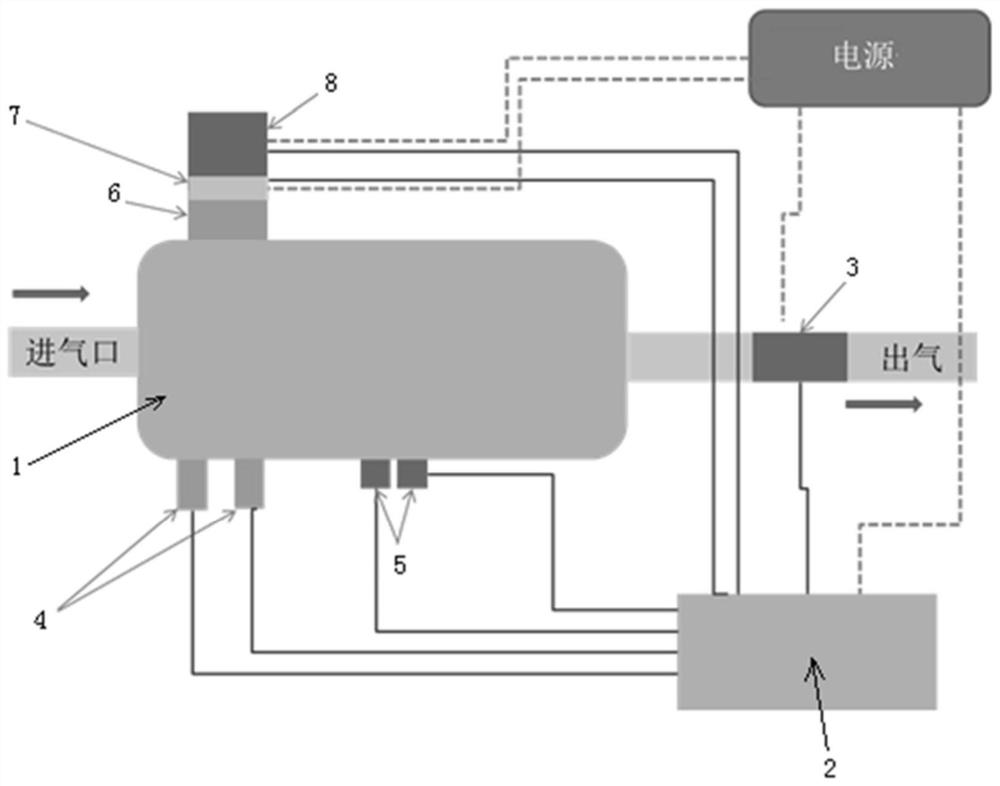

Method used

Image

Examples

example 1

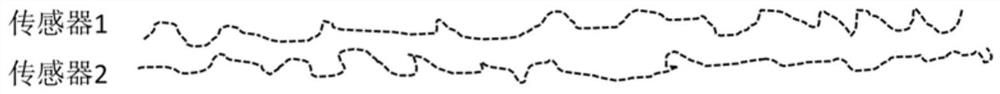

[0038] Example 1: Although the current gas temperature T is within the safe operating range, the total hydrocarbon concentration C of the gas has reached the lower limit of the explosive concentration, and the explosion condition is not met at present, but the temperature will continue to rise due to the change of the dielectric constant of the electrode blocking medium, then in In the near future, once the temperature exceeds the safe operating range, an explosion will occur immediately. In the present invention, when the gas total hydrocarbon concentration C has not yet reached the lower limit of the explosive concentration, but there is a risk, a corresponding anti-explosion control strategy will be adopted.

example 2

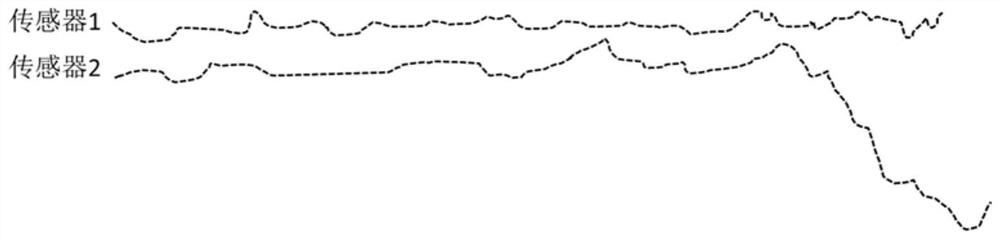

[0039] Example 2: Although the current gas total hydrocarbon concentration C is in the safe range (such as below 5% of the lower limit of the explosive concentration), the current gas temperature T exceeds the safe operating range, and the current explosion conditions are not satisfied. If it is not correct at this time, the gas temperature T will rise If the gas total hydrocarbon concentration C suddenly rises rapidly, and it is difficult to quickly reduce it, once the lower limit of the explosive concentration is reached, the explosion will occur immediately. In the present invention, when the gas temperature T exceeds the safe range, no matter whether the total hydrocarbon concentration C of the gas exceeds the limit or not, the shutdown and maintenance treatment is performed to eliminate the cause of the increase of the gas temperature T.

[0040] According to the risk level of different explosion safety hazards, implement corresponding explosion-proof control strategies: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com